High-Speed Drum: Model DF

7

Magnet Rotation

On the drum shaft there is either an arrow indicating

the center of the magnet arc or a colored section

indicating the magnet arc. The normal position for the

magnet element has the arc center slightly elevated

in the front half of the drum. The drums are usually

shipped with the magnet arc hanging down and

must be repositioned for startup.

The magnetic material will stand up in the center

of a magnetic pole where the field is perpendicular

to the material flow. At the pole edge the magnetic

material will lay down and point towards the next pole

or away from the magnet arc almost tangent to the

drum surface. Sometimes this pole edge can be seen

as a line of magnetics before a drum cleat wipes the

magnetics away.

The splitter tip will separate magnetics better if it is

located between the pole edges, rather than in the

center of a pole. If the edge can be seen, the splitter

tip can be adjusted accordingly. However, sometimes

the splitter cannot be adjusted to the optimum length.

In this case, the magnet rotation can be adjusted by

loosening the set screws on the flange mounted on

the non-drive side of the drum. The magnet adjusting

arm turnbuckle is used to adjust the magnet to fit the

splitter position and the set screws re-tightened.

Bearing Replacement

The standard units have four bolt flange bearings

which are sealed and greaseable. Remove the drum

from the housing. Support the drum shaft on blocks to

take the weight of the bearings. When removing the

bearings you should first clean the shaft thoroughly

with solvent then attempt to remove the four bearing

mounting bolts and bearings set screws.

Pry between the bearing and the drum head to slide

the bearing off the end of the shaft. If the bearing is

not moving (usually due to the head flexing inward),

you will have to remove all the fasteners holding the

drum head to the shell.

You would then use the tapped holes in the head with

threaded rod and porta power pushing against the

end of the shaft. Make sure to match mark the heads

and shell before going this route. (See Figure 5)

To Install a New Bearing

1. Inspect the shaft. Remove burrs, verify diameter

and clean mounting surface.

2. Place bearing on the shaft. Apply light film of oil.

Do not hammer onto shaft.

3. Bolt housing to mounting surface. Make sure the

magnetic element is centered between the heads.

Rotate shaft to make sure it turns smoothly.

4. Bolt up the bearing to the mounting surface and

torque bolts to 75 ft.-lbs.

5. With two setscrews, torque set screw ‘A’ to ½

recommended torque (73-95ft.-lbs.), torque set

screw ‘B’ to full torque. Torque setscrew ‘A’

to full torque.

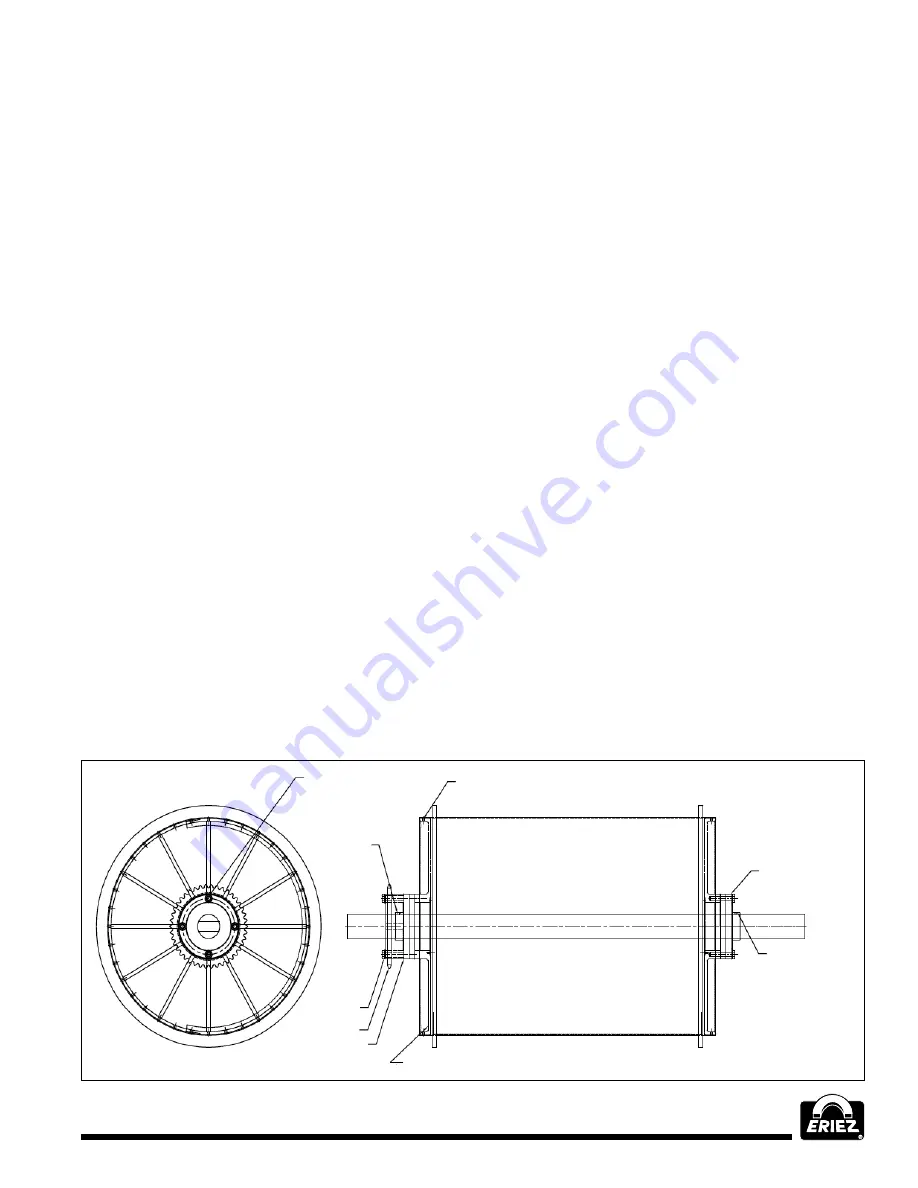

Figure 5

Flange bearing bolts

Bearing

set screws

use blue

loctite

Fasteners holding

head to shell

Flange bearing

Spot shaft @

assembly four

locations

Drum head

Flange bearing

max T.I.R.

sprocket .020"

Sprocket

Torque to

75 ft lbs

use blue

loctite