SECTION 5

PCM-875A Plasmarc Cutting System

Maintenance

5-9

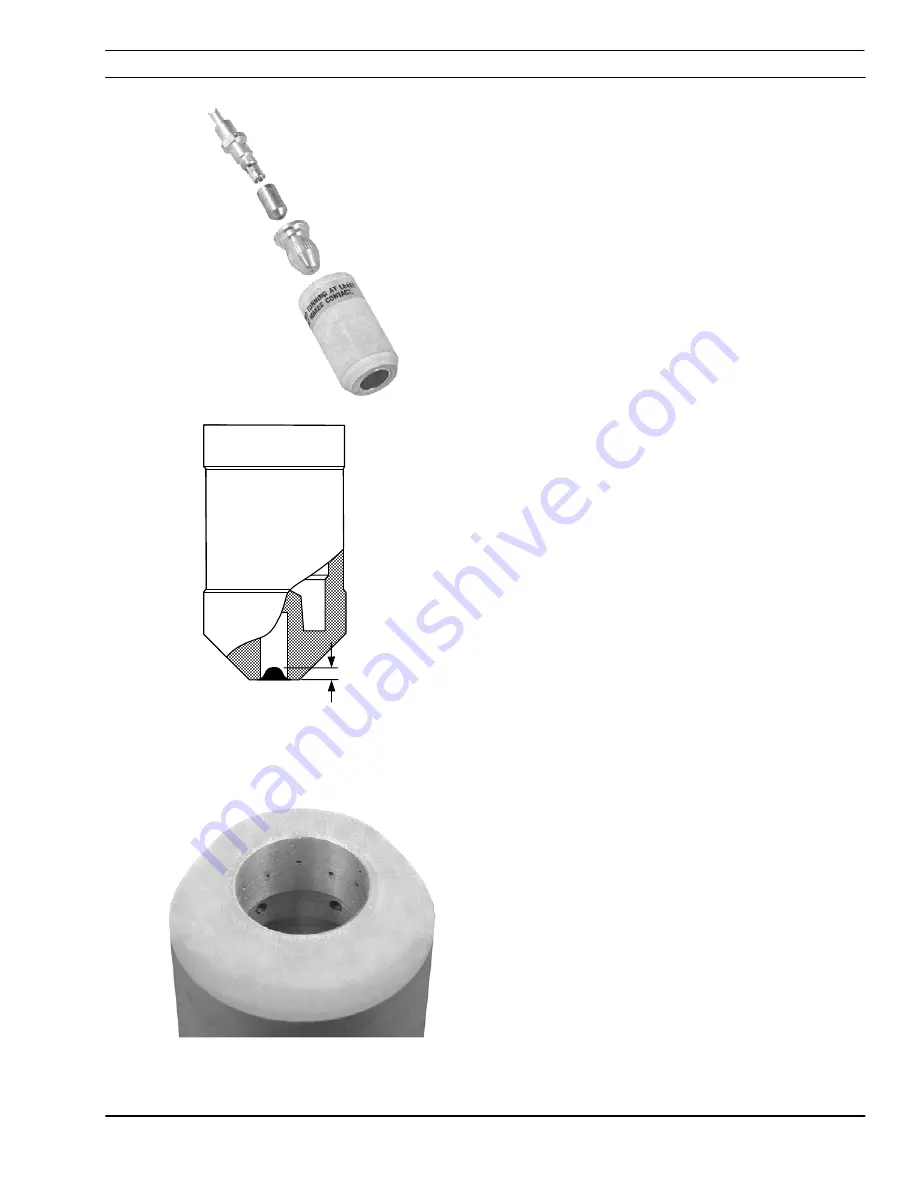

3. Remove the nozzle and electrode assembly

from the shield and inspect for wear. The nozzle

orifice should be round at both the entrance and

the exit. If the nozzle orifice is worn in an oval

shape or shows other signs of damage at either

end, it should be replaced. The inside of the nozzle

may have light gray deposits from the electrode.

These may be removed with steel wool but care

must be taken to remove all traces of the steel

wool afterward.

1,5 mm

If the electrode has a pit that is more than 1.5mm

deep at its center, replace it. Grasp the electrode

holder with the fingers using the two flats and

grasp the electrode between the thumb and finger

of the other hand and twist.

Inspect electrode insulator and electrode holder

assembly for signs of damage such as arc tracking

or cracking and replace them if any are found.

Insure that the baffle tube is securely threaded into

the electrode holder, but do not over tighten. Use

the small hex end of the plastic wrench in the

spare parts kit.

After installing the electrode insulator onto the

electrode holder assembly, install electrode by

reversing the procedure used to remove it. Note

that firm tightening of the electrode by hand is

sufficient. The use of tools such as wrenches or

pliers is not required or recommended.

4. Inspect heat shield for signs of damage or

wear. The gas holes inside shield should not be

blocked by debris, and there should be no signs of

arcing anywhere inside the shield. The outer

insulating jacket of the shield should not be

severely charred or eroded. Replace the heat

shield if any of the above damage is found.

.

Содержание PCM-875A

Страница 27: ...SECTION 2 PCM 875A Mechanized Plasma Cutting System Description 2 5 2 4 2 Dimensions 435 mm 34 9 mm ...

Страница 48: ...SECTION 3 PCM 875A Mechanized Plasma Cutting System Installation 3 20 This page intentionally left blank ...

Страница 72: ...SECTION 4 PCM 875A Mechanized Plasma Cutting System Operation 4 24 This page intentionally left blank ...

Страница 84: ...SECTION 5 PCM 875A Plasmarc Cutting System Maintenance 5 12 This page intentionally left blank ...

Страница 112: ...SECTION 7 Replacement Parts 7 4 PCM 875A Power Console 230V P N 0558003356 230V CE 1 2 3 4 5 6 7 8 9 10 11 12 ...

Страница 120: ...SECTION 7 Replacement Parts 7 12 PCM 875A Power Console 400V P N 0558003357 400V CE 1 2 3 4 5 6 7 8 9 10 ...

Страница 126: ...SECTION 7 Replacement Parts 7 18 7 5 Remote Arc Starter RAS 2 P N 0558003670 A A B B View B B View A A 1 2 3 4 4 ...

Страница 128: ...SECTION 7 Replacement Parts 7 20 Remote Arc Starter RAS 2 P N 0558003670 1 2 3 4 5 6 7 5 REF 8 9 10 11 12 12 ...

Страница 130: ...SECTION 7 Replacement Parts 7 22 7 6 PT 20AMX Plasmarc Cutting Torch 1 4 6 7 8 9 10 11 12 13 14 16 2 3 5 17 18 1 15 ...

Страница 132: ...SECTION 7 Replacement Parts 7 24 PT 20 AMX Front End and Spare Parts Kit 1 2 3 4 5 8 6 7 9 ...

Страница 134: ...SECTION 7 Replacement Parts 7 26 This page intentionally left blank ...

Страница 135: ...See back of Title Page for revision list ...