Instruction Manual

D103542X012

SS-263 Volume Booster

September 2019

9

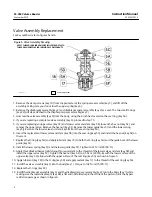

14. Apply lubricant (key 18) to the O-ring (4H) and the outside diameter of the spring seat (4F).

15. Install the upper spring (key 6) and the spring case assembly (key 3) on the upper diaphragm (key 4C).

CAUTION

To avoid damage to the diaphragms, do not overtighten the screws.

16. Replace the six cap screws (key 10) and tighten them in a crisscross manner using multiple patterns working up to a

final torque of 15.8 N•m (140 lbf•in).

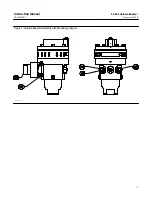

Parts Ordering

Whenever corresponding with your

about this equipment, mention the serial number of the valve

assembly. This serial number can be found on the actuator nameplate. It may also be helpful to mention the date and

other information on the volume booster nameplate as shown in figure 2.

When ordering replacement parts, state the complete eleven-digit part number of each part required as found in the

following parts list.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Automation Solutions should

not, under any circumstances, be used in any Fisher instrument, because they may void your warranty, might adversely

affect the performance of the valve, and could cause personal injury and property damage.