11

ROUTINE SNOW BLOWER

MAINTENANCE

It is the operator’s responsibility to make daily inspections of the tractor and attachment for damage, loose

bolts, fluid leaks, or anything else that could cause a potential service or safety problem. Preventive

maintenance is the easiest and least expensive type of maintenance.

IMPORTANT:

Bolts and set screws can loosen after initial usage. After first two hours of operation check all

bolts and set screws.

WARNING: Lower the attachment to rest on the skid shoes, shut down the engine, wait for

all motion to stop, and set park brake before leaving the operator’s seat to perform service

of any kind.

Use No. 2 lithium base gun grease when lubricating

all Snow Blower grease fittings.

Grease the three chute roller guides every

8 hours

of operation.

IMPORTANT: These are requirements. It is the

responsibility of the owner/operator to make

sure the attachment is serviced on a daily

basis. Improper maintenance can cause

extensive damage to the attachment and/or

your equipment.

Grease the bearing on each end of the auger after

every

40 hours

of operation.

8

40

LUBRICATION

Clean engine oil

No. 2 Lithium

base gun grease

Содержание 620RP

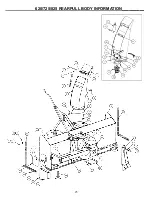

Страница 25: ...25 620 725 825 REARPULL BODY INFORMATION__________ ...

Страница 27: ...27 620 725 825 REARPULL BODY INFORMATION________ ...

Страница 29: ...29 620 725 825 REARPULL DRIVE INFORMATION VIEWED FROM TOP VIEWED FROM FRONT ...

Страница 36: ...36 P N 300620 Date Printed 2 27 2017 Erskine Attachments LLC Printed in U S A ...