www.evolutionfury.com

24

NOTE:

A workshop dust extraction device

can be connected to the extraction port

found at the rear of the machine if required.

2. Table Saw On/Off Switches (Fig. 24)

The On/Off Switch is a two (2) button

latching type. The buttons are located on the

Front Left Hand side of the Cutting Handle.

• Push the Green (I) button to start the motor.

• Push the Red (O) button to stop the motor.

3. Rip cutting

NOTE:

The Fury6 in Table Saw mode is

optimally suited for the cutting of thin sheet

material such as laminate flooring etc.

Rip cutting is cutting along the length of a

piece of material rather than across it.

Rip cutting should always be done with the

Rip Fence set to the desired width and on

the RH side of the machines table.

NOTE:

Check that the Rip Fence is locked

in position and is parallel to the saw blade.

Check that the riving knife is properly

aligned with the saw blade.

When ripping small section material a Push

Stick should be used to feed/guide the final

300mm of the material past the blade. A

Push Stick should always be used when

making cuts of less than 300mm.

NOTE:

A Push Stick

(Fig. 25)

is provided

with the Fury6 and has a dedicated storage

position to the front of the machine.

We recommend that when not in use the

Push Stick is stored on the machine.

When ripping long boards or large panels

always use a remote work support or enlist

competent trained help.

Feed the workpiece through the saw

keeping it indexed against the Rip Fence.

Use smooth, steady pressure and employ a

Push Stick when necessary.

Hands should never be in line with

the

blade.

MAINTENANCE AND ADJUSTMENTS

WARNING:

Ensure that the machine is

disconnected from the mains supply before

any maintenance tasks or adjustments are

attempted.

Cleaning

After each use the machine should be

cleaned. Remove all sawdust etc from the

visible parts of the machine with a vacuum

cleaner. A vacuum cleaner can also be

connected to the machine dust extraction

port at the rear of the machine. This should

remove debris from the inside of the

machine. Never use solvents to clean plastic

parts, as solvents can damage them. Clean

only with a soft slightly damp cloth.

Fig. 25

Fig. 24

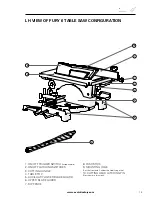

Содержание Fury 6

Страница 2: ...www evolutionfury com 2 03 GB...

Страница 29: ...www evolutionfury com 29...

Страница 30: ...www evolutionfury com 30...

Страница 31: ...www evolutionfury com 31...