Job Sheet 3 – Variable-Speed Belt Drives

52

© Festo Didactic 54977-3C

49.

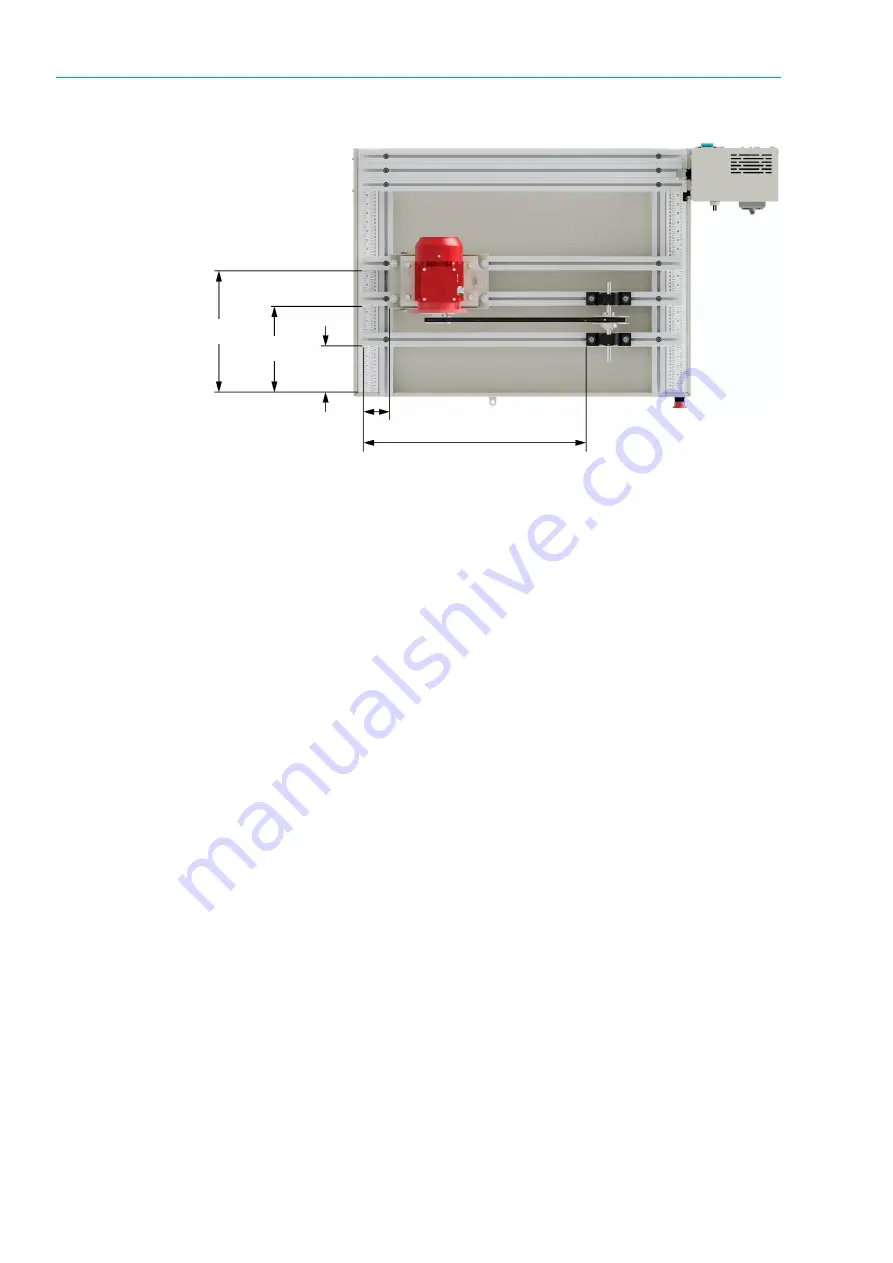

Move the pillow block bearings to the positions shown in Figure 40.

Figure 40. Second workstation setup for Job Sheet 3.

50.

Evenly move the pillow block bearings as far as possible from the motor until

they can no longer be moved further. This will ease the tensioning of the belt

that will be performed later in this job.

51.

Verify the vertical angular alignment by laying a combination square against

the face of the driving pulley. Note the position of the bubble.

52.

Lay the combination square against the face of the driven pulley and note the

position of the bubble.

53.

Adjust the vertical angular alignment so that the position of the bubble on the

driven pulley coincides with its position on the driving pulley. Insert shims

under the pillow block bearings as required.

a

The bubble does not need to be perfectly centered, but it must be at the same

position for both pulleys.

54.

Perform the Variable-pitch pulley alignment procedure.

55.

Adjust the belt tension using the belt tension tester, and the motor mounting

base to the recommended deflection force shown in Table 7 above.

56.

Perform the Start-up procedure.

57.

Perform the Testing the system procedure.

7.5 cm

63.0 cm

13 cm

24.5 cm

34.5 cm

Содержание Belt Drives 2

Страница 1: ...Industrial Maintenance Belt Drives 2 Course Sample 54977 3C ...

Страница 6: ......

Страница 10: ......

Страница 12: ......

Страница 13: ...Sample Extracted from Job Sheets Instructor ...

Страница 14: ......

Страница 22: ......