4

Electrical installation

4.1 Connector pin assignments

The CMMP-AS-…-M3 motor controller is connected to the supply voltage, motor,

external braking resistor and the holding brake in accordance with

è

Hardware

description.

Note

If the polarity of the operating voltage connections is reversed, or if the operat

ing voltage is too high or the operating voltage and motor connections are re

versed, the CMMP-AS-…-M3 motor controller will be damaged.

Overview of connections

[X1]

I/O communication

[X2A]

Resolver

[X2B]

encoder

[X4]

CAN bus

[X6]

Motor

[X9]

Power supply

[X10]

Increment generator input

[X11]

Increment generator output

[X18]

Ethernet interface

[X19]

USB interface

1)

Connection of the PC for commissioning.

è

The cable screening of the motor cable must also be connected to the screening

clamp of the motor controller.

Observe the instructions for safe and EMC-compliant installation

è

Hardware

description.

The main pin allocations can be found as stickers which are included in the scope

of delivery.

5

Commissioning

è

Information for commissioning can be found in the corresponding documenta

tion for the motor controller

è

section 2.2. The following sections provide a con

nection overview and an overview for checking the operating status of the product.

Connecting the motor

1. Insert the plug of the motor cable into the corresponding socket on the motor

and tighten.

2. Insert the PHOENIX plug into the socket [X6] on the device.

3. Clamp the cable shields to the shield terminals (not suitable as strain-relief ).

4. Insert the plug of the encoder cable into the encoder output socket on the mo

tor and tighten.

5. Insert the D-SUB plug into socket [X2A] resolver or [X2B] encoder of the device

and secure the locking screws.

6. Check all plug connectors once again.

Connecting the power supply

1. Make sure that the power supply is switched off.

2. Insert the PHOENIX plug into the socket [X9] on the motor controller.

3. Connect the PE cable of the mains supply to the PE earth socket.

4. Connect the 24 V connections using an appropriate power supply unit.

5. Connect the power supply unit.

6. Check all plug connectors once again.

Connect the PC

1. For commissioning you will need the FCT with CMMP-AS plug-in which can be

found on the CD-ROM supplied with the motor controller or at

è

www.festo.com/sp.

Installation: Launch “Start.exe”; administrator rights are required for installa

tion of the FCT (see Readme.txt).

2. Connect the PC to the motor controller via USB or Ethernet

è

Hardware descrip

tion.

Check readiness for operation

1. Make sure that the controller enable is switched off (controller enable: DIN 5

at [X1]).

2. Switch on the power supplies for all devices. The READY LED on the front of the

device should now light up.

è

If the READY LED lights up red, it indicates a fault. If an “E” appears in the

seven-segment display followed by a sequence of numbers, this is an error mes

sage and you must rectify the cause of the error

è

Hardware description.

If there is no display

1. Switch of the power supply.

2. Wait 5 minutes to allow the intermediate circuit to discharge.

3. Check all connecting cables.

4. Check the functionality of the 24 V power supply.

5. Switch on the supply voltage again.

6. If there is still no display

è

device is defective

6

Service functions and diagnostic messages

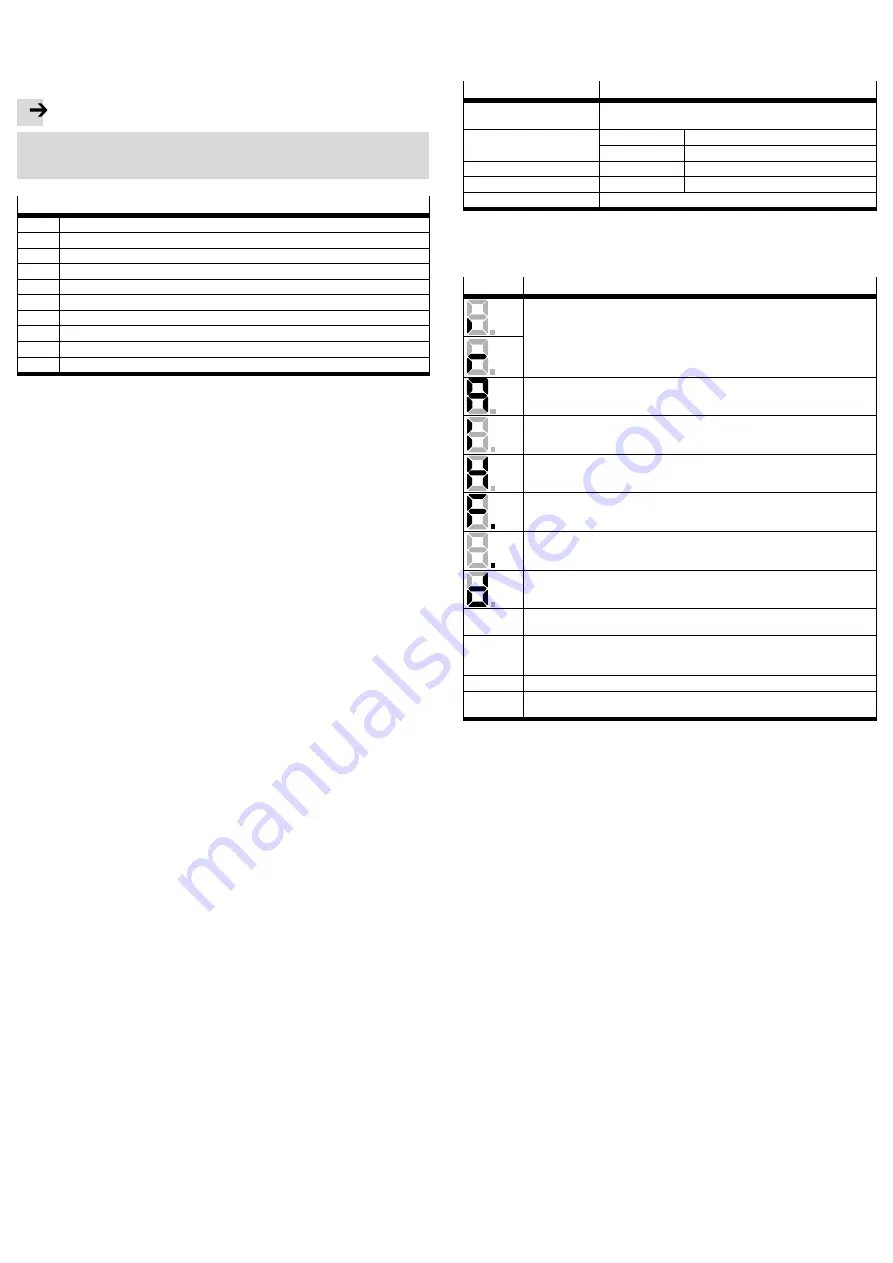

6.1 Operation and display components

The CMMP-AS-…-M3 motor controller has three LEDs on the front and a seven-seg

ment display for indicating the various operating states.

Element

Function

Seven segment display

Displays the operating mode and an error code should an error

occur

è

LED1

Lights up green

Ready status

Lights up red

Error

LED2

Lights up green

Controller enable

LED3

Lights up yellow

CAN bus status display

RESET button

Hardware reset

6.2 Seven segment display

The display and the meaning of the symbols shown are illustrated in the following

table:

Display

Meaning

The outer segments “rotate” on the display in the speed control operating mode.

The display depends on the current actual position or speed.

The central bar is also active when the controller release is active.

The CMMP-AS-…-M3 motor controller still needs to be parameterised.

(Seven-segment display = “A”)

Controlled torque mode.

(Seven-segment display = “I”)

“H”: (Only applicable when using a safety module) a safety function is initiated

è

safety module description.

“F”: Indicates that firmware is loaded in the flash memory.

“.”: Boot loader active

“d”: Indicates that a parameter set is loaded from the SD card into the controller.

P xxx

Positioning (“xxx” stands for the position number)

The numbers are shown in succession

PH x

Homing: “x” stands for the respective phase of the homing procedure (0: search

phase, 1: creep phase, 2: travel to zero position). The numbers are shown in suc

cession

E xxy

Error message with main index “xx” and subindex “y”

-xxy-

Warning message with main index “xx” and sub-index “y”. Warnings are shown at

least twice on the seven-segment display.

6.3 Diagnostic messages

If an error occurs, the CMMP-AS-…-M3 motor controller displays a diagnostic mes

sage cyclically in the seven-segment display of the motor controller

CMMP-AS-…-M3. The error message consists of an E (for Error), a main index and a

subindex, e.g.: E 0 1 0.

Warnings have the same number as an error message. The difference is that a

warning is displayed with a prefixed and suffixed hyphen, e.g.: .

- 1 7 0 -

.

The meanings and the measures for the message groups are summarised in the

following table. A complete list of all error messages can be found in the

è

Hard

ware description.

7

Repair and disposal

è

Repair of the motor controller is not permissible. If necessary, replace the motor

controller.

è

Observe the local regulations for environmentally-friendly disposal of electronic

modules.