8

ENGLISH

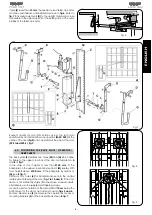

8. MAINTENANCE

When performing maintenance always check that the by-pass

screws are set correctly, that the up-and-over door is balanced

and that the safety devices operate correctly.

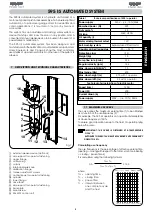

8.. TOPPING UP WITH OIL

Check periodically the quantity of oil inside the tank.

For medium/low use frequencies a yearly check is sufficient; for

more severe operation it is advisable to check every 6 months.

The oil level must not be lower than the index line.

To top up, unscrew the filler cap (Fig. 1 ref. 4) and pour in oil up

to the correct level.

Use exclusively FAAC HP OIL.

8.2. BLEEDING AIR FROM HYDRAULIC CIRCUIT

If the door moves in an irregular manner, this may be due to the

presence of air in the hydraulic circuit.

If it is necessary to bleed the air, proceed as follows:

1. Check that the breather screws have been removed

(Fig. 1 ref. 15).

2. Disassemble the lateral drive shafts from the operator.

3. Set an operating time of about 1 minute on the electronic

control unit.

4. Activate the operator electrically so that it turns to the

end of its travel in both directions of rotation.

5. Repeat this operation several times if necessary.

6. Follow the installation instructions to reassemble.

9.

REPAIRS

For repairs, contact an authorised FAAC Service Centre.

Содержание 595

Страница 1: ...595...