MOUNTING AND WIRING

CAUTIONS:

1. Ceramic insulators should nor be in or close to the flame.

2. Electrode assemblies should not be adjusted or disassem bled.

Electrodes should have a gap spacing of 0.125± 0.031 in

(3.12± 0.81 mm). If this spacing is not correct, the assembly must

be replaced. Electrodes are NOT field adjustable.

3. Exceeding the temperature limits can cause nuisance lockouts and

premature electrode failure.

4. Electrodes must be placed where they could not be exposed to the

appliance user in normal operation.

SEQUENCE OF OPERATION / FLAME

RECOVERY / SAFETY LOCKOUT

Power Up/Stand-By

• Upon applying power (24 VAC) to 24V terminal, the control will

reset, perform a self check routine, initiate full time flame sensing,

flash the diagnostic LED for up to four seconds, and enter the

thermostat scan state.

Heat Mode

• When a call for heat is received from the thermostat supplying 24

volts to TH/W, a pre-purge delay begins, then the gas valve is

energized and the sparks commence at both burners for the trial

for ignition period.

• When flame is detected during the trial for ignition, sparks are

shutoff immediately and the gas valve remains energized. The

thermostat and burner flame are constantly monitored to assure

the system continues to operate properly. When the thermostat

is satisfied and the demand for heat ends, the main valve is

de-energized immediately.

Failure to Light - Lockout

SINGLE TRIAL MODEL

Should either burner fail to light, or flame is not detected during the

trial for ignition period, the control will go into lockout and the valve

will be turned of immediately.

MULTI TRIAL MODEL

Should either burner fail to light, or flame is not detected during

the first trial for ignition period, the gas valve is de-energized

and the control goes through an interpurge delay before another

ignition attempt. The control will attempt two additional ignition

trials before going into lockout and the valve relay will be de-

energized immediately.

Recovery from lockout requires a manual reset by either resetting

the thermostat or removing 24 volts for a period of 5 seconds.

FLAME FAILURE- RE-IGNITION

If the established flame signal is lost from either burner while the

burners are operating, the control will respond within 0.8 seconds.

The HV spark will be energized for a trial for ignition period in an

attempt to relight the burners. If either burner does not light the

control will de-energize the gas valve. Multi-try models will make

two more attempts to relight the burners. If either burner does not

relight the control will go into lockout as noted above in “Failure

to light”. If flame is re-established, normal operation resumes.

Flame Fault

If at any time the main valve fails to close completely and main

tains a flame, the full time flame sense circuit will detect it and

flash an error code of 2.

CAUTION:

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

A functional checkout of a replacement control is recommended.

WARNING:

Operation outside specifications could result in failure of the

Fenwal product and other equipment with injury to people

and product.

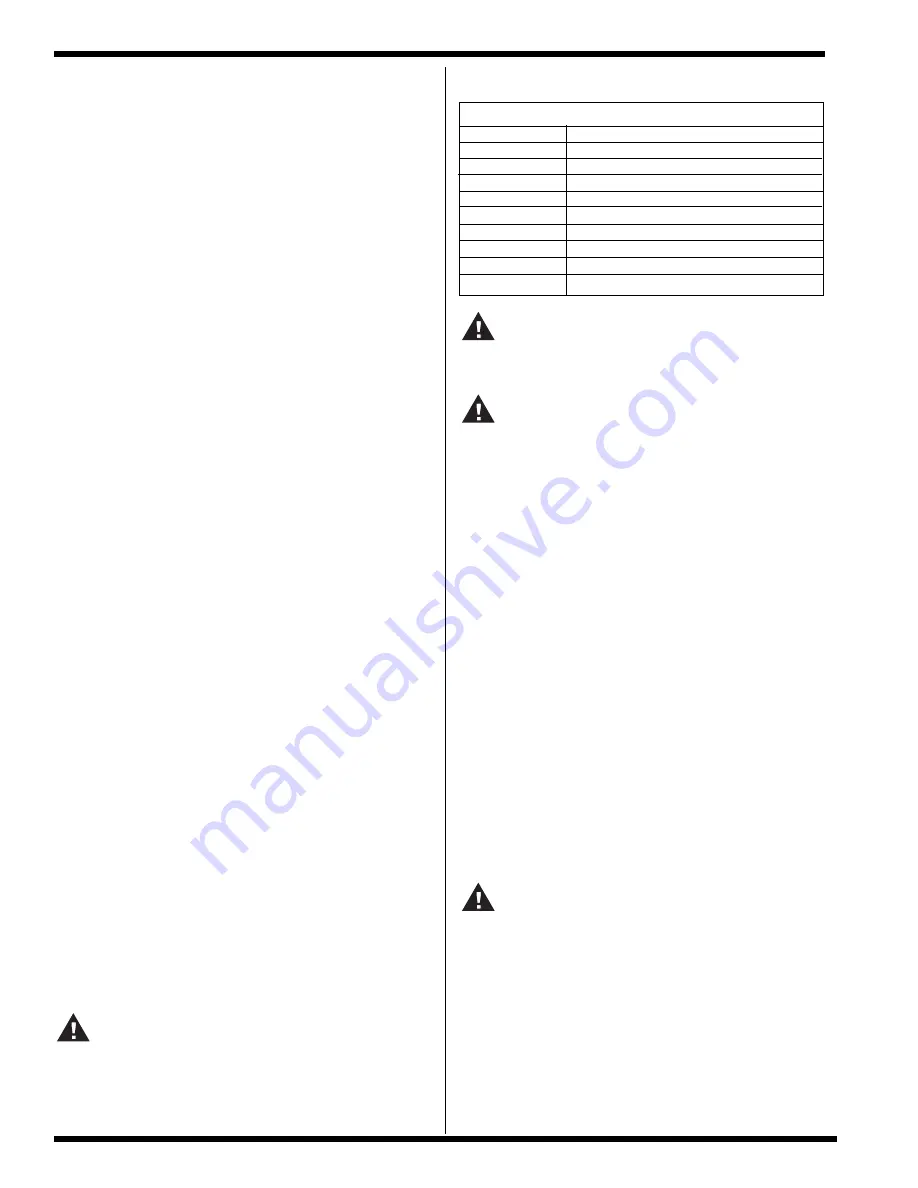

TERMINAL DESIGNATIONS

TH/W

THERMOSTAT INPUT

GND

SYSTEM GROUND

V1

VALVE POWER

V2

VALVE GROUND

NC

ALARM

S1

REMOTE FLAME SENSOR

S2

REMOTE FLAME SENSOR

FC1

FLAME CURRENT TEST PIN

FC2

FLAME CURRENT TEST PIN

24V

24 VAC INPUT (FULL TIME)

WARNING:

The Series 35-62 uses voltages of shock hazard potential. Wiring

and initial operation must be done by a qualified service technician.

The Series 35-62 is not position sensitive and can be mounted

vertically or horizontally. The control may be mounted on any

surface with #6 sheet metal screws.

All wiring must be done in accordance with both local and

national electrical code. The control must be secured in a area

that will experience a minimum of vibration and remain below the

maximum operating temperature of 160°F.

All connections should be made with UL approved 105°C rated

18 gauge, stranded,.054 thick insulated wire. Refer to wiring

diagram when connecting the Series 35-62 to other components

in the system.

PROPER ELECTRODE LOCATION

Proper location of the electrode assembly is important for

optimum system performance. It is recommended that electrode

assembly be mounted temporarily using clamps or other suitable

means so that the system can be checked before permanently

mounting the assembly. The electrode assembly should be

located so that the tips are inside the flame envelope and about

1/2 inch (1 cm) above the base of the flame. See Figure 3.

Page 2

Series 35-62, 24 VAC Dual Point DSI Control

www.fenwalcontrols.com

1-800-FENWAL-1