www.eurolube.com

EUROLUBE EQUIPMENT AB

–

PART NO 26700, 257-51, 257-52 / ART.NR. 26700, 257-51, 257-52

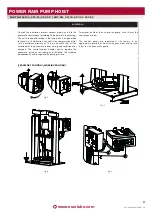

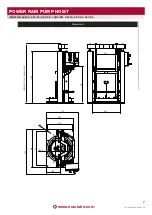

POWER RAM PUMP HOIST

10

www.eurolube.com

10

842 806 R. 09/12

Samoa Industrial, S.A. · Box 103 Alto Pumarín · 33211 Gijón - Asturias Spain · Tel.: +34 985 381 488 · Fax.: + 34 985 384 163

2012_09_26-10:30

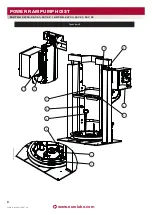

Pos.

Part No.

Description

Qty.

1

739 100

Inductor plate body

1

839 500

Gasket cleaning plate (lower)

1

739 201

Strip for closing inferior

4

739 202

Strip for closing upper

4

839 501

Gasket cleaning plate (upper)

1

940 044

Hexagonal nut M10x25 DIN-933

24

942 210

Spring washer B10 DIN-127

24

2

951 452

Limiter valve 3/2 NC R1/8"

1

951 482

Straight connector R1/8" to pipe of 6 mm

2

951 433

Limiter silencer R1/8"

1

3

951 459

In-line anti-return for pipe of 8 mm

1

951 461

Straight connector R1/4"M for pipe of 8 mm

1

4

739 210

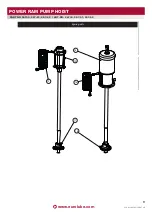

Bleed rod set 1/2"

1

5

739 214

Pump support

1

960 306

Stauff clamp G3/4"

2

940 221

Flat-headed bolt M6x60 DIN-603

4

941 107

Self-locking nut M6 DIN-985

4

6

839 200

Pneumatic control panel

1

7

739 217

Air receiver

1

960 306

Stauff clamp G3/4"

2

940 384

Cylindrical bolt M6x45 DIN-912

4

941 306

Cap nut M6 DIN-917

4

951 484

Connector << T >> R1/2” for pipe of 8 mm

1

951 485

Compact elbow 1/2” for pipe of 8 mm

1

8

950 032

Drum stop

1

940 231

Flat-headed bolt M8x20 DIN-603

1

941008

Hexagonal nut M8x1,25 DIN-934

1

9

951 442

Pneumatic cylinder

1

10

951 486

Straight bulkhead connector for pipe of 8 mm

1

951 483

Straight bulkhead connector for pipe of 6 mm

2

11

931 250

Extendible hose ES 4x6x2 A

2

12

931 251

Extendible hose ES 5,5x8x5 A

1

13

740 600

B.N.G. PM3+3 60:1/920

1

42-004-09-39

Pump support PM 3+3

1

940 922

Screw M6x20 DIN-7380

7

941 107

Self-locking nut M6 DIN-985

4

942 206

Spring washer B6 DIN-127

3

14

740 500

B.N.E. PM6 55:1/920

1

940 922

Screw M6x20 DIN-7380

6

941 107

Self-locking nut M6 DIN-985

6

15

243 502

Hose 12x8 – M3/8"G. LENGTH = 2 m

1

945 556

Connection reducer R1/2” R3/8” MF

1

16

243 502

Hose 12x8 – M3/8”G. LENGTH = 2 m

1

945 556

Connection reducer R1/2" R3/8" MH

2

946 605

Steel and elastomer gasket J-12

2

Spare parts

55:1 Pump

25755

50:1 Pump

25740