Page

6

/

37

Detection Sub-assembly / Electronic Enclosure

The detection sub-assembly is housed in a flame-proof box which permits the use of the

flowmeter in electrically classified areas (UL/cUL Class 1 Div 1 Group C & D; ATEX/IECEx II1G – IIC

T6). The electronic enclosure integrates the following elements:

•

A pick up coil housed in the bottom of each boss and kept in position by means of a ring

•

A coil/pre-amplifier connection cable

•

An optional pre-amplifier which allows operators to significantly increase the maximum

distance between the flowmeter and the electronic display and/or flow computer (up to

5,000 meters/16,000 ft)

Flow Conditioning

According to API MPMS Chapter 5.3 and ISO 2715, “The performance of turbine meters is

affected by swirl and non-uniform velocity profiles that are induced by upstream and downstream

piping configurations, valves, strainers, pumps, fittings, joint misalignment, protruding gaskets,

welding projections, or other obstructions. Flow conditioning shall be used to overcome the

adverse effects of swirl and non-uniform velocity profiles on turbine meter performance.”

Faure Herman can supply the flow conditioning assembly which integrates upstream piping,

flow conditioning element (plate, straightening vanes, etc.) and downstream piping (to be utilized

at time of meter calibration).

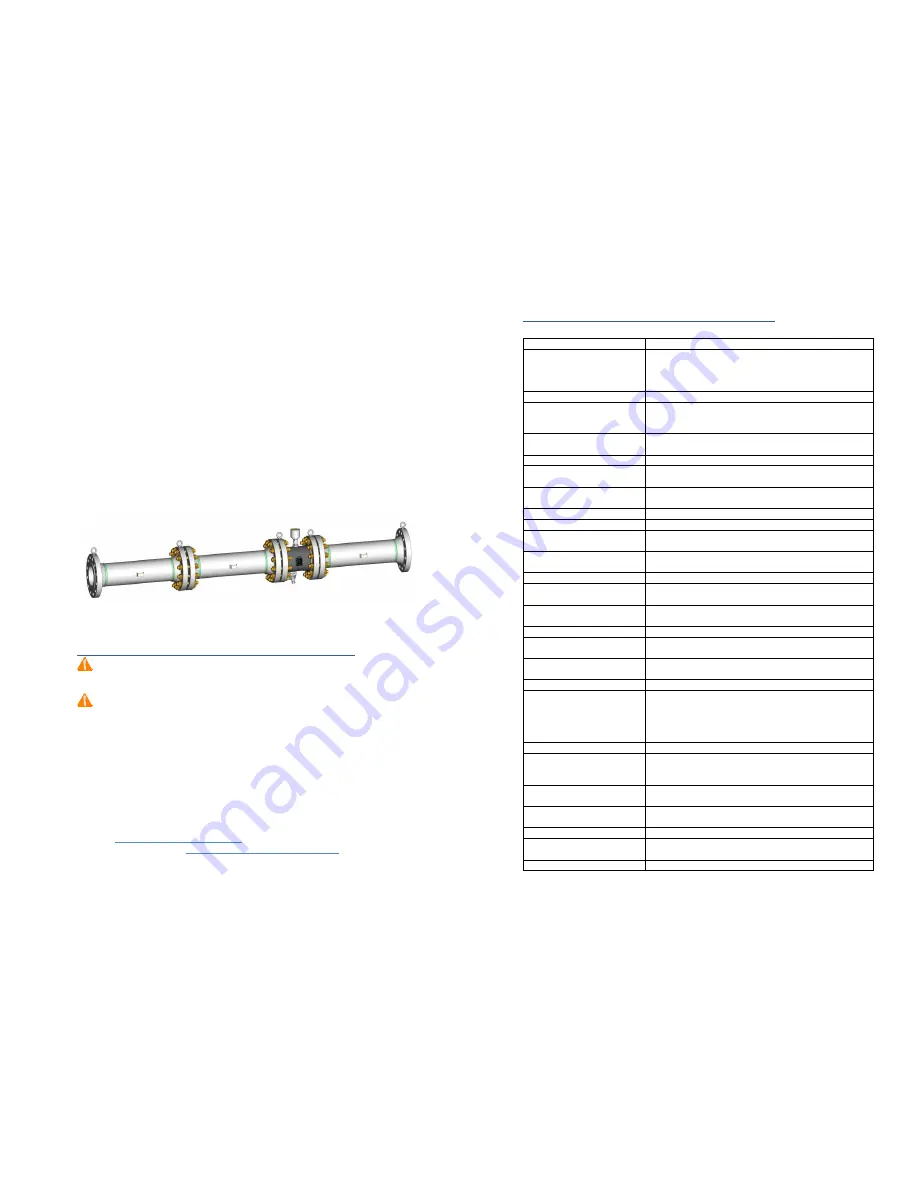

Figure 4. Complete Meter run with upstream/downstream spool pieces and flow conditioner

Chapter 3: Equipment Receipt, Storage and Handling

Upon receipt of the TZN turbine meter, inspect the packing case for any shipping damage. The

meter must be carefully removed from the packing case and inspected for potential damage or

missing parts (including documentation)

Before installation, the unit should remain stored in its original packing, protected against

adverse weather conditions, and maintained at temperatures between -20 /+70 °C (-4 /+158 °F).

If the meter isn’t installed within a month, FH recommends maintaining the metering assembly

in an inerted atmosphere (nitrogen) or fluid filled state (light hydrocarbons). Please check

applicable regulation to ensure that all calibration requirements have been met.

Prior to installing the TZN, visually inspect the turbine meter; pay particular attention to name

plate (check for serial number, process conditions, direction of flow …), flange rating and general

conditions.

Should the product be damaged or documents missing, please contact the Faure Herman

Worldwide Customer Support & Service via phone, email or website:

Hotlines:

+1 (713) 597 4827 (North America)

+33 (0)2 43 60 28 55

Email:

Online Assistance website:

https://faureherman.zendesk.com/hc/en-us

Page

35

/

37

Risk analysis according to Directive 2014/68/EU

Suitable resistance

Requirements

Excess temperature and

pressure

Temperatures and pressure limits should be considered during

the design phase.

The limitations are indicated on the equipment; the user is

responsible to set up equipment properly.

Wind / Snow influence

NA: Without influence considering the small surface areas

Earthquake

The equipment is not intended for use in a seismic zone. If

operated as such, it is the responsibility of the user to provide

adapted devices.

Support, binding and piping

reaction

The equipment is designed to be joined to other piping; it

does not have its own supports.

Thermal fatigue

Design choice of materials follows ASME B31.3.

Mechanical fatigue

This is metrological equipment; it is the user’s responsibility to

install properly to avoid mechanical stress.

Vibration

This is metrological equipment; it is the user’s responsibility to

install away from sources of vibration.

Handling and operation

Comments

Closing and opening

NA: the equipment does not have an aperture or closure.

Dangerous emissions from

valves

NA: the equipment does not have a valve.

Access to the inside

NA: the equipment does not have access (inspection hatch,

manhole).

Surface temperature

The user is responsible for indication of hot surfaces.

Decomposition of unstable fluid

NA: The equipment is used for the transfer of fluid not

storage.

Handling

Equipment > 30kg is equipped with lifting rings for safe

handling.

Draining and venting

Comments

Pressure wave

This is sensitive metrological equipment; it is the user’s

responsibility to install properly to avoid pressure waves.

Vacuum collapse

Minimal service pressure of 0 bar.g indicated on the plate.

This equipment is not designed to work under vacuum.

Corrosion and chemical attack

Comments

Uniformly generalized

Consideration of corrosion thickness.

Choose proper materials and application of painting systems

adapted to the environment.

It remains under user responsibility to periodically check the

condition of its installation.

Selective

Choose proper materials

Galvanic

Choose proper materials and review compatibility of

materials. It is the user’s responsibility to set up adapted

devices, grounding straps, cathodic protection…

By differential aeration

Choose proper materials – Maintain the equipment full of

fluid.

By puncture, crevice,

intergranular

Choose proper materials. Review compliance with NACE

MR0175 requirements if applicable.

Ammonia

Choose proper materials

Under stress

Choose proper materials. Review compliance with NACE

MR0175 requirements if applicable.

Wear

Comments