Instruction Manual

D200149X012

3610J and 3620J Positioners

September 2017

40

1. Loosen the socket head screw (key 55) and remove the flexure adjustment (key 156) by carefully sliding it off the

end of the two flexures (on earlier positioners, a stick‐on label will have to be removed from the top flexure prior to

removing the flexure adjustment). For 3611JP or 3621JP positioners only, remove the two socket head screws and

lock washers (keys 180 and 181) and the parallel flexure (key 179) (not used on positioners for 585 size 100

actuators).

Note

Early 3611JP positioners do not have the parallel flexure described in step 1. The parallel flexure should be added if absent. This

may require a new summing beam assembly (key 123) and relay beam assembly (key 122) if these parts are not drilled and tapped

to accept the parallel flexure. See figure 25 for the location of the parallel flexure mounting screws.

2. Remove the range spring (key 150).

3. Relieve the tension on the zero spring (key 141) by rotating the zero adjustment screw (key 143) fully clockwise.

Remove the two screws (key 139) which retain the zero spring bracket (key 144). Remove the zero spring bracket,

the zero adjustment screw, and the spring seat (key 142). Remove the spring seat from the zero adjustment screw

by rotating the screw counterclockwise.

4. Unscrew the counter spring screw (key 127), and remove the counter spring seat (key 126) and the counter spring

(key 125).

CAUTION

Rotation of the diaphragm connector will damage the input diaphragms.

5. Remove the machine screw (key 140) while holding the hex diaphragm connector (key 135) with an open end

wrench to prevent rotation.

6. Remove the two summing beam mounting screws (key 124). Lift the summing beam assembly (key 123) from the

positioner case.

7. Remove the flapper (key 18) from the summing beam assembly by removing the flapper screw and washer (keys 51

and 176).

Disassembling the Nozzle Assembly

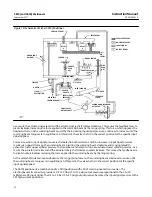

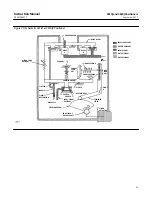

During the following nozzle assembly disassembly procedures, refer to figure 25 for key number locations.

1. Perform steps 1 through 5 of the Disassembling the Summing Beam Assembly procedure.

2. Unscrew the two captive machine screws (key 45) in the nozzle block (key 146) and remove the nozzle block.

Inspect the two O‐rings (key 64) and replace them if necessary. Apply lubricant (key 153) to the O‐rings before

replacement.

CAUTION

To avoid damage to the nozzle during the next step, be careful not to apply force to the exposed nozzle primary orifice.

Excess force may loosen or crack the orifice.

3. Remove the nozzle (key 116) from the nozzle block (key 146) by carefully pushing on the nozzle tip with the thumb

or other soft object until the base of the nozzle begins to protrude from the back of the nozzle block. Grasp the base