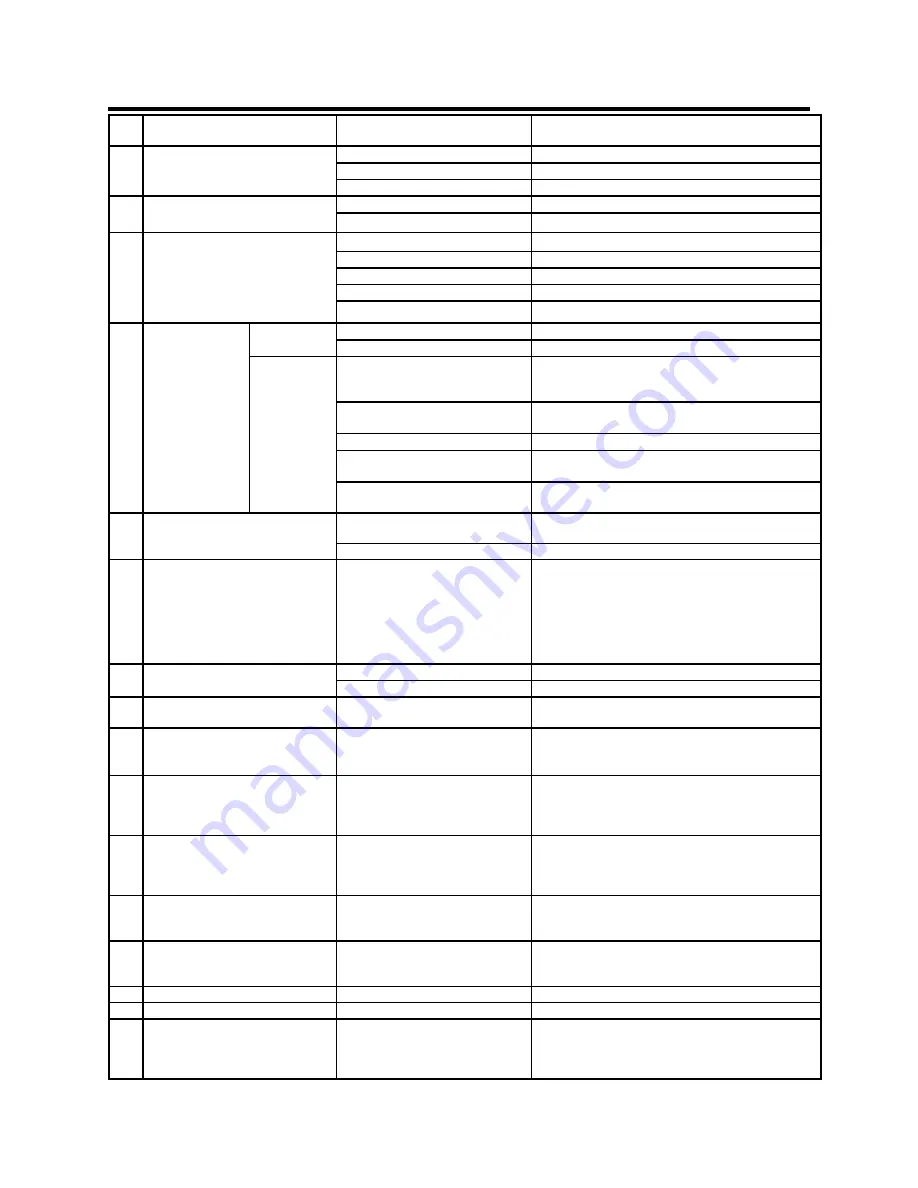

32

Section 3

Trouble Shooting

NO

.

Trouble

Possible Cause

Solution

1

Unit is switched on, but the power

light isn

’

t on

Switch damaged.

Replace.

Unit Fuse damaged.

Replace.

Power breaker tripped.

Reset.

2

After welding machine is over-

heating and the fan does not work

Fan damaged.

Check fan housing and fan. Replace if necessary.

Fan power connector is loose.

Tighten wires, check for dislodged connectors.

3

When torch switch is pressed, no

gas Flows

No gas in the gas cylinder.

Replace.

Gas pipe leaks gas.

Resolve .

Gas solenoid valve damaged.

Check and clean/replace.

Torch switch damaged.

Repair or Replace.

Control board damaged.

Inspect the circuit.

4

Wire

-

feeder does

not work

Wire reel

does not turn

Motor damaged/Fuse blown.

Check and Replace.

Control circuit damaged.

Check the board.

Wire reel

turns

The tensioner is loose or wire slips

on rollers. Wrong size drive roll.

Wire is not mated in drive groove.

Increase tension. Check for proper drive roll size/type.

Make sure wire is in groove not riding on top of the

drive roller shoulder.

The drive roller doesn

’

t fit the

diameter of weld wire.

Change roller or wire size to match.

Wire Spool is damaged.

Change out wire spool.

Gun liner is jammed.

Repair or change it, clear wire from liner/clean liner

with compressed air.

Contact Tip is jammed because of

slag or burn back.

Clean or replace. If with Aluminum, increase tip size to

next size.

5

No arc, or no output voltage

Work clamp engaged in wrong

connector.

Change polarity.

Control circuit damaged.

Check the circuit.

6

Welding stops and warning light is

on, Wire continues feeding but no

arc

Self

-

protection has engaged.

Check over

-

voltage, over

-

current, over

-

temperature,

lower

-

voltage and over

-

temperature. Allow unit to cool

if over heated. If an OC, use a shorter wire stick out or

smaller diameter wire or reduce power settings with

large diameter wires. Check power plug for problems.

If easily tripped the Resistor value too low. (Contact

Everlast if OC is tripping regularly with normal settings.)

7

Welding Voltage/Current is uncon-

trollable

Potentiometer damaged.

Repair or Replace it.

Control board damaged.

Check the circuit.

9

Intermittent Arc/ Wandering arc

Work Clamp is not secure or it is

damaged. Too windy/breezy.

Check and/or Work Clamp, change position of clamp

and attach direct to the work. Move out of wind.

10

Excessive spatter

Voltage too high too high arc force/

Too high wire speed. Too much

torch angle. Wrong size nozzle

Lower voltage or increase wire speed. Check torch

angle for less than 15° push or pull. Change arc force

settings to reduce spatter. Change nozzle size.

11

Weld sooty or oxidized looking

Poor metal prep, poor gas flow, too

much torch angle, wrong gas type,

windy or breezy. Plugged nozzle

Thoroughly clean metal, check gas flow and reposition

gun so gas flow is not creating turbulence. Move in-

doors if necessary. Reposition the welder so its fan will

not blow on the weld area. Clean nozzle.

12

Bird nesting of the wire around the

drive roll

Jammed gun liner, wire too soft

(aluminum), gun hose is kinked or

coiled too tightly. Too much ten-

sion / pressure on wire feeder .

Reduce wire feed tension so that drive will slip if it

encounters too much resistance Check Gun and liner

and replace if necessary. Straighten cable.

13

Wire feeds irregularly

Wrong drive roller or wrong size

drive roller, too little tension on

wire, wire in wrong groove.

Check and match wire size to groove size, increase

tension on drive rollers. Check to make sure the wire is

not riding on the shoulder of the drive roller.

14

Wire burns back and seizes in tip

Wrong contact Tip size or too much

burn back time set.

Match tip size for wire diameter. Reduce burn back

time. If using with aluminum, use tip designed for

aluminum or use one size larger tip than the wire.

15

Nozzle arcs to work piece welding

Nozzle plugged with spatter

Check/clean nozzle and use a nozzle dip.

16

In Stick mode will not arc

Cables not connected, inverter issue

Check connections.

17

In Stick mode, the rod sticks

Arc force control is set too low, arc

striking method is poor, wrong

polarity, too low of amperage. Wet

welding rods or wrong kind.

Check polarity. Increase arc force control. Change arc

striking method. Increase amperage. Use fresh welding

rods when possible.