37

5.1 Normal Cleaning

:

Positive Pressure Cleaning

Press the cleaning button, and then use sponge stick or soft fabric to wipe the surface

of the printhead.

Warning: Using the material other than sponge stick or soft fabric to wipe the

printhead may risk damaging nozzles.

5.2 Cleaning procedures for nozzle clogging

Ⅰ

.

Disconnect

the

tube

connector

for

the

tube

from

the

Subtank

to

the

printhead.

Wait

until

the

ink

finishes

dropping

almost,

and

then,

connect

the

tube

to

the

solvent

tube.

Press

both

of

the

flush

buttons

to

clean

the

printhead

with

solvent.

Stop

until

the

solvent

becomes

clear

nearly.

Ⅱ

.

Use

tube

cover

to

seal

the

ink

incoming

tube

for

the

printhead.

Use

fresh

wrap

to

cover

the

nozzle

surface.

Leave

it

for

12

hours.

Ⅲ

.

Take

the

fresh

wrap

off.

Disconnect

the

tube

cover

and

wait

until

the

solvent

is

removed

almost.

Connect

the

tube

to

the

subtank,

and

fill

the

printhead

with

ink.

The

condition

of

printhead

should

be

improved

after

performing

the

above

cleaning

procedures.

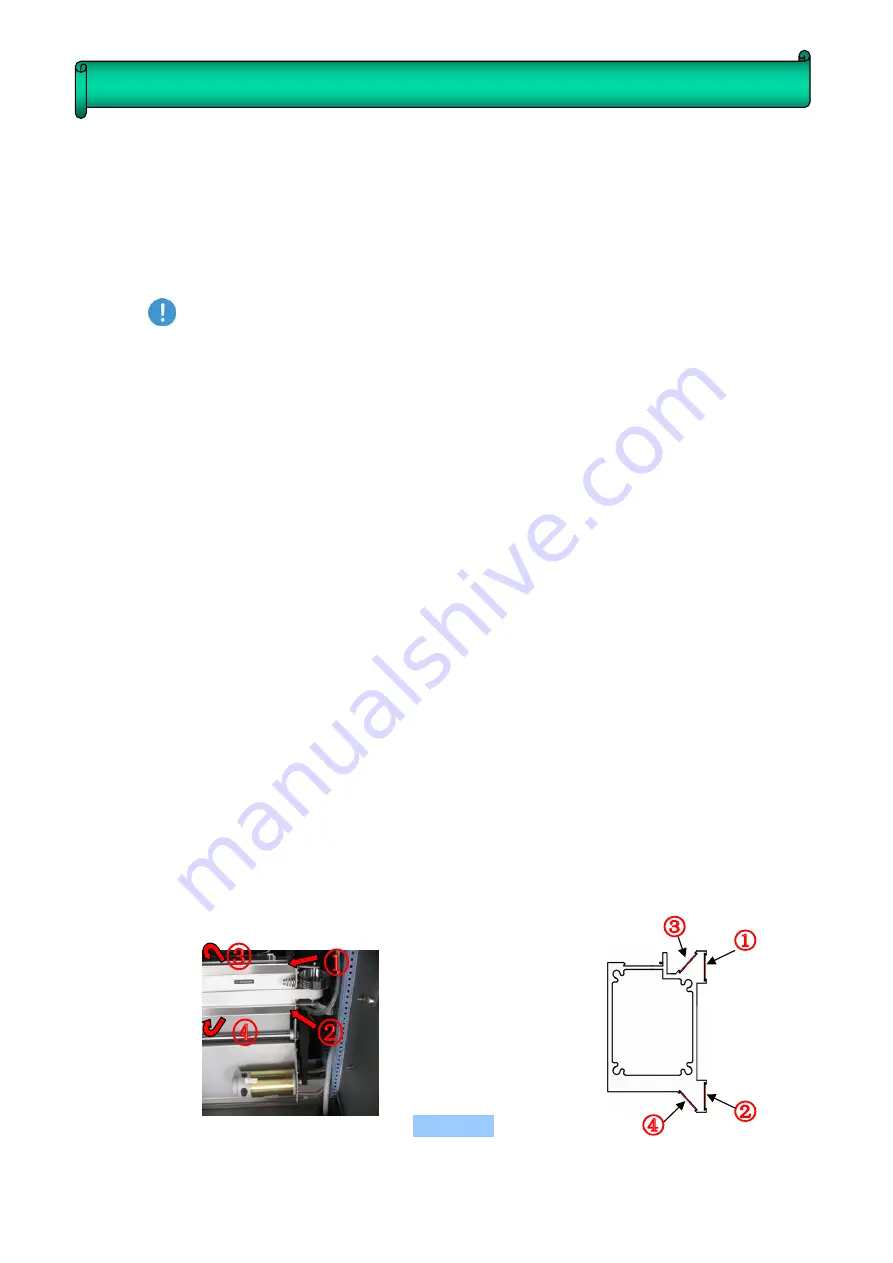

5.3

Carriage Bearing and Steel Rail Maintenance

Due

to

the

carriage

slides

on

four

steel

plates

and

eight

bearing,

clean

and

lubricate

four

steel

plates

with

grease

everyday.

Ⅰ

.

Wipe

a

thin

layer

of

grease

on

steel

plates

to

maintain

cleanliness

and

grease

everyday

before

and

after

usage.

Ⅱ

.

Be

aware

of

the

smoothness

of

the

carriage

bearing

Figure

5

‐

1

Chapter

5

Maintenance

Guide