-- 10 --

mxx02cwe

6

OPERATION

General safety regulations for the handling of the equipment can be found on

page 3. Read through before you start using the equipment!

WARNING -- TIPPING RISK!

Fasten the equipment -- particularly if the ground is uneven or sloping.

6.1

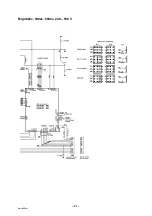

Connections and control devices

1

Mains supply switch

6

Control cable socket (from / to wire feeder)

2

Indicating lamp, power supply ON

7

Connection for weldng current cable (+)

3

Indicating lamp, overheating / fault

8

Connection BLUE for cooling water to the

wire feed unit

4

Connection for weldng current cable (+)

9

Connection RED for cooling water from

the wire feed unit

5

Connection for weldng current cable (--)

6.2

Overheating protection

The power source has one thermal overload trip which operates if the internal

temperature becomes too high, interrupting the welding current and lighting the

orange indicating lamp on the front of the unit. It resets automatically when the

temperature has fallen and the indicating lamp will go out.

GB

Содержание Origo Mig 4002c

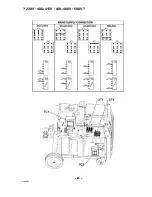

Страница 13: ... 13 document ...

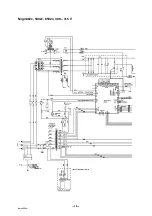

Страница 14: ...Diagram 14 dmxx02cw Mig 4002cw 5002cw 6502cw 400 415 V ...

Страница 15: ... 15 dmxx02cw Mig 4002cw 5002cw 6502cw 400 415 V ...

Страница 16: ... 16 dmxx02cw Mig 4002c 5002c 6502c 400 415 V ...

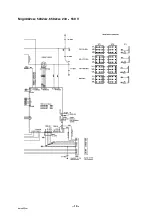

Страница 17: ... 17 dmxx02cw Mig 4002c 5002c 6502c 400 415 V ...

Страница 18: ... 18 dmxx02cw Mig 4002cw 5002cw 6502cw 230 550 V ...

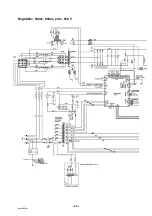

Страница 19: ... 19 dmxx02cw Mig 4002cw 5002cw 6502cw 230 550 V ...

Страница 20: ... 20 dmxx02cw Mig 4002c 5002c 6502c 230 550 V ...

Страница 21: ... 21 dmxx02cw Mig 4002c 5002c 6502c 230 550 V ...

Страница 22: ... 22 vrxx02c 230V 400 415V 440 460V 500V ...