7

F

F

G

H

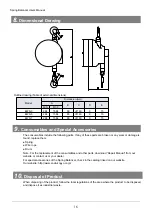

EWS-3

EWS-5

EWS-7

8.0

16.5

41.0

G

H

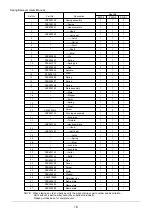

Model

1 pitch

J

EWS-3

EWS-5

EWS-7

3.0

2.7

11

Spring Balancer Repair Manual

Operating limit of the bottom hook

Model

Limiting dimension (mm)

Operating limit of the wire rope

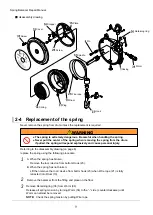

2-2-2 Inspection of the wire rope

See the figure below and measure the dimension of the wire rope. The wire rope must be replaced

when the dimension has reached the limiting dimension or the limiting number of broken wires

within one pitch. Stop using the balancer and change the wire rope (see “2-3 Replacement of the

wire rope”), or contact us or your dealer.

Dimension J (mm)

Reference

dimension

Limiting

dimension

Limiting number of broken wires

within one pitch

Check of the state of the wire rope

Check that there is no deformation or kink in the wire rope.

Note: Kink is the state in which the wire rope is partially

deformed due to torsion or looseness.

Kink

Deformation