4

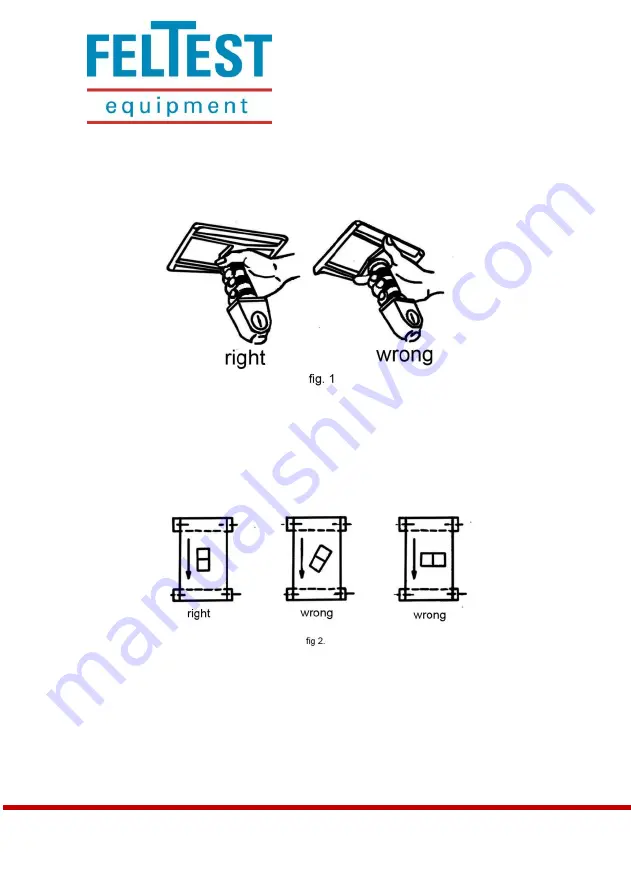

3. With the longer side of the frame oriented in the

machine running direction, press the instrument slowly

against the web until the pointer of the indicator stops.

4. Remove the instrument and read the dial.

5. Reset the pointer of the dial to the zero position and

perform the measurement at least once more to check

repeatability.

Содержание TensioMaster

Страница 1: ...Feltest TensioMaster Instruction manual ...