Instruction Manual

D103292X012

C1 Controllers and Transmitters

March 2017

19

change in the opposite direction than expected. For example, while moving the calibration adjuster to increase span, the output

pressure may decrease. This should be disregarded since even though the output pressure decreases, the span is increasing.

Proper controller response depends on nozzle-to-flapper alignment.

When performing span adjustments, carefully loosen both calibration adjuster screws while holding the calibration adjuster in

place. Then move the calibration adjuster slightly in the required direction by hand or using a screwdriver. Verify proper

nozzle-to-flapper alignment and hold the calibration adjuster in place while tightening both adjustment screws.

11. If the output pressure is not between 0.6 and 0.7 bar (8 and 10 psig), adjust the controller span by loosening the

12. Repeat steps 6 through 11 until no further adjustment is necessary.

13. For C1P and C1B controllers with anti-reset windup remove the two machine screws, anti-reset windup cover, and

14. Proceed to the Startup procedures for proportional-plus-reset controllers.

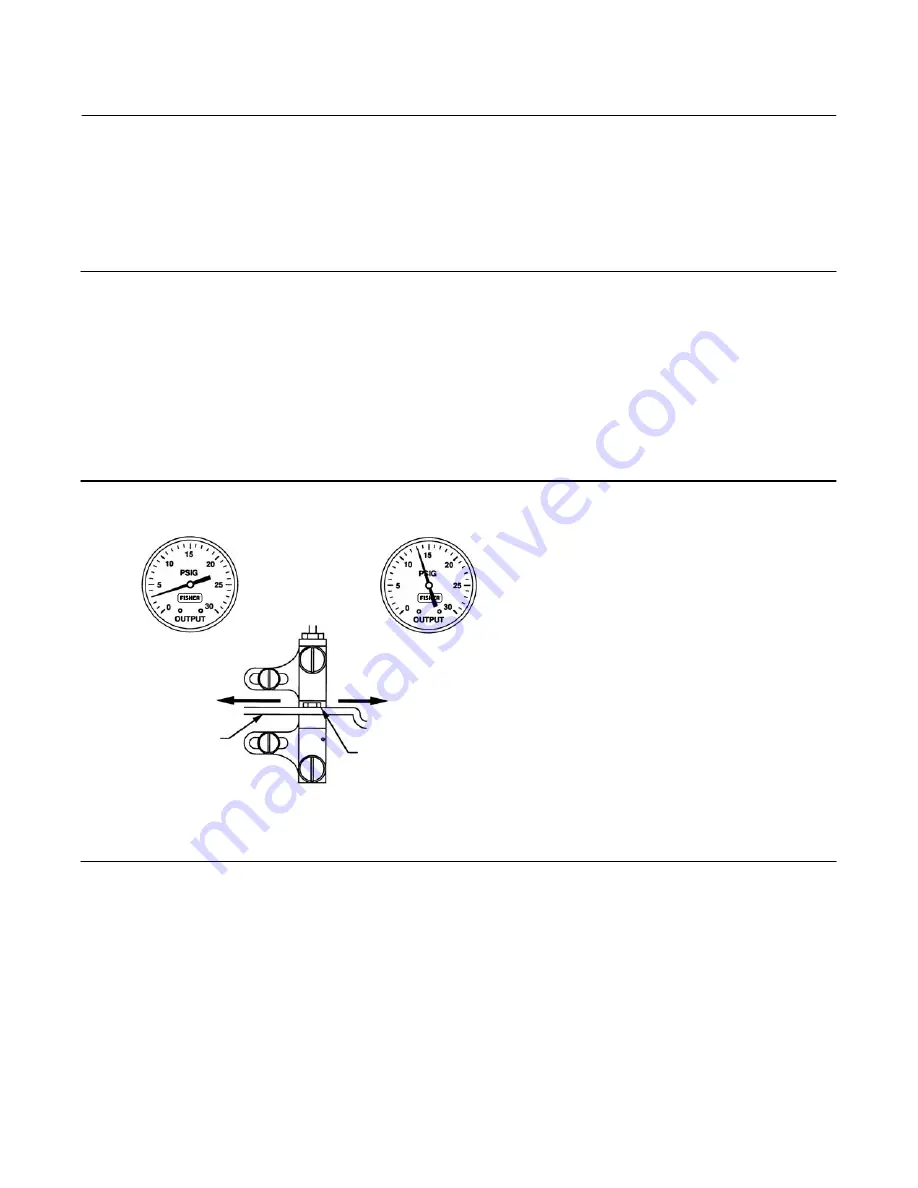

Figure 9. Direct-Acting Controller Span Adjustment —Proportional-Plus-Reset Controllers

IF OUTPUT IS:

BELOW

8 TO 10 PSIG

(0.6 TO 0.7 BAR)

ABOVE

8 TO 10 PSIG

(0.6 TO 0.7 BAR)

MOVE ADJUSTER

LEFT

MOVE ADJUSTER

RIGHT

FLAPPER

NOZZLE

NOTE:

3 TO 15 PSIG (0.2 TO 1.0 BAR) OUTPUT SHOWN.

FOR 6 TO 30 PSIG (0.4 TO 2.0 BAR) OUTPUT, ADJUST

VALUES AS APPROPRIATE.

A6154

Calibration: Anti-Reset Windup

Controllers with anti-reset windup have a differential relief valve assembly (figure 23). This relief valve is set at the

factory to relieve at a 0.3 bar (5 psi) pressure difference between the reset bellows pressure and the proportional

bellows pressure. The valve can be adjusted to relieve from 0.14 to 0.4 bar (2 to 7 psig).

The relief valve can relieve on either rising controller output pressure or falling controller output pressure. If the arrow

on the relief valve points toward the bottom of the controller case as shown in figure 23, the valve will relieve on falling

output pressure. If the arrow points in the opposite direction, the valve will relieve on rising output pressure. The valve

can be removed and reinstalled with the arrow pointing in the opposite direction to change the relief action.