FELIX 3.0 - Quick start guide

Page 3 of 4

On

line

C

a

lib

ra

ti

on

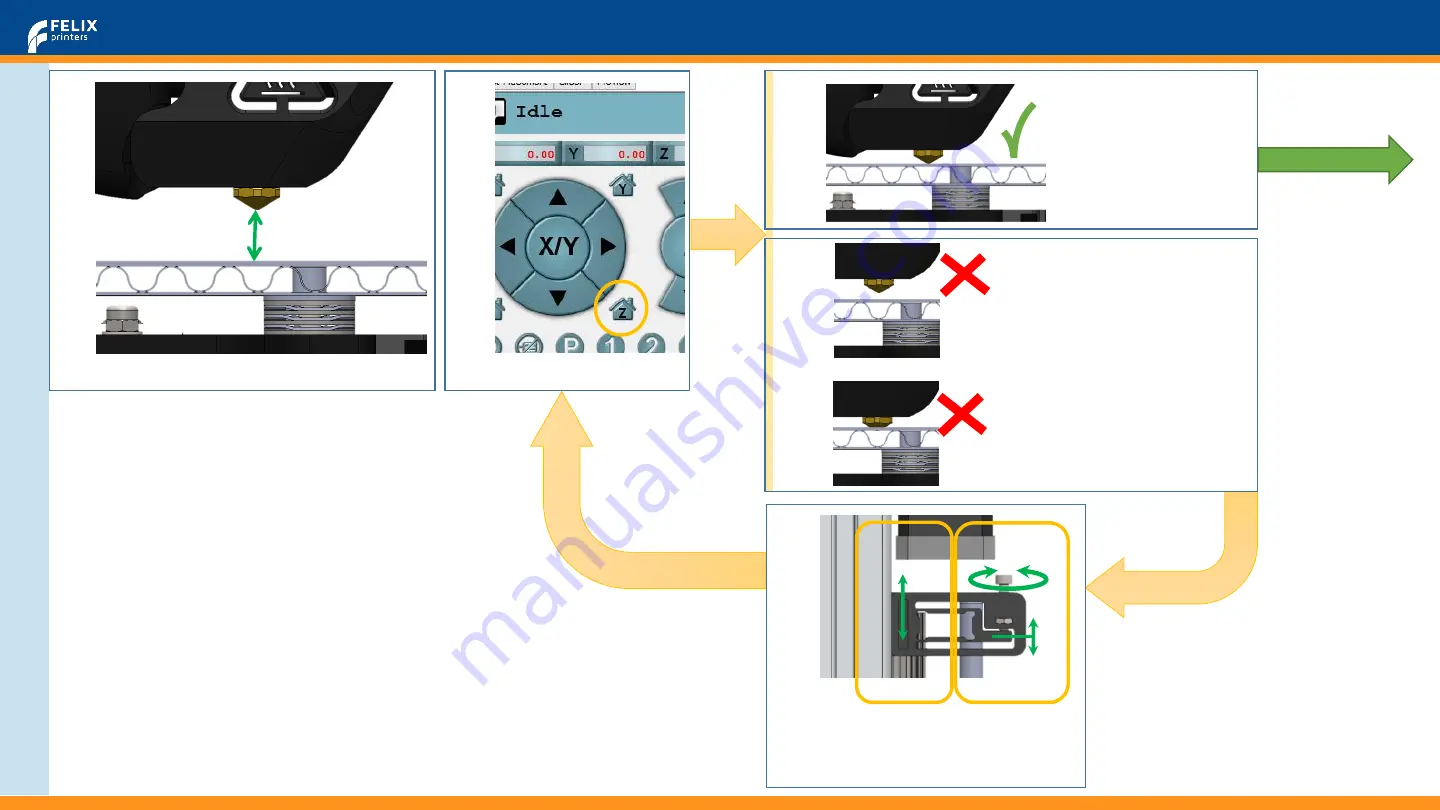

2.Turn screw for

fine adjustment

1. Move whole

bracket for rough

adjustment

No air gap

No contact

between nozzle

and table

Too far:

Big gap

Too close:

Nozzle hits table

Turn spindle by hand

to obtain a

minimum

distance

of

10mm

22

24b

23

26

24a

Calibration

Successful

Press

Home Z

NOTE:

This calibration step together with previous

calibration of table are very important for the

following reasons:

Prevents damage to printer

Ensures optimal adhesion of object to print bed.

NOTE:

Lowering the switching vane means

that the print bed will stop further

away from the nozzle tip.