17

OIL FOR SINGLE SCREW

COMPRESSORS

Due to the need for adequate lubrication, Vilter rec-

ommends only the use of Vilter lubricants, designed

specifically for Vilter compressors. With the extensive

research that has been performed, we are able to of-

fer specific lubricating oils. Use of oil not specified or

supplied by Vilter will void the compressor warranty.

Installation

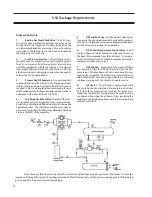

TESTING SYSTEM

FOR LEAKS

Vilter equipment is tested for leaks at the factory.

One the most important steps in putting the system

into operation is field testing for leaks. This must

be done to assure a tight system that will operate

without any appreciable loss of gas.

First, if test pressures exceed the settings of the

system, relief valves or safety devices, they must

be removed and the connection plugged during the

test. Secondly, all valves should be opened except

those leading to the atmosphere. Then, open all

solenoids and pressure regulators by the manual

lifting stems. All bypass arrangements must also

be opened.

HYDROCARBON SYSTEMS

“Oil pumped” dry nitrogen, or anhydrous CO

2

in

this order of preference may be used to raise the

pressure to the proper level for testing.

When the proper pressure is attained, test for leaks

with the soap mixture previously described. After

all leaks are found and marked, relieve the system

pressure and repair the leaks. Never attempt to

repair soldered or welded joints while the system is

under pressure. Soldered joints should be opened

and re soldered.

Do not simply add more solder to the leaking

joint. After all the joints have been repaired and the

system is considered “tight”.

Remove the drum and bring the pressure to the rec-

ommended test level with oil pumped dry nitrogen

or CO

2

. Then check the entire system again for leaks,

using a halide torch or electronic leak detector.

Be sure to check all flanged, welded, screwed and

soldered joints, all gasketed joints, and all parting

lines on castings. If any leaks are found, they must

be repaired and rechecked before the system can be

considered tight again, remembering that no repair

should be made to welded or soldered joins while

the system is under pressure.

Содержание VSG

Страница 1: ...1 VSG VSSG Single Screw Bare Shaft Compressor The World s Best Compressors For Gas Compression TM ...

Страница 2: ...2 ...

Страница 4: ...4 ...

Страница 56: ...56 ...

Страница 58: ...58 Gate Rotor ...

Страница 64: ...64 Main Rotor ...

Страница 66: ...66 Slide Valve Cross Shafts and End Plate ...

Страница 68: ...68 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly ...

Страница 72: ...72 Actuator Command Shaft ...

Страница 74: ...74 VSG Screw Compressor Miscellaneous Frame Components ...

Страница 78: ...78 Replacement Tools 291 1551 ...

Страница 82: ...82 Gaterotor Assembly ...

Страница 86: ...86 Main Rotor Slide Valve Cross Shafts End Plate Models VSG301 401 Counter Clockwise ONLY ...

Страница 88: ...88 Main Rotor Slide Valve Cross Shafts End Plate Models VSG501 701 Clockwise ONLY ...

Страница 92: ...92 Actuator Command Shaft ...

Страница 94: ...94 Model VSG 501 701 Model VSG 301 401 Miscellaneous Frame Components ...

Страница 96: ...96 Housing Accessories Miscellaneous Frame Components ...

Страница 99: ...99 ...