Maintenance

1.

Stop engine and wait for all moving parts to stop.

Engage parking brake. Remove key or spark plug

wire(s).

2.

With PTO engaged (lever pulled up, adjust the

linkage length to where the lower end of the

bellcrank just clears the axle support gusset (see

Figure 12). Make sure the assist arm is against the

rear assist arm stop on the deck (see Figure 13).

Push the lever down to the disengaged position.

The assist arm should contact the front assist arm

stop on the deck. If it does not contact, readjust

so that the bellcrank is closer to the gusset.

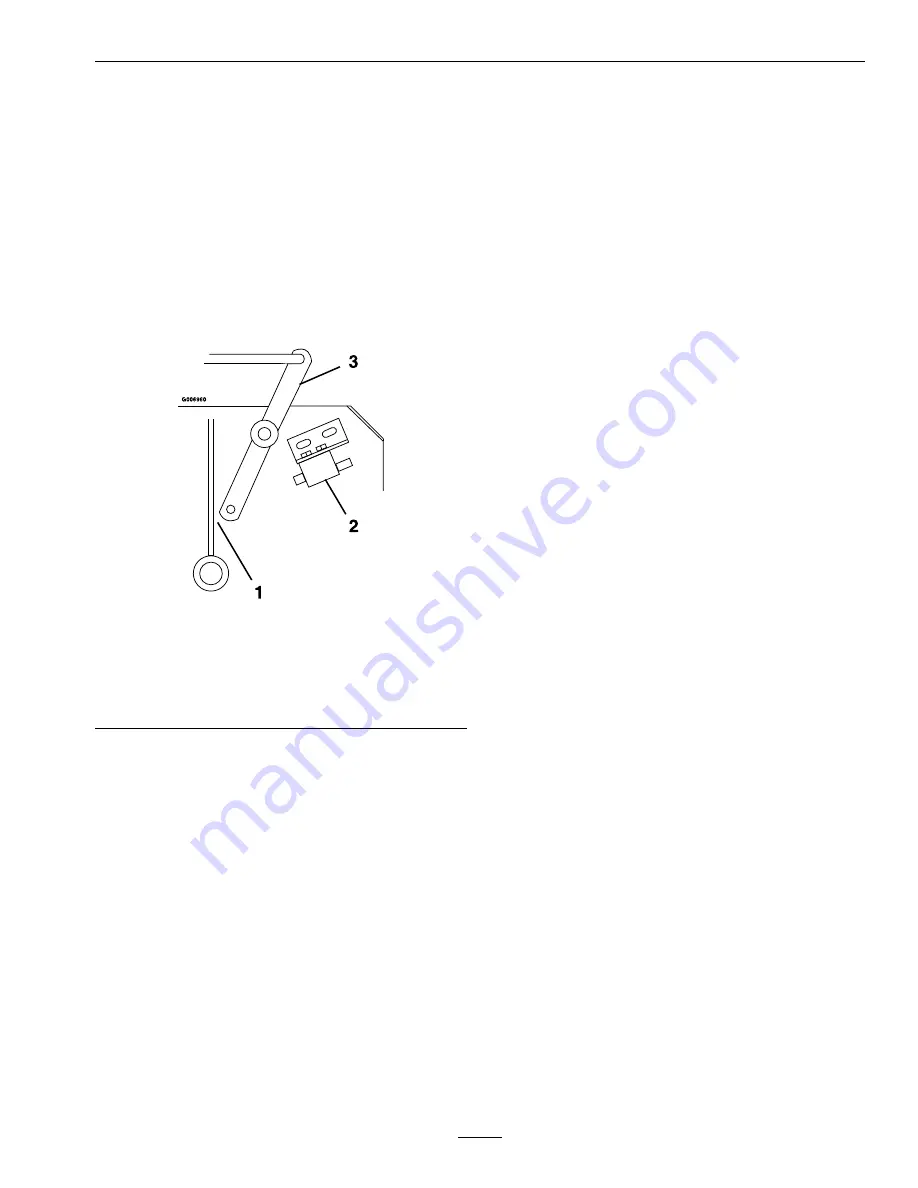

g006960

Figure 12

1.

The bellcrank just clears the gusset with the PTO

engaged

2.

PTO Safety Switch (located beneath the engine deck)

3.

Bellcrank

PTO Safety Switch

Adjustment

1.

Stop engine and wait for all moving parts to stop.

Engage parking brake. Remove key or spark plug

wire(s).

2.

With PTO disengaged and assist arm against the

front assist arm stop, adjust the blade safety switch

mounting bracket (if needed) until the bellcrank

depresses the plunger by 1/4 inch (.64 cm).

3.

Be sure the bellcrank Does Not touch the switch

body or damage to the switch could occur.

4.

Retighten switch mounting bracket.

Engine to Mower Deck Belt

Adjustment

1.

Stop engine and wait for all moving parts to stop.

Engage parking brake. Remove key or spark plug

wire(s).

2.

Engage PTO.

3.

Check belt guides under rear engine and front

mower deck to see that they are properly set (see

Belt Guide Adjustment

section for instructions).

4.

Belt must be tight enough so it does not slip during

heavy loads while cutting grass. Over-tensioning

will reduce belt and spindle bearing life. To adjust

belt tension, loosen the 5/16 inch whizlock nut

on turnbuckle and rotate the turn buckle; rotate

turnbuckle toward rear of mower to tighten, and

toward front of mower to loosen belt tension (see

Figure 13).

For 48 inch Decks: If there is no adjustment left

in the turnbuckle and the belt is still loose, the rear

idler pulley can be repositioned in the front hole

(see Figure 13). The belt guide located next to the

pulley must also be repositioned in the front hole

when the pulley is moved. The turnbuckle will

need to be readjusted.

Check belt tension after the first hour of operation

and at least twice during the first 24 hours of

operation. Adjust as necessary.

Note:

After readjusting the belt tension check the

belt guide adjustment as stated in the

Belt Guide

Adjustment

and

Blade Brake Adjustment

sections.

35

Содержание VIKING 346

Страница 1: ...VIKING For Serial Nos 408 644 346 Higher Part No 4505 182 Rev A ...

Страница 45: ...Schematics g010189 45 ...

Страница 47: ...47 ...