4

WARNING:

Lift the jack using only lifting eyebolt(s) or

lifting bar. Never attempt to lift the jack by using the

handle assembly. The handle assembly is to be used

only for transporting the jack on its wheels and for positioning

the jack under the jacking point.

5. Using the handle assembly, adjust the jack position so that

the cylinder load cap is centered under the jacking point of

the load.

WARNING:

Be sure that the jack is positioned on a

solid and level support surface, with the lifting cylinder

perpendicular to the ground. Jacking at an angle can

allow the jack to slip out of position, resulting in loss of load. As

required, use a swivel load cap to properly engage angled lifting

points. Refer to Section 5.5 for additional information.

5.0 OPERATION

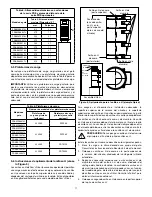

5.1 Control Valves (See Figure 3)

4-Way Manual Valve:

With pump motor running:

• Move lever to the extend position to raise the cylinder.

• Move lever to the retract position to lower the cylinder.

• Center position is neutral/hold. Cylinder stops and holds the

load. This is also referred to as the

“

idle

”

position.

4-Way Air Operated Valve with Pendant:

• To start motor and extend cylinder - press up-arrow button.

• To start motor and retract cylinder - press down-arrow button.

• For neutral/hold - release both pendant buttons. Motor will stop.

Lifting speed and torque can be regulated by using the air

pressure regulator. The regulator should be adjusted to 100 psi

[7 bar]

maximum

with air motor running and air supply valve

completely open.

IMPORTANT:

Pressure settings of above 100 psi [7 bar] will

result in reduced air motor life and will void product warranty.

(

)

Manual Valve: Center position is

NEUTRAL/HOLD

.

Air Operated Valve: Stays in center neutral/hold position

until pendant

down-arrow

or

up-arrow

button is pressed.

RETRACT

(lower)

RETRACT

(lower)

EXTEND

(raise)

EXTEND

(raise)

Figure 3, Control Valve and Pendant Details

5.2 Jacking Safely

You must know the weight of what you intend to lift and choose

a jack with

at least 20 percent

additional capacity.

All persons operating the jack should obtain and be familiar with

the

American National Standards Institute

rules that apply to

hydraulic rams and jacks (ASME ANSI B30.1) or the equivalent

standards used in your country or region.

WARNING:

Never place any part of your body under the

load at any time while it is being lifted, lowered, or

hydraulically supported by the Pow'r-Riser jack.

WARNING:

The Pow'r-Riser jack is intended for lifting

purposes only and should not be used to hydraulically

support the load for any period of time after the lift has

been completed. Support the load with U-Rings or other suitable

load supports immediately after it has been lifted to the desired

height.

WARNING:

Never leave the Pow'r-Riser jack

unattended during operation, even for a brief period of

time. Closely monitor jack operation at all times and be

prepared to stop lifting or lowering immediately.

WARNING:

Do not use the Pow'r-Riser jack outdoors in

windy conditions. Changes in wind direction or velocity

could cause the load to become unstable and fall.

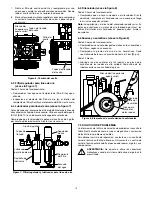

5.3 Operating Instructions (See Figures 3, 4 and 5)

TO RAISE THE LOAD:

1. Be certain that the jack is positioned on a solid and level

surface, capable of supporting the load and the base of

the jack. Be sure that the lifting cylinder is perpendicular to

the ground. See Section 4.4 for additional jack positioning

instructions.

2.

If a high jacking point requires a taller jack, install extensions

and spacers (optional accessories) on the cylinder as

required. Refer to Section 5.4 for installation instructions

and additional information about extensions and spacers.

3. Place a piece of plywood or other compression material

(approximately 1/4" [6,3 mm] thick with good friction

characteristics) between the cylinder load cap and the

jacking point. This will provide a small amount of cushioning

and will also help prevent damage to the jacking point.

4.

To raise the load, open the air supply valve to start the motor.

Then, move the control valve lever to the extend position. If

jack is equipped with pendant, depress the up-arrow button

to start motor and extend cylinder.

CAUTION:

When lifting with more than one jack, be

especially careful to keep the load level. Leveling is best

accomplished by throttling with the air supply valve or

by alternating and stopping jacks to keep the load level enough

so it remains stable.

5.

When load has reached the desired height, move the control

valve lever to the center (neutral/hold) position. If jack is

equipped with pendant, release up-arrow button to return

valve back to the center (neutral/hold) position.

6. Be sure that the proper Enerpac U-Rings are installed on

the cylinder (refer to Section 5.6 for U-Ring installation and

stacking instructions). If U-Rings are not used, be sure that

other load supports of appropriate load rating are in place.

7.

Move the control valve lever to the retract position. Allow the

load to lower until it is supported by the U-Rings or other

load supports. Then, return the lever to the center (neutral/

hold) position. If jack is equipped with pendant, depress and

release the down-arrow button as required, until the load is

supported by the U-Rings or load supports.

4