Rectifying faults

Vent coolant circuit

46

099-005593-EW501

10.01.2022

7.4

Vent coolant circuit

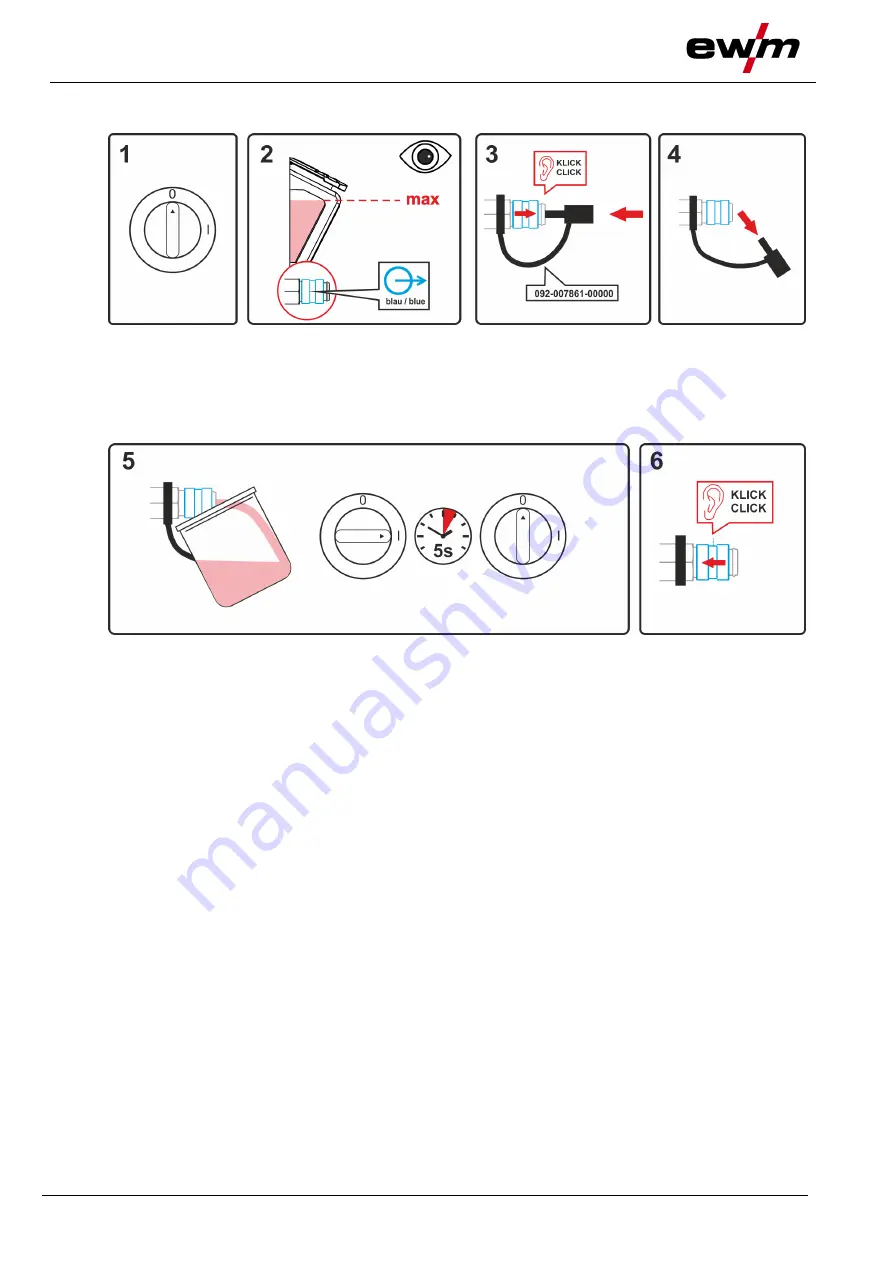

Figure 7-1

• Switch off the machine and fill the coolant tank to the maximum level.

• Unlock the quick-connect coupling with a suitable tool (connection open).

To vent the cooling system always use the blue coolant connection, which is located as deep as

possible inside the system (close to the coolant tank)!

Figure 7-2

• Position a suitable collection container for collecting the escaping coolant at the quick-connect coup-

ling and switch on the machine for approx. 5s.

• Lock the quick-connect coupling by pushing back the locking ring.