20

ENGLISH

ENGLISH

1)

Assemble the limit sensor centering the plate with respect to

the support threaded pins (Fig.26).

2)

Power up automation.

3)

Manually take the gate to opening position, leaving at least

2 cm from the travel limit mechanical stop.

4)

Allow the plate to slide over the rack in opening direction. As

soon as the FCA LED on the 844 T card goes off, move the plate

forward by about 45 mm and secure it to the rack by

tightening the screws.

5)

Manually take the gate to closing position, leave a distance

of about 2 cm from the travel limit stop mechanism.

6)

Allow the plate to slide over the rack in closing direction. As

soon as the FCC LED on the 844 T card goes off, move the

plate forward by about 45 mm and secure it to the rack by

tightening the screws.

7)

Re-lock the system (see paragraph 8).

8)

Command a complete gate cycle to check if the limit sensors

are tripping correctly.

N.B.: If the limit sensors are reversed (e.g. if the FCC LED goes

off when the gate is open), change over the cables con-

nected to the FCA and FCC inputs.

Notes on plate positioning

•

The distance between limit sensors and plates must be < 5mm

(Fig.11).

•

To avoid damaging the operator and/or interrupting opera-

tion, leave a distance of least 2 cm from the travel limit

mechanical stops.

5.7. ADJUSTING TRANSMITTED TORQUE

The 844 MC-T automation has an anti-crushing mechanical

clutch which (according to adjustment) limits the thrust of the

gate if it meets an obstacle.

After the obstacle is removed, the gate restarts moving either until

it reaches the limit sensor or when safety time has elapsed.

We advise you to set the torque limiter to conform to relevant

current laws.

Procedure for setting the tripping threshold of the anti-crushing

system:

1)

Turn off power to the automation.

2)

Remove the hole guard and fully unscrew the cover of the

clutch adjustment screw as shown in Fig.27.

(1) OPEN B input commands partial opening.

(2) With pre-flashing selected, movement begins after 5 sec.

(3) If the pulse is sent during pre-flashing, counting is restarted.

(4) OPEN B input commands closing.

(5) Push-button must be kept pressed to activate gate movement. When the

push-button is released, the gate stops.

5.4. FAULT CONDITIONS

The following conditions cause certain effects to normal operation

of automation:

a

microprocessor error

b

safety electronic timing tripped (operation is interrupted if

continuous work time exceeds 255 sec. ).

c

limit sensors disconnected (or both engaged)

• Conditions

a

and

b

cause automation to stop.

• Condition

c

causes an alarm situation disabling any activity:

Normal operation can be restored only after eliminating the

alarm cause and pressing the RESET push-button (or turning off

power supply momentarily).

To have this condition signalled, the warning light must be

connected: the alarm is signalled by very rapidly flashing light

(0.25 sec).

5.5. ROTATION DIRECTION CHECK

1)

Release the operator, take it manually to mid-travel and re-

lock it (see par. 8).

2)

Power up the system and then press the RESET push-button.

3)

Give an Open command to the operator, check if the gate

moves in opening direction and then press the RESET push-

button to stop the leaf moving.

4)

If rotation direction is incorrect, change over wiring of cables

T1 and T3 of the electric motor.

5.6. POSITIONING TRAVEL LIMIT PLATES

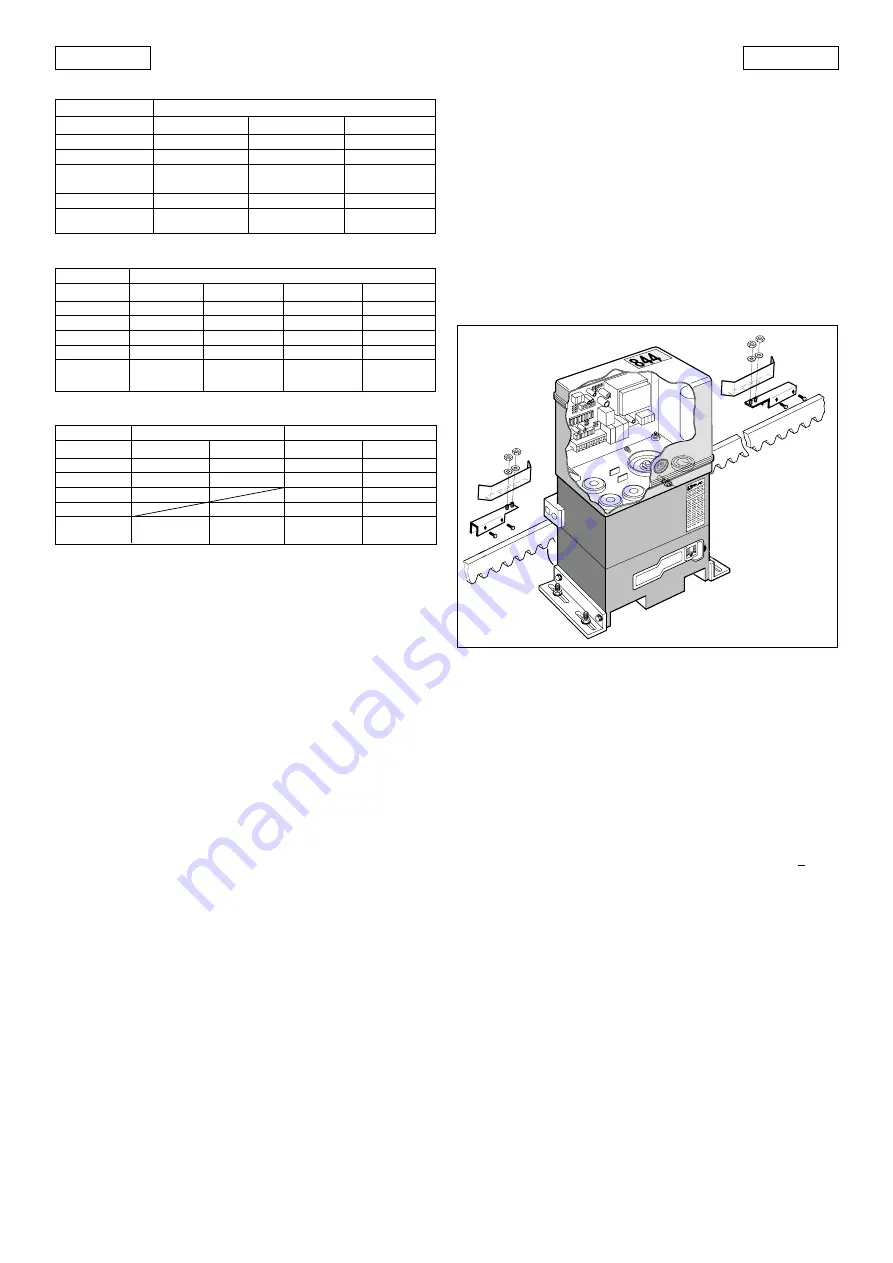

The 844 MT-C operator has inductive limit sensors (Fig.1 ref.3)

which, when they detect the movement of a plate secured to

the upper part of the rack, command gate movement to stop.

Procedure for correct positioning of the two supplied plates:

Fig. 26

TABLE 12

LOGIC C (DEADMAN)

TABLE 10

LOGIC E2 (SEMI-AUTOMATIC PLUS)

SAFETY DEVICES

no effect

no effect

stops and reverses

at disengagement (2)

no effect

no effect

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN A - OPEN B (1)

opens (2)

re-closes (2)

reverses motion

stops

re-closes (when safety devices

engaged, it re-opens) (2)

STOP

no effect

no effect

stops

stops

no effect

PULSES

LOGIC E2

TABLE 11

LOGIC B (SEMI-AUTOMATIC)

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

LOGIC B

PULSES

OPEN A

opens ( (2)

no effect

no effect

no effect

completes

opening (2)

OPEN B (4)

no effect

closes(2)

no effect

no effect

completes

closing (2)

STOP

no effect

no effect

stops movement

stops movement

no effect

SAFETY DEVICES

no effect

prevents closing

stops movement

no effect

prevents closing

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

LOGIC C

OPEN A (5)

opens

no effect

no effect

completes

opening

OPEN B (4 e 5)

no effect

closes

no effect

completes

closing

SAFETY DEVICES

no effect

prevents closing

stops movement

no effect

prevents

closing

STOP

no effect

no effect

stops movement

stops movement

no effect

CONTROLS HELD DOWN CONTINUOUSLY

PULSES