-4-

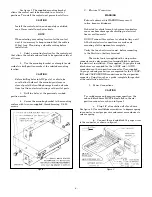

Figure 4.

1.

See figure 5. Remove and retain the two

screws which secure the lens. Carefully pull the lens

straight away from the light assembly.

CAUTION

Service life of lamp will be shortened if glass

is touched. If glass has been handled, clean

with a grease solvent.

2.

Remove the defective lamp by carefully

pulling it out of the socket. Install a new lamp by aligning

the pins on the lamp base with the holes in the socket, and

carefully pushing the lamp into the socket.

3.

Replace the lens using the previously removed

screws.

VI. SERVICE.

A.

General.

Servicing, other than cosmetic features, should be

performed by a qualified Federal Signal service center. If

the control unit is not working properly, disconnect all

electrical connections starting with the six-position power

connector. Remove the control unit from the mounting

bracket. Send the unit to the nearest authorized service

center or the Federal Signal service department.

Communication and shipments should be addressed to:

Service Department

Federal Signal Corporation

2645 Federal Signal Drive

University Park, IL 60466

1-800-433-9132

After servicing is complete, perform a test of all

functions to ensure the control unit is operating properly.

B.

Replacement Parts List.

Description

Part Number

Printed Circuit Board Assembly

2001135

Knob, Pushbutton

8573065

Knob, Slide Switch

8536C1041

Bezel, Slide Switch

8573060

Connector, Female, 6-Position

140325-04

Bracket, Mounting

8573070

Screw, Hex Head, Mounting

7011164B-08

Lockwasher, 1/4"

7075078

Chassis

8573068

Cover

8573066

Microprocessor

SM144100

Lamp, G.E. GH-22, 27-watt

8573007

Lens, Amber

8573001-02

simulates the light pattern being executed by the direc-

tional light.

A.

Slide Switch.

1.

LEFT (Position 1).

In this position, the driver side unit produces

a left arrow flashing pattern, instructing traffic to move

left.

2.

CENTER OUT (Position 2).

In this position, a center out flashing pattern

is produced on both the driver and passenger side units,

instructing traffic to move around either side of the vehicle.

3.

RIGHT (Position 3).

In this position, the passenger side unit

produces a right arrow flashing pattern, instructing traffic

to move right.

B.

WARN switch.

When this switch is pressed, an alternating

pattern is produced. The driver side unit activates alter-

nately with the passenger side unit. This pattern will

override any of the slide switch functions.

V.

MAINTENANCE.

A.

General.

WARNING

Crazing (cracking) of lenses will cause reduced

effectiveness of the light. Do not use cleaning

agents (which will cause crazing) such as strong

detergents, solvents, or petroleum products. If

crazing of lenses does occur, reliability of light

for emergency signalling purposes may be re-

duced until lenses are replaced.

Ordinary cleaning of the plastic lenses can be

accomplished by using mild soap and a soft rag. Should fine

scratches or a haze appear on a lens, they can ordinarily be

removed with a non-abrasive, high quality, one-step,

automotive paste cleaner/wax and a soft cloth.

B.

Lamp Replacement.

CAUTION

Use of higher wattage lamps can result in damage

to the colored lenses.

Figure 5.