26

Digitax ST User Guide

Issue: 5

•

AC supply to external EMC filter (when used)

•

AC supply (or external EMC filter) to drive

•

Drive to motor

•

Drive to braking resistor

•

When operating in ambient >45

°

C UL 75

°

C cable should be used.

Cable sizes are given for guidance only and may be changed depending

on the application and the method of installation of the cables.

The mounting and grouping of cables affect their current capacity, in

some cases a larger cable is required to avoid excessive temperature or

voltage drop.

Input cable sizes should generally be regarded as a minimum, since

they have been selected for co-ordination with the recommended fuses.

Output cable sizes assume that the maximum motor current matches

that of the drive.

Where a motor of reduced rating is used the cable rating may be chosen

to match that of the motor.

To ensure that the motor and cable are protected against overload, the

drive must be programmed with the correct motor rated current.

•

Cable lengths in excess of the specified values may be used only

when special techniques are adopted; refer to the supplier of the

drive.

•

The default switching frequency is 6 kHz.

The drive power terminals are designed for a maximum cable size of 4.0

mm

2

(minimum 0.2 mm / 24 AWG).

Where more than one cable per terminal is used the combined

diameters should not exceed the maximum.

The terminals are suitable for both solid and stranded wires.

Table 4-9 Motor cable size and maximum lengths

High-capacitance cables

The maximum cable length is reduced from that shown in Table 4-9 if

high capacitance motor cables are used.

Most cables have an insulating jacket between the cores and the armor

or shield; these cables have a low capacitance and are recommended.

Cables that do not have an insulating jacket tend to have high

capacitance; if a cable of this type is used, the maximum cable length is

half that quoted in the tables. (Figure 4-3 shows how to identify the two

types).

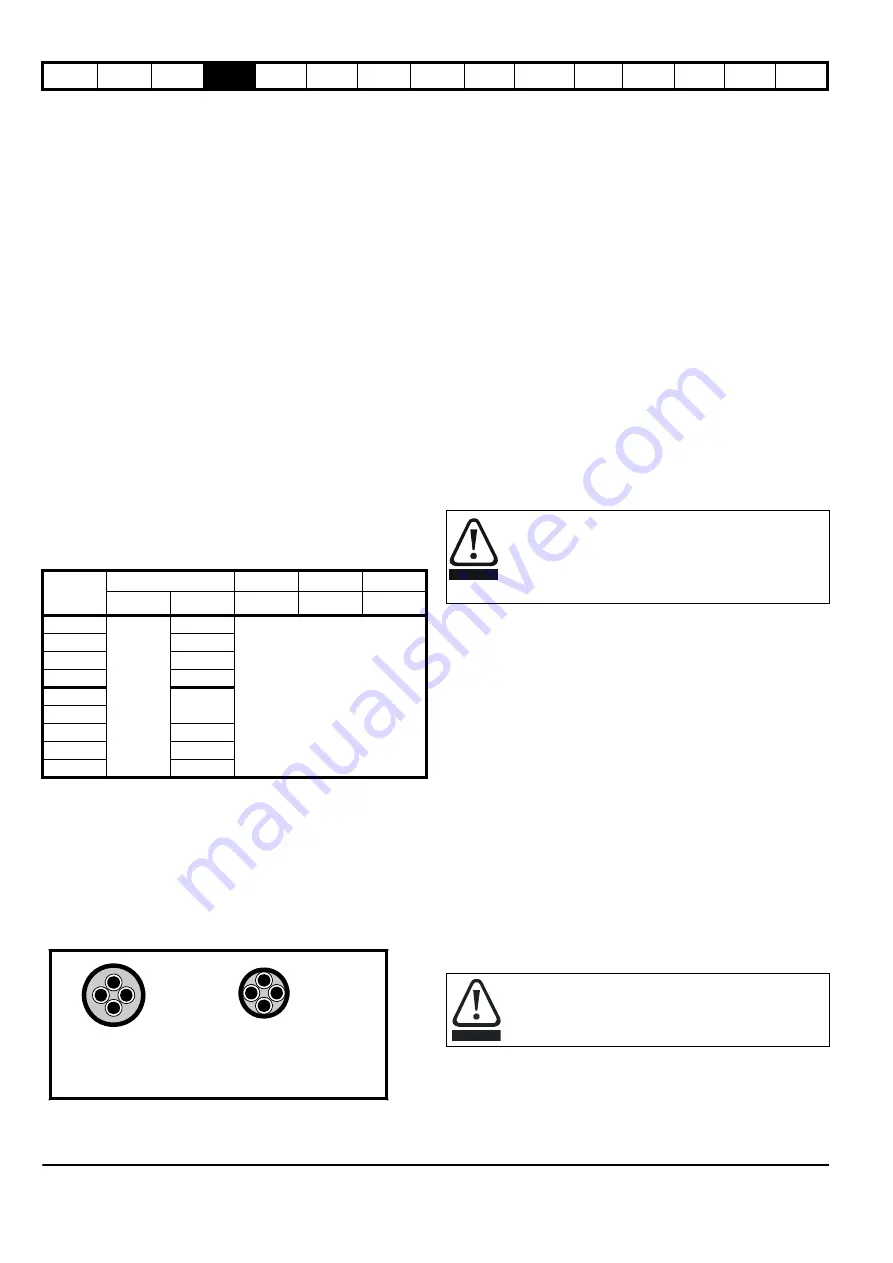

Figure 4-3 Cable construction influencing the capacitance

The cable used for Table 4-9 is shielded and contains four cores. Typical

capacitance for this type of cable is 130 pF/m (i.e. from one core to all

others and the shield connected together).

4.7.2 Motor winding voltage

The PWM output voltage can adversely affect the inter-turn insulation in

the motor. This is because of the high rate of change of voltage, in

conjunction with the impedance of the motor cable and the distributed

nature of the motor winding.

For normal operation with AC supplies up to 500 Vac and a standard

motor with a good quality insulation system, there is no need for any

special precautions. In case of doubt the motor supplier should be

consulted.

Special precautions are recommended under the following conditions,

but only if the motor cable length exceeds 10 m:

•

AC supply voltage exceeds 500 V

•

DC supply voltage exceeds 670 V

•

Operation of 400 V drive with continuous or very frequent sustained

braking

For the other cases listed, it is recommended that an inverter-rated

motor be used. This has a reinforced insulation system intended by the

manufacturer for repetitive fast-rising pulsed voltage operation.

If it is not practical to use an inverter-rated motor, an output choke

(inductor) should be used. The recommended type is a simple iron-cored

component with a reactance of about 2 %. The exact value is not critical.

This operates in conjunction with the capacitance of the motor cable to

increase the rise-time of the motor terminal voltage and prevent

excessive electrical stress.

4.7.3 Output contactor

A contactor is sometimes required to be installed between the drive and

motor for safety purposes.

The recommended motor contactor is the AC3 type.

Switching of an output contactor should only occur when the output of

the drive is disabled.

Opening or closing of the contactor with the drive enabled will lead to:

1. OI.AC trips (which cannot be reset for 10 seconds)

2. High levels of radio frequency noise emission

3. Increased contactor wear and tear

The Drive Enable terminal (T31) when opened provides a Safe Torque

Off function. This can in many cases replace output contactors.

For further information see section 4.17

4.8 Braking

The internal braking resistor can be used with the drive even though its

resistance is lower than the minimum resistance values given in

Table 4-11, because of the following reasons.

•

The braking resistor overload protection function in the drive is set

up to limit the power dissipated in the resistor.

•

The braking resistor is installed with a thermistor which will trip the

drive if the resistor is too hot.

•

The power rating of the resistor is only 50 W

If an external resistor is used with the drive, its resistance must be equal

to or greater than the value given in Table 4-11.

Model

Output cable

6kHz

8kHz

12kHz

mm

2

AWG

m

m

m

DST1201

0.75

24

50

DST1202

22

DST1203

20

DST1204

18

DST1401

24

DST1402

DST1403

22

DST1404

20

DST1405

18

Normal capacitance

Shield or armour

separated from the cores

High capacitance

Shield or armour close

to the cores

If the cable between the drive and the motor is to be

interrupted by a contactor or circuit breaker, ensure that the

drive is disabled before the contactor or circuit breaker is

opened or closed. Severe arcing may occur if this circuit is

interrupted with the motor running at high current and low

speed.

The internal braking resistor for Digitax ST is installed with a

thermistor which must be connected to the drive whenever

the internal braking resistor in installed.

WARNING

CAUTION