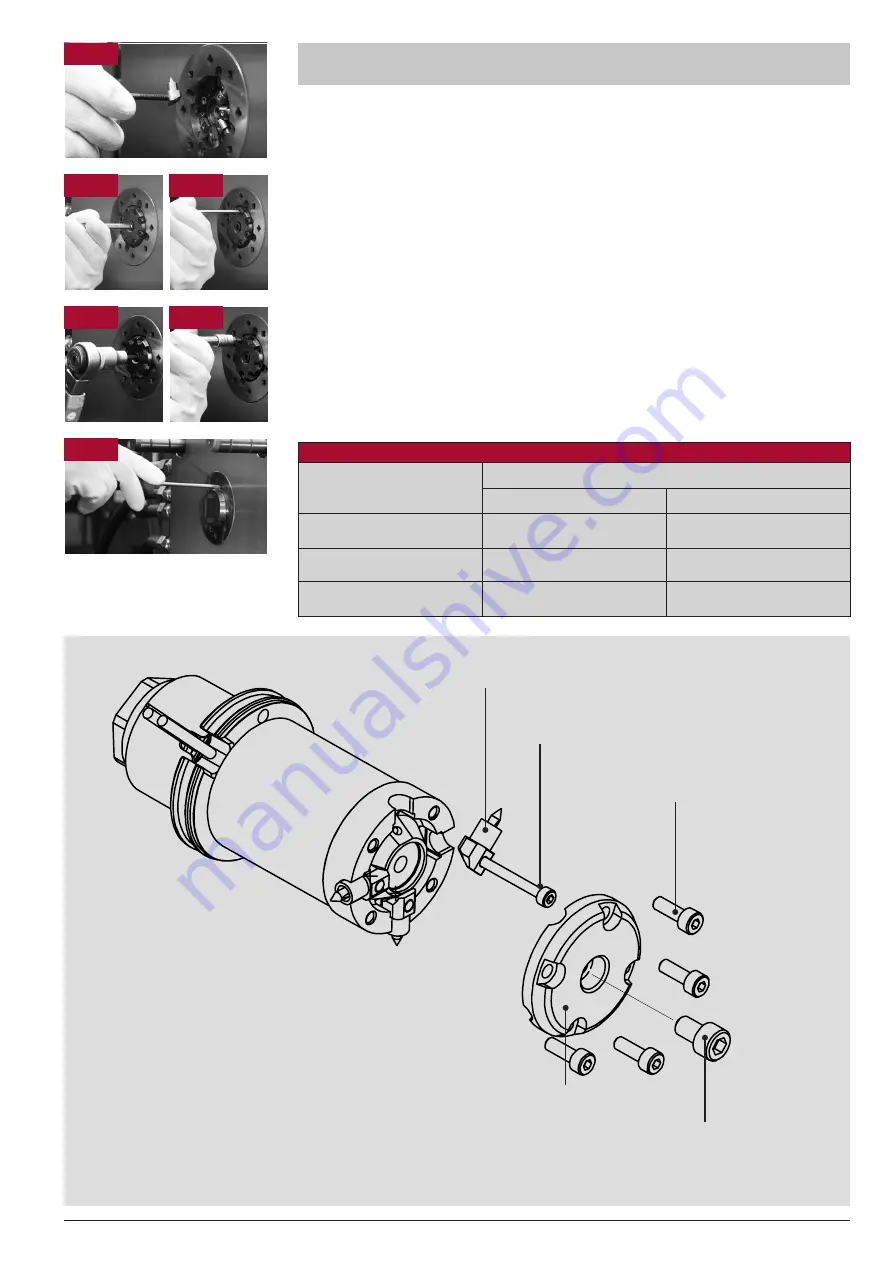

Tip insert assembly for the

HPS III-MHR nozzle, radial version

1x socket head screw

ISO 4762 M6x10

1. Install the tip inserts. Please ensure that they are positioned correctly and that the sealing

surfaces between tip insert and nozzle are clean. A screw M4 or a threaded rod can be

screwed into the tip insert as an assembly aid.

2. Attach clamping cover and fix it with central socket head screw M6x10.

Use half of the defined torque (please see chart).

3. Screw in socket head screws M4x12 crosswise. Use half of the defined torque

(please see chart).

4. Heat up nozzle to processing temperature (maximum nozzle temperature 350 °C / 662 °F)

and warm up the mould until the mould temperature is reached. Keep the resulting ΔT

(difference between processing and mould temperature) for at least 10 minutes before

finally retightening the screws with the matching torque. Not adhering to this procedure can

result in damaged sealing sleeves and leakage.

5. Retighten central socket head screw M6x10 with defined torque (see table).

6. Retighten socket head screws M4x12 crosswise with defined torque (see table).

7. Install heat protective cover.

Page 3/4

Tip insert

Assembly aid (socket head screw M4)

4x socket head screw

ISO 4762 M4x12-12.9

1x socket head screw

ISO 4762 M6x10-12.9

Clamping cover

The number of

the M4x12 socket

head screws varies

depending on

the number of

tip inserts.

1

5

6

7

2

3

Versions of

HPS III-MHR

radial nozzle

Nozzle

Torque (unlubricated)

M4x12 - 12.9

M6x10 - 12.9

MHR 93/95 /

MHR100 / MHR111

4 Nm (3.0 ft·lb)

11 Nm (8.1 ft·lb)

MHR112 / MHR122

2.5 Nm (1.8 ft·lb)

Central socket head screw not

available for this version

MHR200

4 Nm (3.0 ft·lb)

2 tips: 6 (4.4 ft·lb)

4 tips: 11 (8.1 ft·lb)