5.4

Setting up control system, creating automation

project

è

Documentation of the control system

Example of Siemens SIMATIC S7-1200, TIA portal:

1. Open device and network view:

View

è

Double click “Devices & networks”.

2. Open “Network view”.

3. Open hardware catalog (“Catalog”).

4.Open “System control” (“PLC”) directory.

5. Drag system control (PCL/“CPU”) into the network view.

5.5

Insert PROFINET station (“Station”)

è

Documentation of the control system

Example of Siemens SIMATIC S7-1200, TIA portal:

1. Open “Devices & networks” view

è

Section 5.4).

2. Open “Network view”.

3. Open hardware catalog (“Catalog”).

4.Open “Other field devices” directory:

è

“PROFINET IO”

è

“Valves”

è

“Festo AG & Co. KG”

è

“Festo CTEU-PN”.

5. Select the symbol for the PROFINET station, i.e. of bus

node CTEU-PN and drag it into the network view.

6. Open “Connections” view.

7. Connect bus node CTEU-PN to the control system:

Click bus node symbol, press and hold down button and

drag mouse pointer to system control symbol.

8. Select connection: “Connections”

è

“PROFINET IO

system”.

5.6

Assigning a “Device Name”

è

Documentation of the control system

With the device name, you can address the bus node and

the connected product (“I-port device”) directly, e.g. in

your automation program.

5.7

Assigning or changing IP address

è

Documentation of the control system

In most cases, the control system handles the assignment

of an IP address.

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Observe the basic addressing rules for the allocation

of the IP address, e.g. with respect to the use of

private or public address ranges.

Check that the IP address can be used in the automa

tion network.

Ensure that there is no duplication of IP addresses in

use.

5.8

Configuring field devices (“I-port devices;)

è

Documentation of the control system

Example of Siemens SIMATIC S7-1200, TIA portal:

1. Open “Devices & networks” view

è

Section 5.4).

2. Open “Device view”.

3. Open hardware catalog (“Catalog”).

4.Open “Other field devices” directory.

5. Configure field devices:

Drag the symbols for the connected products (“I-port

devices”) into the “Device overview”.

5.9

Changing start addresses of inputs/outputs

è

Documentation of the control system

In most cases, the control system handles the assignment

of the input/output addresses and the diagnosis ad

dresses.

5.10

Setting up PROFINET “Fast Start-up” function

è

Documentation of the control system

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When using the PROFINET “Fast Start-up” function

(FSU), “Crossover Detection”, “Auto-MDI” and

“Autocrossover/Autonegotiation” are

not

available.

Crossover detection -

disable

:

– in the hardware configuration of

all

network

participants

– in the hardware configuration of the network

neighbor (“Partner Port”).

Deactivation of the crossover detection changes

changes the pin allocation of the next network port TP2

to “crossover”.

Select interconnecting cable dependent on pin

assignment of network connection of product

connected to TP2:

– Crossover cables with

identical

assignment of

ports

– Patch cables with

different

assignment of ports.

Example of Siemens SIMATIC S7-1200, TIA portal:

1. Call up “Device overview” :

Open “Project navigation” window

è

Devices

è

Device view

è

Device overview

è

Module

è

CTEU-PN.

2. Click “PN-IO Interface” module.

3. Call up interface options:

Window for “PN-IO Interface [Module]”

è

Properties

è

General

è

Advanced options

è

Interface options.

4.Enable interface option “Prioritized start-up (tick

boxes).

5. Call up port options:

Window “PN-IO Interface [Module]”

è

Properties

è

General

è

Advanced options

è

“Port 1 [X1 P1 R]”

and/or “Port 2 [X1 P2 R]”

è

Port options.

6. Under “Connection”,

disable

crossover detection

(“Autonegotiation”) on network ports TP1

and

TP2.

5.11

Set parameterisation

è

Documentation of the control system

You can set the characteristics of connected products

individually using parameterisation (“Module paramet

erisation”), e.g. input debounce time, signal extension

time, product monitoring, (forwarding of diagnostic mes

sages), settings for error situations (“Fail-state” mode).

Parameterisation for “I-port device” 1 (X1) and “I-port

device” 2 (X2) can be set separately.

Parameter

1)

Function

Port settings

2)

Example “Universal device 256DIO”

Tool Change Mode

Tool change mode:

– “Tool Change Mode” enabled:

The process data image rigidly assigns

address spaces for input and output

data (addressed) – regardless of which

product is connected (“I-port device”),

meaning that the connected products

(e.g. tools) can be interchanged without

the need for any configuration changes.

– “Tool Change Mode” disabled:

The “I-port device” detected at start-up

is adopted by the PROFINET configura

tion. The assignment (addressing) of in

put and output data in the process data

image depends on the connected

product.

Suppress all dia

gnostic messages

No forwarding of diagnostic messages via

the network

Suppress

diagnostic message

“No load voltage”

No forwarding of diagnostic message

“No load voltage”

3)

via the network

4)

(“Suppress missing load voltage diagnostic

messages”)

Fail-state

The “Fail-state” mode governs the charac

teristics of the bus node and the connected

products in the event of any communica

tion errors arising:

– Reset outputs (“Outputs reset”): The

outputs are reset.

– Outputs “Hold last state” (“Outputs

Hold last state”): The outputs hold their

last state.

The selected setting applies to all outputs.

The “Fail-state” setting also applies to the

“Idle state” operating state:

– The “Idle state” is adopted by the con

trol system on request. At this point, the

control system is in “Stop mode”.

– Input data continue to be transmitted

while the system is in “Idle state”.

I-port device parameter

2)

Example “Universal device 256DIO”

Byte 0 ... Byte 7

Tunneling of product-specific parameters

è

Documentation about the connected

product

1) Siemens SIMATIC S7-1200, TIA portal: Module parameter(s)

2) The available parameters depend on the connected product.

3) Monitoring for undervoltage of load voltage power supply to

outputs/valves U

OUT/VAL

(“Undervoltage U

OUT/VAL

”)

4) Diagnostic messages “No load voltage” are only generated once,

whenever the connected product is monitoring load voltage and

repor ts this status to the bus node.

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional test

– The LED

NF

is OFF (subject to fault-free communica

tion between control system and bus node).

– The LED

TP1

or

TP2

lights up green (

è

Section 7).

– Siemens SIMATIC S7-1200, TIA portal: In the

columns for “I address” and “O address”

respectively, the address entries are located (start

addresses for the inputs/outputs).

– Check availability of the network participants:

Menu “online”

è

“Accessible devices”

è

Check list

ing of available network participants for complete

ness (“Accessible devices in target subnet”).

6 “Identification and Maintenance”

è

Documentation of the control system

The “Identification and Maintenance” (I&M) function of

fers uniform, manufacturer-independent access to

product-specific information.

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manually updated I&M details, e.g. about the firmware

and software state of the bus node can differ from the

details on the product nomenclature.

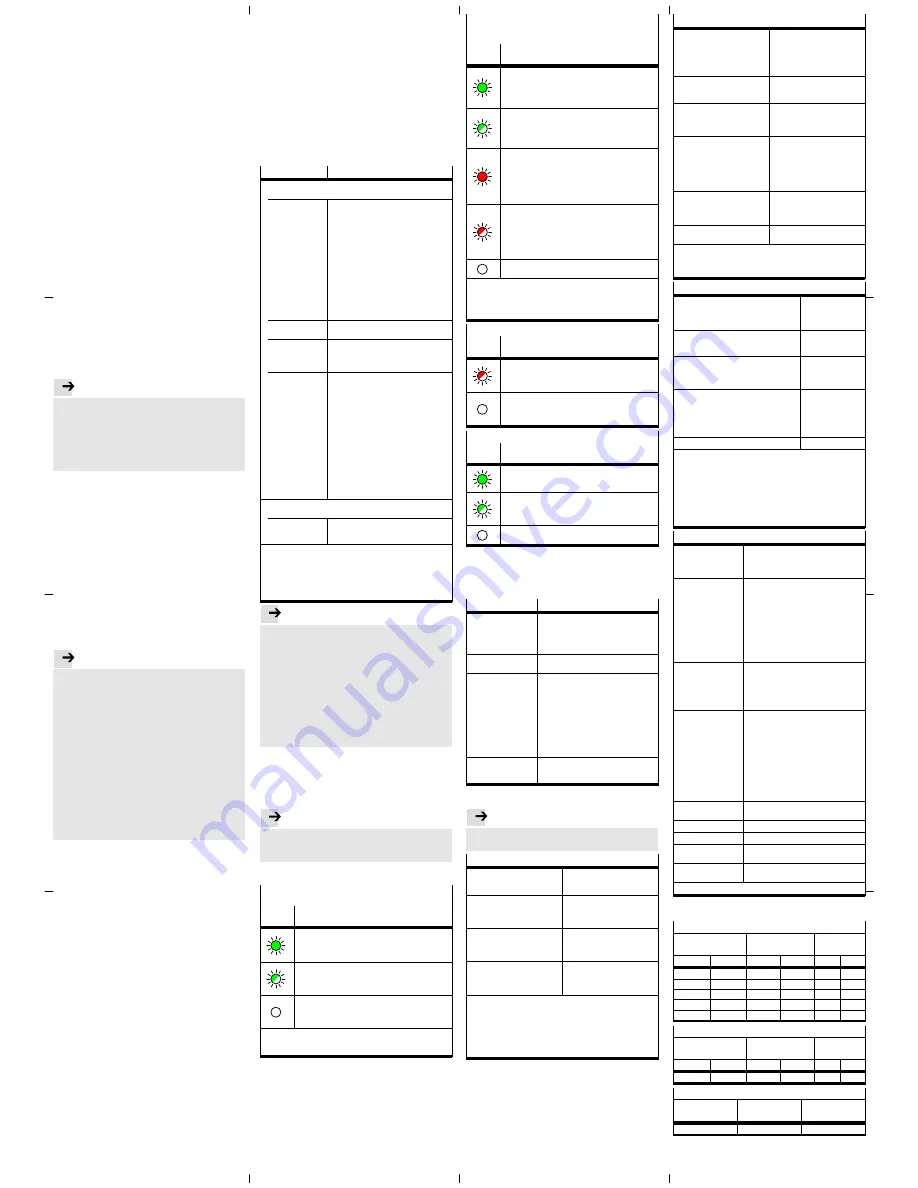

7 Diagnostics

PS – Status of the operating voltage supply

(power system)

LED

display

Status and significance

LED illuminated green:

– normal operating status

– Operating voltage is ON (within permitted range)

– Load voltage is ON (within permitted range)

1)

LED flashes green (flashing frequency: 1 Hz)

– Operating voltage is below the required voltage

– Load voltage is below the required level

1)

– Short circuit at the I-port

1)

LED is off:

– Operating voltage not present

– Operating voltage is below the voltage required for

diagnostic functions

1) This display only relates to the status of the load voltage if the

the connected product is monitoring the load voltage and

repor ts its status to the bus node.

X1 and X2 – Status of internal communication between

the bus node and the connected product

(“I-port device” 1 or “I-port device” 2)

1)

LED

display

Status and significance

LED illuminated green:

– normal operating status

– “I-port device” 1 or 2 is connected up correctly

– Operating and load voltage are connected (within

permitted range)

2)

LED flashing green:

– Status of diagnostics

– Undervoltage at system or additional power supply

– Connection between the bus node and the “I-port

device” is OK

LED illuminated red:

– “I-port device” is connected up correctly, but the

internal communication is in a fault state

– After start-up, wrong “I-port device” is connected up

(not the “I-port device” specified in the control

system hardware configuration, or a product not

compatible with I-port)

LED flashing red:

– During commissioning, incorrect I-port device

connected (non-I-port-compatible device)

– If only LED X1 flashes red: error in the bus node

– If X1 and X2 flash red simultaneously: no product

connected to the bus node (at least one I-port device

is required)

LED is off:

– No product connected to the bus node

1) Accessory with two I-port interfaces required to connect up two

products

2) This display only relates to the status of the load voltage if the

the connected product is monitoring the load voltage and

repor ts its status to the bus node.

NF – Network status/network failure

LED

display

Status and significance

LED flashing red:

– Communication error

– Communication between control system and bus

node is malfunctioning or interrupted.

LED is off:

– normal operating status

– Communication between control system and bus

node is OK

TP1/TP2 – Connection status (“Link” 1 or “Link” 2)

LED

display

Status and significance

LED illuminated green:

– normal operating status

– Network connection is OK

Both LEDs, TP1 and TP2 flash green:

– To locate the connected product (“module location”),

e.g. during hardware configuration of control system

or for troubleshooting

LED is off:

– No network connected

8 Maintenance

No specific measures

9 Glossary

Term/abbreviation Function

FSU

PROFINET function “Fast Start-up” also

known as “Prioritized Start-up” or “Fast

reboot”; operating mode of bus node,

assures fast rebooting of network

participants (“IO devices”)

PROFIenergy

PROFIenergy facilitates energy

management settings

PROFINET

Network and field bus system based on

Industrial Ethernet for data interchange

between a primary control system

(industry PC, PCL or “IO controller”),

network participants (“IO devices”) and

field devices (“Field Devices”), e.g. valve

terminals or drives

è

www.profinet.com

è

www.profibus.com/download/

è

PROFINET System Description,

Technology and Application

PLC

Programmable logic controller, also

referred to as system controller or

controller for short (PLC)

10 Technical data

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical data for the connected products can be ob

tained from the product documentation.

Electrical properties

Protection class through housing

(in accordance with

IEC/EN 60529/EN 60529)

IP65/IP67

1)2)

Protection against electric shock

(protection against direct and

indirect contact to

IEC 60204-1/EN 60204-1)

through the use of PELV circuits

(Protected Extra-Low Voltage)

Separation

Network connections for

operating voltage power supply

U

EL/SEN

Galvanically separated through

transformer (up to 500 V)

Electromagnetic compatibility

(EMC)

3)

– Emitted interference

– Resistance to interference

See declaration of conformity

è

www.festo.com

1) Requirement: Bus node mounted completely, plug connector in

the plugged-in status or provided with cover cap.

2) Connected products may only satisfy a lower degree of

protection.

3) The product is intended for use in an industrial environment.

Outside of industrial environments, e.g. in commercial and

mixed-residential areas, actions to suppress interference may

have to be taken.

General mechanical attributes

Vibration and shock resistance

(in accordance with

IEC/EN 60068)

1)

– Vibration (part 2-6)

– Shock (part 2-27)

– Continuous shock (part 2-27)

Severity level (SL)

1)

for wall or

H-rail mounting

– Wall: SG2; H-rail: SG1

– Wall: SG2; H-rail: SG1

– Wall and H-rail: SG1

Temperature range

2)

– Storage/transpor t

– Operation

–20 … +70 °C

–5 … +50 °C

Corrosion protection

The product is intended for

indoor application in typical

industrial atmosphere: Avoid

condensation.

Materials

– housing

– fibre-optic cable

– Threaded sleeve M12

– Threaded bush M3

– Seals

– Screws

RoHS-compliant

Reinforced polyamide

Polycarbonate

Brass, galvanically nickel-plated

brass,

Nitrile rubber

Galvanised steel

Dimensions

– Width

– Length

– Height

40 mm

91 mm

50 mm

Weight (bus node without cables

and sub-assembly)

94 g

1) Explanation of the severity level

è

Table “Explanation on

vibration and shock – severity level”

2) Connected products may only satisfy a less extensive

temperature range.

Power supply

Operating voltage for bus node and

connected products

1)

– Nennwert

– tolerance range

24 V DC

18 … 30 V DC

2)

Load voltage for bus node and connected

products

1)

– Tolerance range

18 … 30 V DC

2)

Intrinsic current consumption at nominal

operating voltage 24 V DC

from operating voltage supply for

electronics/sensors (U

EL/SEN

)

Typically 80 mA

(internal electronics)

Power rating of operating and load voltage

power supplies

1)3)

– Bus node on the connected product

(e.g. valve terminal)

– Bus node on the decentralised electric

sub-base CAPC

max.

4 A

max.

2 A

per “I-port device”

4)

Power failure buffering

10 ms

1) Separate and external fuses are required for the operating and

load voltage power supplies (no bus node-internal overload and

polarity reversal protection for the connected products).

2) The tolerance range is dependent on the connected products.

3) Total power rating of operating and load voltage power supplies

PS and PL (residual current), maximum permitted current

consumption of bus node and connected products

4) Total power rating of operating and load voltage power supplies

PS and PL (residual current), maximum permitted current

consumption for each “I-port device”

Network-specific characteristics

Network protocol

PROFINET IO:

– based on Industrial Ethernet

– based on the standard Ethernet

protocol (IEEE 802.3)

Suppor ted protocol

characteristics and

protocol functions

(selection)

– Cyclical data exchange “in real time”,

without cycle synchronicity (Real-Time,

RT) or with cycle synchronicity

(Isochronous Real Time, IRT)

1)

– Link Layer Discovery Protocol (LLDP)

– Simple Network Management Protocol

(SNMP)

– Fast Start-up (FSU)

– PROFIenergy

– Shared device

– Media Redundancy Protocol (MRP)

System-specific

functions

– Diagnosis information (system

diagnosis, undervoltage,

communication errors)

– Web server (status of bus node and

connected products, serial number,

configuration)

Specification

Selection of directives and norms

regarding PROFINET:

– PROFINET installation guidelines

(“PROFINET Installation Guide”,

“Installation Guideline PROFINET

Part 2…”).

– IEC 61158

– IEC 61784

– IEC 61918

For additional information:

è

www.profinet.com

è

www.profibus.com/download/

Transmission

technology

Switched Fast EtherCat;

Version 100BaseTX acc. to IEEE 802.3

Transmission rate

100 Mbit/s

Network connections

2 x socket, M12, D-coded, 4-pin

Crossover detection,

auto-negotiation

Auto-M DI

Max. address volume

inputs/outputs

64 bytes E, 64 bytes A,

independent of operating mode

1) IRT is only available via LAN

Explanation on vibration and shock – severity level

Vibration load

Frequency range

[Hz]

Acceleration

[m/s

2

]

Displacement

[mm]

SL1

SL2

SL1

SL2

SL1

SL2

2 … 8

2 … 8

–

–

±3.5

±3.5

8 … 27

8 … 27

10

10

–

–

27 … 58

27 … 60

–

–

±0.15

±0.35

58 … 160

60 … 160

20

50

–

–

160 … 200

160 … 200

10

10

–

–

Shock load

Acceleration

[m/s

2

]

Duration

[ms]

Shocks per

direction

SL1

SL2

SL1

SL2

SL1

SL2

±150

±300

11

11

5

5

Continuous shock load

Acceleration

[m/s

2

]

Duration

[ms]

Shocks per

direction

±150

6

1000