14

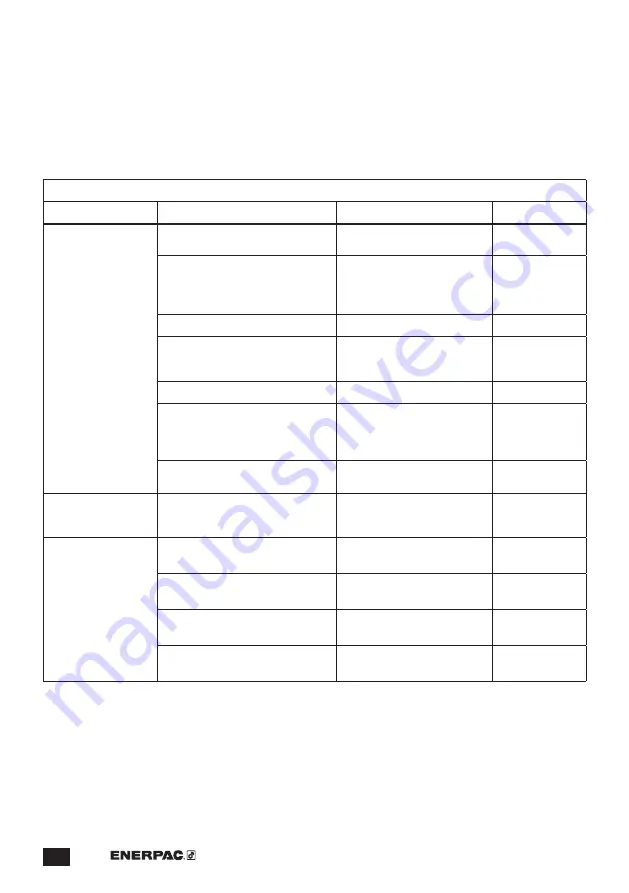

10.0 TROUBLESHOOTING

Refer to the Cutter Troubleshooting Chart (Table 2) for

a list of common hydraulic cutter symptoms, possible

causes and solutions.

For repair service, contact an Enerpac authorized service

center. Inspection and repairs should be performed

only by an Enerpac authorized service center or other

qualified hydraulic tool service facility.

Table 2 - Cutter Troubleshooting Chart

Symptom

Possible Cause

Solution

Maint. Level

1. Blades move

slowly and/or have

difficulty cutting

the material.

Excessive cutting debris on the

blades.

Clean out debris.

Operator

Blocked or restricted hydraulic oil

flow.

Check for incomplete

hydraulic connections,

blocked hydraulic hoses or

other similar problems.

Operator

Low hydraulic oil level.

Check oil level. Add oil if low.

Operator

Material being cut is outside of

acceptable specifications.

Material properties must not

exceed stated maximum

limits. Refer to Section 2.1.

Operator

Blade wear.

Replace blades.

Service Center

Low hydraulic oil pressure or flow.

Check pump relief valve

setting. Troubleshoot and

repair pump and solenoid

control valve (as required).

Service Center

Cutter seal wear and/or internal

damage.

Repair cutter as required.

Service Center

2. Cutter vibrates

during operation.

Loose or missing screws or bolts.

Verify screws and bolts are

properly tightened. Replace

any missing screws or bolts.

Operator

3. External oil leaks.

Loose hydraulic fittings.

Tighten loose fittings.

Operator

Damaged hydraulic hoses.

Replace hoses.

Operator

Damaged hydraulic couplers.

Replace couplers.

Service Center

Worn or damaged cutter

components.

Repair cutter as required.

Service Center

Содержание EDCH130

Страница 15: ...Notes...

Страница 16: ...WWW ENERPAC COM...