34

6.Troubleshooting

6.Troubleshooting

6.Troubleshooting

6.Troubleshooting

This chapter is designed to help the user identify and rectify basic faults or the results

of incorrect operation. When locating a fault, proceed in the order shown in the table.

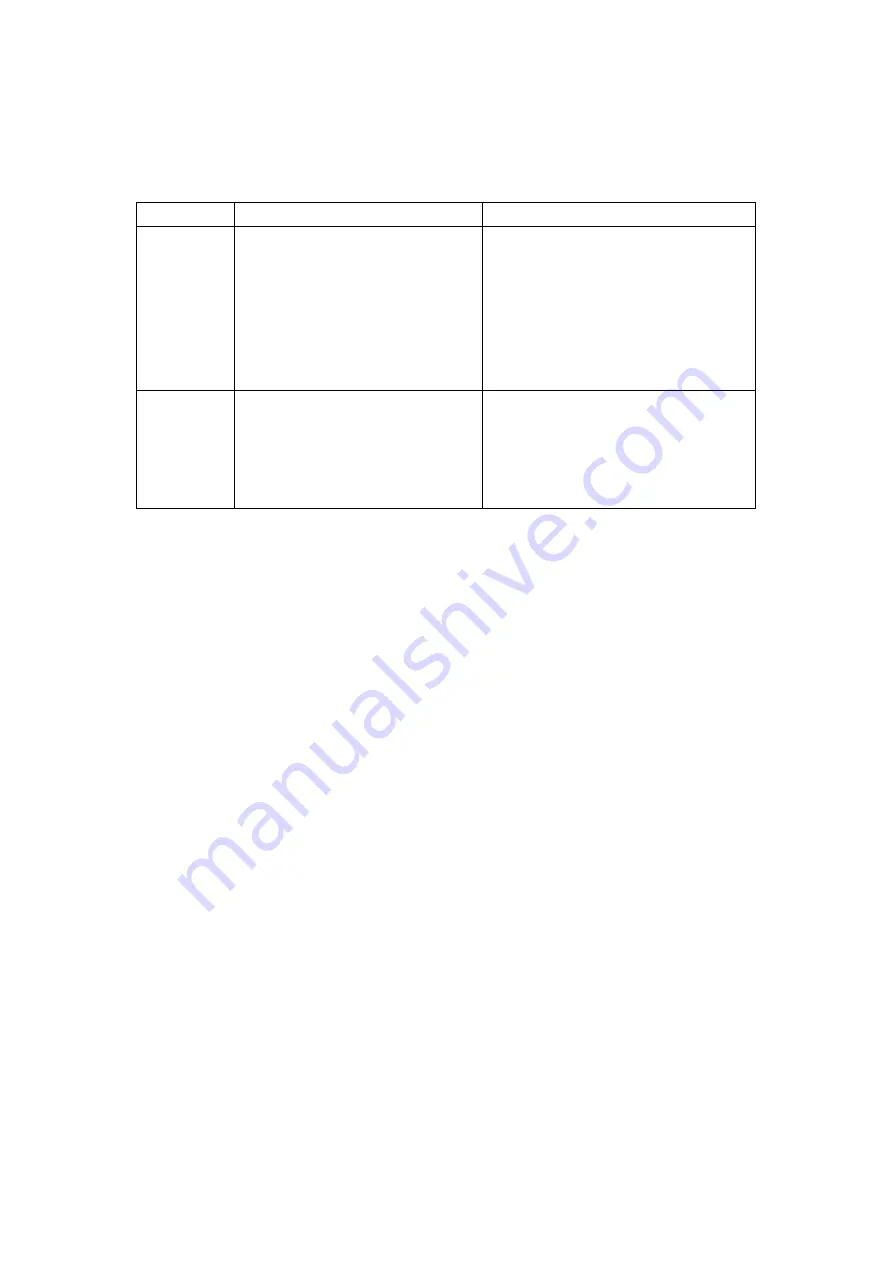

Fault

Possible cause

Action

Truck does

not start.

– Battery connector not

connected

-

Key switch in “0” position

-

Battery charge too low

-

Faulty fuse

-

Truck in charge mode

– Check the battery connector and

connect if necessary.

– Set key switch to “I”

– Check battery charge, charge

battery if Necessary

– Test fuses

– Interrupt charging

Load can

not be

lifted

–

Charge capacity below 20%

/ 40%

–

Hydraulic oil level too low

–

Excessive load

–

Charging the battery

–

Check the hydraulic oil level

–

Note maximum capacity (see

data plate)

If the fault cannot be rectified after carrying out the remedial procedure, notify the

manufacturer ’ s service department ,as any further troubleshooting can only be

performed by specially trained and qualified service personnel.

Содержание EPT20-20RA

Страница 1: ......

Страница 16: ...11 ...

Страница 33: ...28 5 3 2 5 3 2 5 3 2 5 3 2 Lubrication Lubrication Lubrication Lubrication Schedule Schedule Schedule Schedule ...