Metalarm

™

Series 3500 Metal Detectors

9

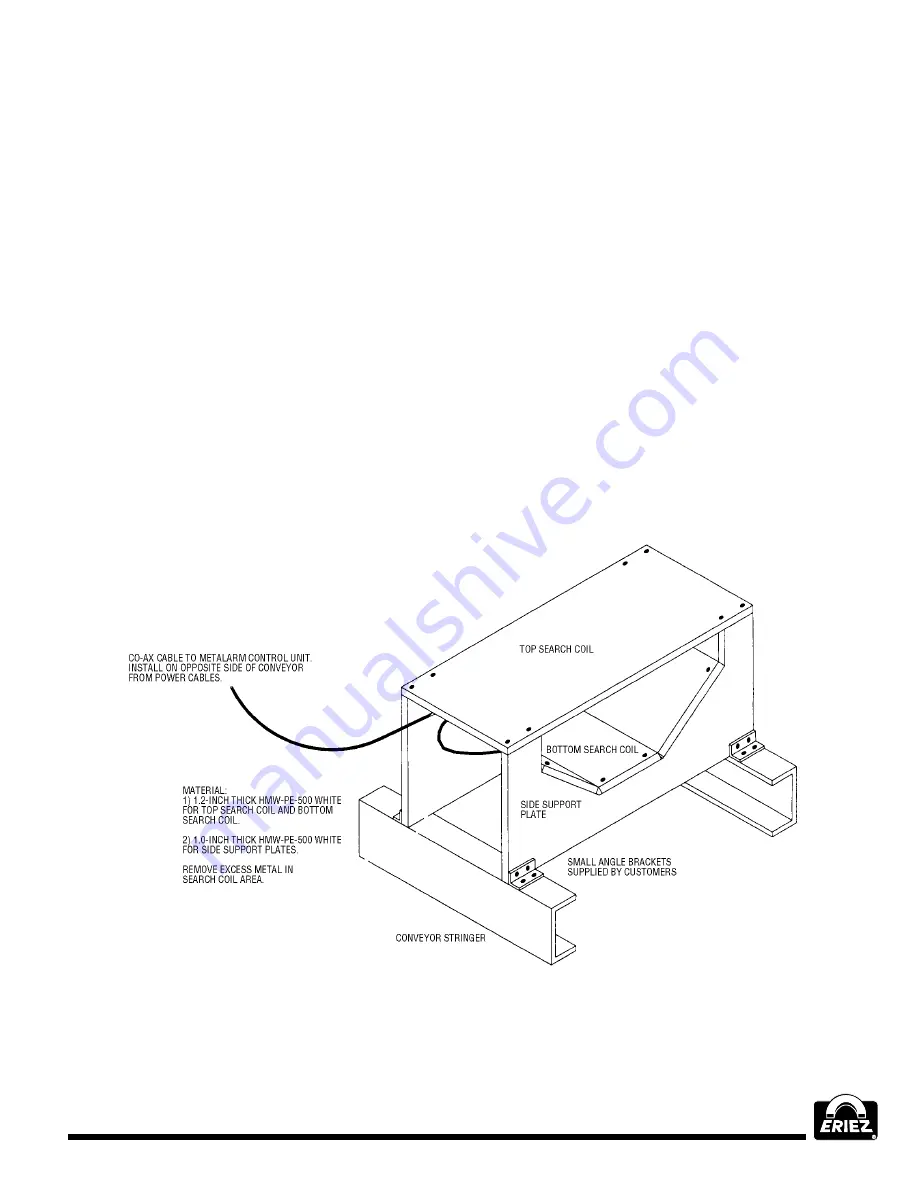

FIGURE 4

User supplied stainless steel “L” brackets are

suggested for securing the search coil assembly to

the conveyor. Brackets should be fitted to the coil. The

area for this purpose is shown on the coil assembly

drawing. (See Figure 4)

The search coil should then be bolted to the conveyor

frame so that the coil socket is on the opposite side of

the conveyor frame from any heavy-duty cables

or wiring.

Fit the top search coil section and bolt it in place.

A recommended idler spacing of 48"- 60" should apply

to the infeed and outfeed idlers adjacent to the search

coil. An idler isolation kit is recommended and may

be purchased from the factory. The idler isolation kit

provides suitable materials to electrically insulate the

idlers from the conveyor frame. Insulating the idlers

directly adjacent to each side of the search coil will help

to alleviate any possible false tripping. Electrical loops

can be created from the metal detectors field in relation

to the surrounding metal. The idlers, either side of the

search coil, should be checked to see that all nuts and

bolts are tight.

In the case of series connection, connect the lower

coil using the short length of cable provided to the

unmarked socket on the top coil. The cable to connect

the search coil to the control unit should be connected

to the socket marked ‘CU’ on the top search coil. In

the case of transmit/receive mode operation, both coils

are connected directly to the control unit.

In both cases make sure the cables are secured to the

conveyor frame and protected to prevent them

being damaged.

The search coil coax cable must not cross directly

under the search coil, as this may cause false tripping

to occur. The cable should be replaced should any

nicks in its outer cover occur.

If standard metal conduit must be used be used to

protect the coil cable(s), separate conduits must be

used for each cable; receiver and transmitter. If a clip

detector is required, the cable may be run in the same

conduit as the receiver or transmitter coil.