Instruction Manual

D200149X012

3610J and 3620J Positioners

September 2017

34

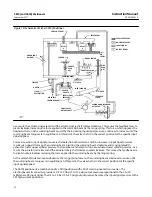

Figure 21. Schematic of Fisher 3611JP Positioner

38A8902‐B

B1846‐1

MINOR LOOP

GAIN ADJ

ZERO ADJ

RANGE SPRING

COARSE

SPAN

ADJ

CROSS‐OVER

ADJ

RELAY BEAM

RELAY

B

RELAY

A

SUPPLY PRESSURE

NOZZLE PRESSURE

INPUT SIGNAL

OUTPUT SIGNAL

OUTPUT SIGNAL

AIR SUPPLY

FINE

SPAN

ADJ

PIVOT B

INPUT MODULE

PIVOT A

FLAPPER

NOZZLE

FIXED

RESTRICTION

AIR SUPPLY

CAVITY A

CAVITY B

INPUT SIGNAL

PRESSURE

PISTON

ACTUATOR

SUMMING BEAM

COUNTER SPRING

FEEDBACK

LEVER

Maintenance

Positioner parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of

inspection and replacement depends upon the severity of service conditions. The following procedure describes

disassembly and reassembly of the positioner. When inspection or repairs are required, disassemble only those parts

necessary to accomplish the task. When reassembly is complete, make adjustments as described in the Calibration

section.

WARNING

Avoid personal injury or property damage from sudden release of process pressure. Before performing any maintenance

operations:

D

Always wear protective clothing, gloves, and eyewear when performing any maintenance operations to avoid personal

injury.