9 Trouble-shooting

Proline Promass 83 FOUNDATION Fieldbus

80

Hauser

700

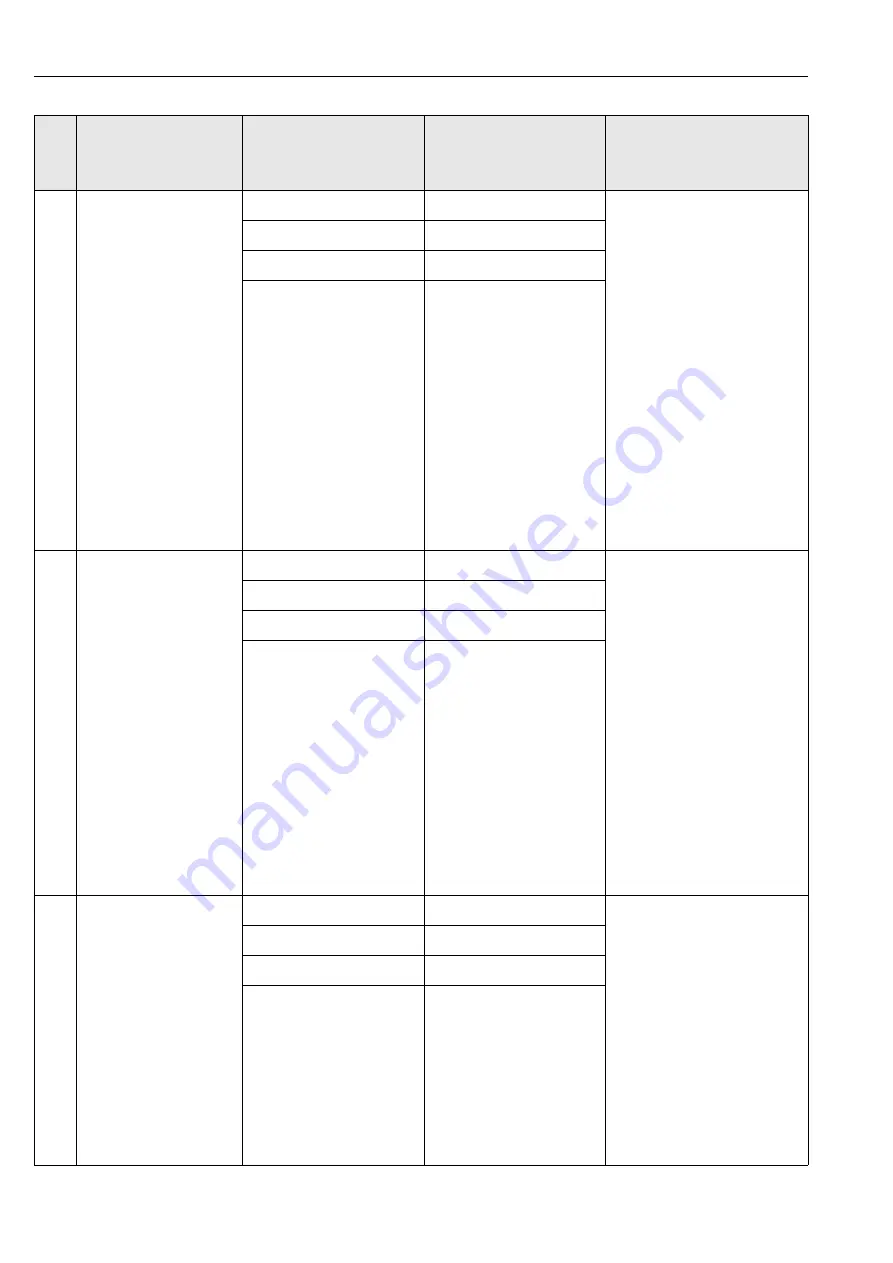

Device status message (FF):

Empty pipe detected –

Err. No. 700

Local display:

P

EMPTY PIPE

!

# 700

[.....] Quality = UNCERTAIN

OUT. QUALITY = UNCERTAIN

Cause:

The fluid density is outside the upper or

lower limit values set for the empty pipe

detection (EPD).

Causes:

– Air in the measuring tube

– Partly filled measuring tube

Remedy:

1.

Ensure that there is no gas content

in the process liquid.

2.

Adapt the upper and lower limit

values for empty pipe detection to

the current process conditions.

– FF: Transducer Block

→

Para-

meter “EPD - Low Value” resp.

“EPD - High Value”

– Local display:

BASIC FUNCTIONS

→

PROCESS PARAMETER

→

EPD

PARAMETER

→

EPD VALUE

LOW resp. EPD VALUE HIGH

[.....] Substatus = Non specific

OUT. SUBSTATUS = Non specific

–

–

–

701

Device status message (FF):

Current of the measuring tube

to high – Err. No. 701

Local display:

P

EXC. CURR. LIM

!

# 701

[.....] Quality = UNCERTAIN

OUT. QUALITY = UNCERTAIN

Cause:

The maximum current value for the

measuring tube exciter coils has been

reached, since certain process fluid cha-

racteristics are extreme, e.g. high gas or

solid content.

The instrument continues to work

correctly.

Remedy:

In particular with outgassing fluids

and/or increased gas content, the follo-

wing measures are recommended to

increase system pressure:

1.

Install the instrument at the outlet

side of a pump.

2.

Install the instrument at the lowest

point of an ascending pipeline.

3.

Install a flow restriction, e.g. redu-

cer or orifice, downstream from the

instrument.

[.....] Substatus = Non specific

OUT. SUBSTATUS = Non specific

–

–

–

702

Device status message (FF):

Frequency control not stable

due the process fluid –

Err. No. 702

Local display:

P

FLUID INHOM.

!

# 702

[.....] Quality = UNCERTAIN

OUT. QUALITY = UNCERTAIN

Cause:

Frequency control is not stable, due to

inhomogeneous process fluid, e.g. gas

or solid content.

Remedy:

In particular with outgassing fluids

and/or increased gas content, the follo-

wing measures are recommended to

increase system pressure:

1.

Install the instrument at the outlet

side of a pump.

2.

Install the instrument at the lowest

point of an ascending pipeline.

3.

Install a flow restriction, e.g. redu-

cer or orifice, downstream from the

instrument

[.....] Substatus = Non specific

OUT. SUBSTATUS = Non specific

–

–

–

No.

Device status message FF

(Diag. - Act. Syst. Cond.)

Message on local display

Transducer block

Error messages

[.....] = process variable (e.g. mass

flow, volume flow, ...)

Analog Input Funct. Block

Error messages

Cause/remedy

Содержание Proline Promass 83

Страница 24: ...3 Installation Proline Promass 83 FOUNDATION Fieldbus 24 Endress Hauser ...

Страница 34: ...4 Wiring Proline Promass 83 FOUNDATION Fieldbus 34 Endress Hauser ...

Страница 64: ...6 Commissioning Proline Promass 83 FOUNDATION Fieldbus 64 Endress Hauser ...

Страница 66: ...7 Maintenance Proline Promass 83 FOUNDATION Fieldbus 66 Endress Hauser ...

Страница 90: ...9 Trouble shooting Proline Promass 83 FOUNDATION Fieldbus 90 Endress Hauser ...

Страница 116: ...Index Proline Promass 83 FOUNDATION Fieldbus 116 Endress Hauser ...

Страница 118: ...www endress com worldwide BA065D 06 en 12 04 50098623 FM SGML 6 0 ...