9

8. Testing Procedures (continued)

Seat Leakage Test:

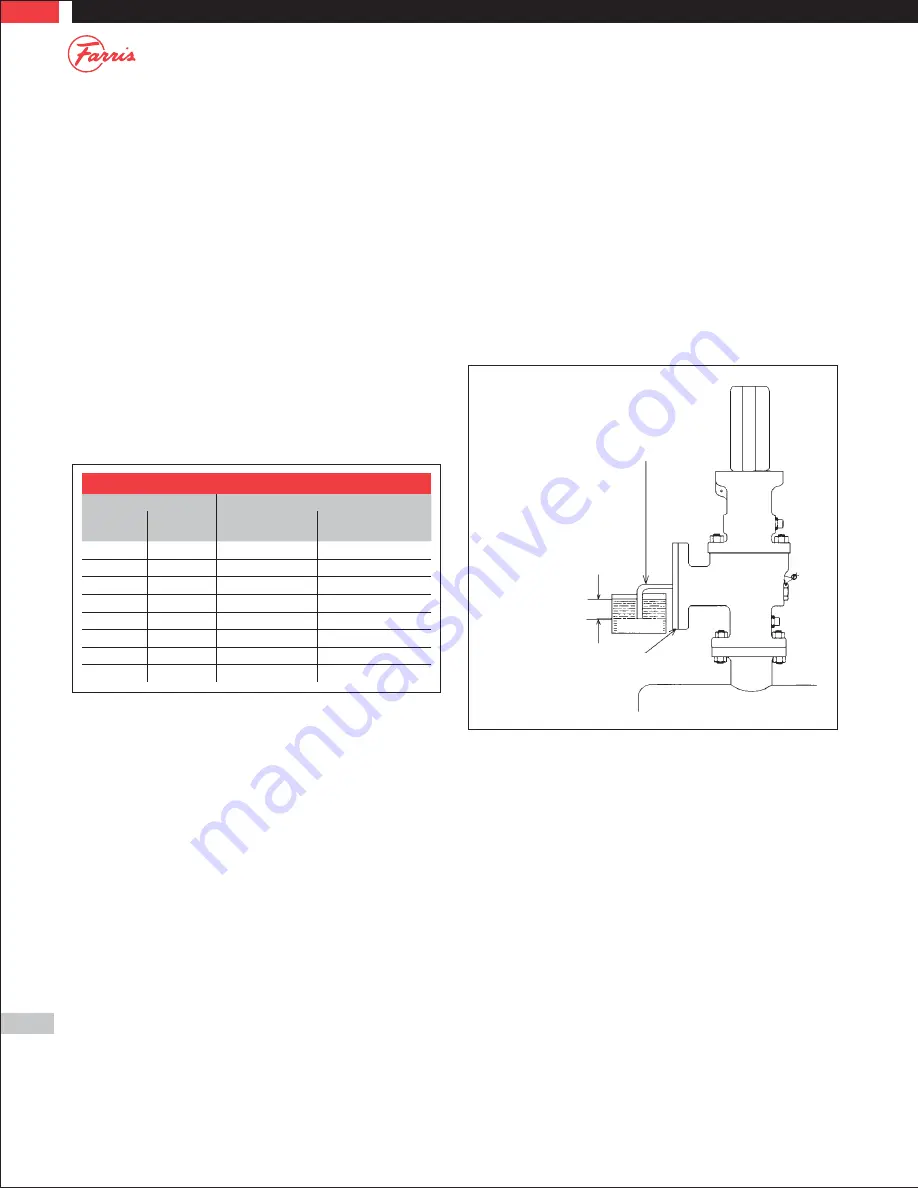

1. Next perform a seat leakage test. With the valve mounted on the test

stand, attach a blind flange test fixture as shown in Figure 6 (air, gas, &

vapor service valves only). For steam and water seat leakage testing,

see paragraphs 4 and 5.

2. For metal and soft seated valves the pressure is held at 90% of cold

differential test pressure when the CDTP is greater than 50 psig. For

CDTP 50 psig and below, the pressure should be held 5 psig below the

CDTP.

3. Bring the pressure up and hold it for one minute for valves up to 2" inlet

size, 2 minutes for valves from 2 1/2" to 4" inlet size, and 5 minutes for

valves with inlet sizes 6" and larger. Then count the number of bubbles

for one minute. The acceptance criteria for metal seat valves are per the

following table. For O ring and soft seat valves, there should be no

leakage (zero bubbles per minute).

Table 3

Seat Tightness: Air, Gas & Vapor Service

Set Pressure

Leakage Rate in Bubbles Per Minute

psig

barg

Orifice Size ≤ 0.307

Sq. In (200 mm

2

)

Orifice Size < 0.307

Sq. In (200 mm

2

)

15 to 1000

1.03 to 68.9

40

20

1500

103

60

30

2000

138

80

40

2500

172

100

50

3000

207

100

60

4000

276

100

80

5000

345

100

100

6000

413

100

100

4. Steam: Test pressure per paragraph 2 shall be applied for 3 minutes

before the seat tightness test. The valve should be observed for leakage

for at least one minute. There should be no visible sign of leakage at the

valve outlet when viewed against a black background.

Where the Code allows ASME Section VIII steam valves to be tested on air,

seat leakage may be verified using the procedure for air, gas, and vapor

service valves as listed in paragraphs 1 to 3.

5. Water: Liquid valves are tested on water. Test pressures per paragraph

2 should be applied for a period of two minutes. There should be no

visible sign of leakage.

Note: When performing the seat leakage test on valves with open levers, a

plain screwed test cap must be used. This will prevent the venting of the

test pressure through the top of the bonnet.

Tube 5/16" (7.9 millimeters)

OD x 0.035 inch

(0.89 millimeter) Wall

Note: The cover plate should be fitted with a

suitable device to relieve body pressure in case

of accidental popping of the valve.

1/2" (12.7 millimeters)

WATER

AIR RECEIVER

Figure 6

Содержание Curtiss-Wright 1890 Series

Страница 1: ...Technical Manual 1098T R1 Pressure Relief Valve Maintenance Manual ...

Страница 11: ...10 ...