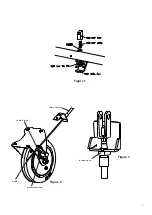

3.9 BRAKE MECHANISM

Refer to

Figures 2 and 3

.

(Page 7)

To adjust tension on brake cable:

Remove lower control panel below brake handle.

Use nut on underside to adjust to required tension.

Replace in reverse order.

If further adjustment is required:

Loosen brake cable terminal at castor.

Pull cable tight.

Re-tighten cable terminal.

Replace in reverse order.

To replace cable:

Cut off cable nipple.

Loosen cable terminal.

Pull cable free from sheath.

Replace in reverse order.

3.10 CASTORS

Note

: This unit is heavy.

Note

: Refer to Section 1.1 for nett weights. Take due care

when replacing castors. Unit may be jacked up or lifted

upon blocks to allow safe removal of castor(s).

Alternatively, an empty trolley may be laid on its back

provided appropriate lifting assistance is available to do

this in a safe and controlled manner.

Note

: Always replace castor with correct specification

variant for the given position.

To remove Castor

: Undo fixings on underside of trolley

to remove. Refit in reverse order.

To remove Castor with Brake: Loosen tension of cable

before release from castor brake mechanism. Replace in

reverse order.

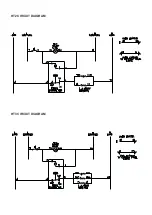

To set brake tension, tighten turnbuckle to top and relase

by a half turn. Lock in place with nut. Regrease mecha-

nism at handle bar and castor. When trolley is resting on

all castors, ensures brake operates smoothly. It should

not be possible to move trolley when hand levers are re-

leased. Adjust screw link if necessary. Re-fit side panel

when satisfied brake operates correctly.

3.11 DOOR

To remove door, undo top door hinge fixings. Swing door

open and lift off bottom hinge.

To remove door catch roller bar assembly, undo locknut

to remove securing pin and roller.

Re-fit in reverse order. Check door operates as required.

3.12 DOOR with DOOR SEAL

Remove door as detailed in Section 3.11.

To remove door seal, undo fixings on inner door panel.

When refitting seal, start at bottom of door. Fit in stages

while securing inner panel. Make triangular cuts into seal

flange to form bends at corners. Apply sealant at

seal joint.

3.13 CHAMBER DOOR SEAL

Use a Ø4.5mm drill to remove aluminium rivets.

Re-use metal strips and rivet replacement seal to

chamber.

3.14 DUMMY SOCKET

Loosen mains power cable arrester. Remove side panel

fixings as Section 3.1 and open panel. Take care not to

put strain on power cable.

To remove socket, depress assembly fixing tabs and

withdraw through stiffening plate and panel.

Re-fit in reverse order, making sure stiffening plate is

fitted. Ensure cable arrest is effective.

SECTION 4 - SPARES

When ordering spare parts, always quote unit type and

serial number. This information can be found on

appliance data plate located upon appliance rear panel.

6