Содержание Caddy Tig 1500i VRD

Страница 2: ......

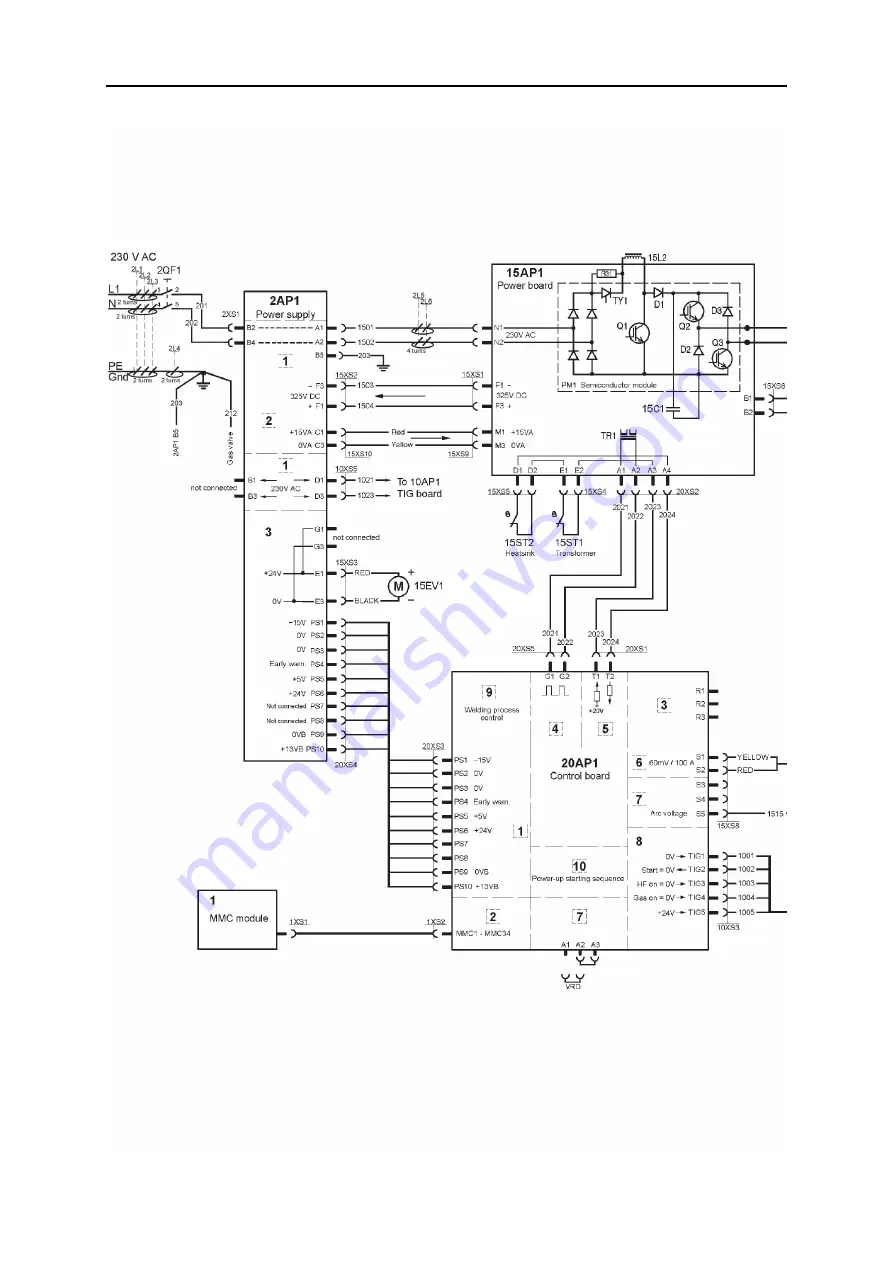

Страница 17: ...DIAGRAM 0460 826 374 17 ESAB AB 2019 DIAGRAM Tig 1500i TA34 ...

Страница 18: ...DIAGRAM 0460 826 374 18 ESAB AB 2019 ...

Страница 19: ...DIAGRAM 0460 826 374 19 ESAB AB 2019 Tig 1500i TA33 ...

Страница 20: ...DIAGRAM 0460 826 374 20 ESAB AB 2019 ...

Страница 21: ...DIAGRAM 0460 826 374 21 ESAB AB 2019 Tig 2200i TA33 TA34 ...

Страница 22: ...DIAGRAM 0460 826 374 22 ESAB AB 2019 ...

Страница 27: ...ACCESSORIES 0460 826 374 27 ESAB AB 2019 ...