FCI WATERMAKERS, INC.

127

Troubleshooting

One of the most important steps in a high pressure system is to establish a

regular maintenance program. This will vary slightly with each system and

is determined by various elements such as the duty cycle, the liquid being

pumped, the actual specifications vs. rated specifications of the pump, the

ambient conditions, the inlet conditions and the accessories in the system. A

careful review of the necessary inlet conditions and protection devices required

before the system is installed will eliminate many potential problems.

These pumps are very easy pumps to service and require far less frequent service

than most pumps. Typically, only common tools are required, making in‑field service

convenient, however, there are a few custom tools special to certain models that do

simplify the process.

will assist in troubleshooting the high pressure pump.

HIGH PRESSURE PUMP TROUBLESHOOTING

GUIDE

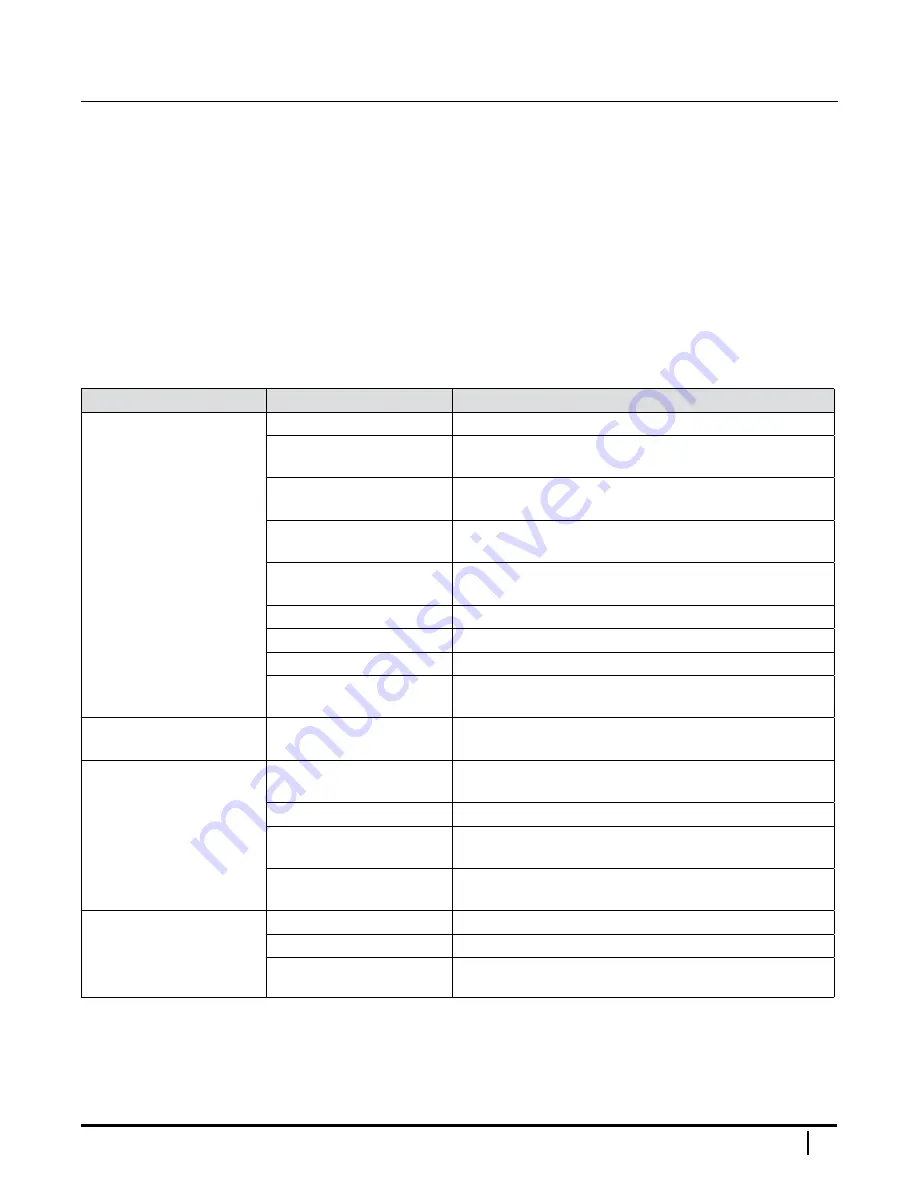

Table 4: High Pressure Pump Troubleshooting Guide

Problem

Probable Cause

Solution

LOW PRESSURE

Air leak in inlet plumbing.

Tighten fittings and hoses. Use PTFE liquid or tape.

Pressure gauge inoperative

or not registering accurately.

Check with new gauge. Replace worn or damaged gauge.

Inlet suction strainer (filter)

clogged or improperly sized.

Clean/adjust relief valve. Replace worn seats/valves and o-rings.

Abrasives in pumped liquid.

Clean filter. Use adequate size filter. Check

more frequently. Install proper filter.

Leaky discharge hose.

Replace discharge hose with

proper rating for system.

Inadequate liquid supply.

Pressurize inlet.

Severe cavitation.

Check inlet conditions.

Worn seals.

Install new seal kit. Increase frequency of service

Worn or dirty inlet/

discharge valves.

Clean inlet/discharge valves or install new valve kit.

PULSATION

Foreign material trapped

in inlet/discharge valves.

Clean inlet/discharge valves or install new valve kit..

WATER LEAK

• Under the manifold

•

Into the crankcase

Worn V-Packings or

Lo-Pressure Seals.

Install new seal kit. Increase frequency of service.

Worn adapter o-rings.

Install new o-rings.

Humid air condensing into

water inside the crankcase.

Install oil cap protector. Change oil every 3 months or 500 hours.

Excessive wear to seals

and V-Packings.

Install new seal kit. Increase frequency of service.

KNOCKING NOISE

•

Inlet supply

• Bearing

•

Pulley

Inadequate inlet liquid supply. Check liquid supply. Increase line size, pressurize.

Broken or worn bearing.

Replace bearing.

Loose pulley on crankshaft

Check key and tighten set screw.

Содержание MAX-Q+

Страница 1: ......

Страница 2: ......

Страница 16: ......

Страница 22: ......

Страница 26: ......

Страница 31: ......

Страница 32: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 45: ......

Страница 46: ......

Страница 47: ......

Страница 50: ......

Страница 51: ......

Страница 52: ......

Страница 53: ......

Страница 54: ......

Страница 55: ......

Страница 56: ......

Страница 57: ......

Страница 58: ......

Страница 62: ......

Страница 72: ......

Страница 87: ......

Страница 108: ......

Страница 113: ......

Страница 115: ......

Страница 117: ......

Страница 122: ......

Страница 130: ......

Страница 136: ......

Страница 137: ......

Страница 138: ......

Страница 139: ......

Страница 140: ......

Страница 141: ......

Страница 142: ......

Страница 143: ......

Страница 144: ......

Страница 145: ......

Страница 146: ......

Страница 147: ......

Страница 148: ......

Страница 149: ......

Страница 150: ......

Страница 151: ......

Страница 152: ......

Страница 153: ......

Страница 154: ......

Страница 155: ......

Страница 156: ......

Страница 157: ......

Страница 158: ......

Страница 159: ......

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 163: ......

Страница 164: ......

Страница 165: ......

Страница 166: ......

Страница 167: ......

Страница 169: ......