ECONCEPT ST

39

EN

cod. 3540S814 -

/201

(Rev. 00)

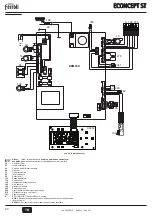

Accessing the electrical terminal block

Follow the instructions given in fig. 18 to access the electrical connections terminal block.

The layout of the terminals for the various connections is also given in the wiring diagram

in fig. 34.

fig. 18 - Accessing the terminal block

3.6 Fume ducts

Important

The unit is a "C type" with sealed chamber and forced draught, the air inlet and fume out-

let must be connected to one of the following exhaust/inlet systems. The unit is approved

for operation with all the Cxy flue configurations indicated on the data plate (some con-

figurations are given by way of example in this section). Some configurations may be ex-

pressly limited or not permitted by law, standards or local regulations. Before proceeding

with installation, check and carefully observe the above prescriptions. Also, comply with

the provisions on the positioning of wall and/or roof terminals and the minimum distances

from windows, walls, vents, etc.

B

This C-type unit must be installed using the inlet and fume exhaust ducts supplied by the

manufacturer in accordance with UNI-CIG 7129/92. Failure to use them automatically

invalidates every warranty and relieves the manufacturer of any liability.

A

For fume exhaust pipes longer than 1 metre, during installation take in account

the natural expansion of the materials when the boiler is operating.

To prevent deformations, leave an expansion space of approx. 2 ÷ 4 mm for

every metre of pipe.

Connection with coaxial pipes

fig. 19 - Examples of connection with coaxial pipes (

= Air /

= Fumes)

For coaxial connection, fit the unit with one of the following starting accessories. For the

wall hole dimensions, refer to the figure on the cover. Any horizontal sections of the fume

exhaust must be kept sloping slightly towards the boiler, to prevent condensate from

flowing back towards the outside and causing dripping.

fig. 20 - Starting accessory for coaxial ducts

Before proceeding with installation, check with table 2 that the maximum permissible

length is not exceeded, bearing in mind that every coaxial bend gives rise to the reduc-

tion indicated in the table. For example, a Ø 60/100 duct comprising a 90° bend + 1 hor-

izontal metre has a total equivalent length of 2 metres.

Table. 2 - Max. length coaxial ducts

Connection with separate pipes

fig. 21 - Examples of connection with separate pipes (

= Air /

= Fumes)

For the connection of separate ducts, fit the unit with the following starting accessory:

fig. 22 - Starting accessory for separate ducts

Before proceeding with installation make sure the maximum permissible length has not

been exceeded, by means of a simple calculation:

1.

Completely establish the layout of the system of split flues, including accessories

and outlet terminals.

2.

Consult the table 4 and identify the losses in m

eq

(equivalent metres) of every com-

ponent, according to the installation position.

3.

Check that the sum total of losses is less than or equal to the maximum permissible

length in table 3.

Table. 3 - Max. length separate ducts

Table. 4 - Accessories

Connection to multiple flues

fig. 23 - Examples of connection to flues (

= Air /

= Fumes)

To connect the

ECONCEPT ST

boiler to a multiple flue or a single chimney with natural

draught, the flue or chimney must be expressly designed by professionally qualified tech-

nical personnel in conformity with the current regulations and be suitable for sealed

chamber units equipped with a fan.

In particular, chimneys and flues must have the following characteristics:

•

Be sized according to the method of calculation given in the current regulations.

•

Be fumetight, resistant to the fumes and heat and impermeable to condensate.

•

Have a round or quadrangular section, with vertical progression and no constrictions.

•

Have ducts that convey the hot fumes at a suitable distance or isolated from com-

bustible materials.

•

Be connected to only one unit per floor.

•

Be connected to a single type of unit (all or only forced draught units or all and only

natural draught units).

•

Have no mechanical suction devices in the main ducts.

•

Be at a lower pressure, along the entire length, in conditions of stationary operation.

•

Have at their base a collection chamber for solid materials or condensate, provided

with an airtight metal door.

Coaxial 60/100

Coaxial 80/125

Max. permissible length

5 m

15 m

Reduction factor 90° bend

1 m

0.5 m

Reduction factor 45° bend

0.5 m

0.25 m

C

13

C

13

C

33

C

33

C

33

C

13

Ø 100

Ø 60

120

142

Ø 80

Ø 127

120

147

Ø 100

Ø 60

041002X0

041006X0

041001X0

Separate ducts

Separate ducts

ECONCEPT ST 25

ECONCEPT ST 35

Max. permissible length

75 m

eq

55 m

eq

Losses in m

eq

Inlet

air

Fume exhaust

Vertical

Horizontal

Ø 80

PIPE

1 m M/F

1KWMA83W

1.0

1.6

2.0

BEND

45° M/F

1KWMA65W

1.2

1.8

90° M/F

1KWMA01W

1.5

2.0

PIPE SECTION

with test point

1KWMA70W

0.3

0.3

TERMINAL

air, wall

1KWMA85A

2.0

-

fumes, wall with antiwind

1KWMA86A

-

5.0

FLUE

Split air/fumes 80/80

1KWMA84U

-

12.0

C

53

C

33

C

53

B

23

C

13

041003X0

C

83

C

43

C

43