6. DETERMINE CABLE LENgTH

Cable length = pipe length × N + heat sink adjustments × N + slack × N

Slack = power supply (2') + tees (2' per tee) + tails (2' per tail)

N = number of traces

7. CABLE CONTROL

It is recommended that heating cables be controlled by a

thermostat to minimize energy consumption and provide appro-

priate temperature regulation of the pipe contents. Easy Heat

provides a full range of temperature control options, as follows:

ORDINARY AREAS

T4XA, Ambient sensing thermostat

– energizes cables when ambi

-

ent temperature falls below setting. Setting is adjustable from 15

to 140°F (-9.4 to 60°C). NeMA 4X enclosure. use for freeze

protection applications.

C4XC Line sensing thermostat

– energizes cables when line

(pipe) temperature falls below falls below 40°F (4°C). NeMA 4X

enclosure. Use for freeze protection and fuel line temperature

maintenance.

T4XC, Line sensing thermostat

– eenergizes cables when line

(pipe) temperature falls below setting. Setting is adjustable

from 25 to 325°F (-4 to 163°C). NeMA 4X enclosure. use for proc

-

ess control application, including grease lines.

HAzARDOUS LOCATIONS (CII, DIV. 2)

T9EA, Ambient sensing thermostat

– energizes cables when ambi

-

ent temperature falls below setting. Setting is adjustable from 15

to 140°F (-9.4 to 60°C). NeMA 4, 7 and 9 enclosure. use for freeze

protection applications.

T9EC, Line sensing thermostat

– energizes cables when line (pipe)

temperature falls below setting.

Setting is adjustable from 25 to 325°F (-4 to 163°C). NEmA 4, 7

and 9 enclosure. use for process control applications.

EXAMPLE

•

Straight water line (105') to be maintained at 50°F.

•

Minimum ambient temperature is -10°F.

•

Pipe is three-inch diameter steel.

•

Insulation is one inch thick mineral fiber.

•

Three valves

1. CALCULATE TEMPERATURE DIFFERENTIAL

∆T = TF-TA

∆T = 50-(-10)°F

∆T = 60°F

2. HEAT LOSS

Use

Table 1

to find heat loss. Where the desired temperature dif

-

ferential falls between two values, use interpolation:From

Table 1

:

@ 50°F Q = 4.4 w/ft.

@ 100°F Q = 9.2 w/ft.

QF = 4.4 w/ft + 10/50 × (9.2 - 4.4 w/ft.)

QF = 4.4 + .96 = 5.4 w/ft.

3. ADJUSTMENT TO HEAT LOSS

Adjust the heat loss for mineral fiber. From

Table 2

, the adjusment

factor is 1.2.

QM = QF × 1.2

QM = 5.4 w/ft. × 1.2

QM = 6.5 w/ft.

Since the piping is outdoors, no adjustment is necessary for the

absence of wind.

4. DETERMINE CABLE POWER

Select 8 w/ft cable. Apply single cable straight along the pipe.

5. ADJUSTMENT FOR HEAT SINKS

From

Table 3

, an additional 3 feet of cable is required at each

valve.

6. DETERMINE CABLE LENgTH

Length = 105 × 1 + 3 × 3 + Slack

Slack = 2 + 0 × 2 + 1 × 2 = 4

Total Length = 114 + 4 = 116'

7. SELECT ACCESSORIES

•

use line sensing control T4X6 with adjustable setting

set to 50°F.

•

Power connection kit adjustable setting set to 50°F.

•

Power connection kit

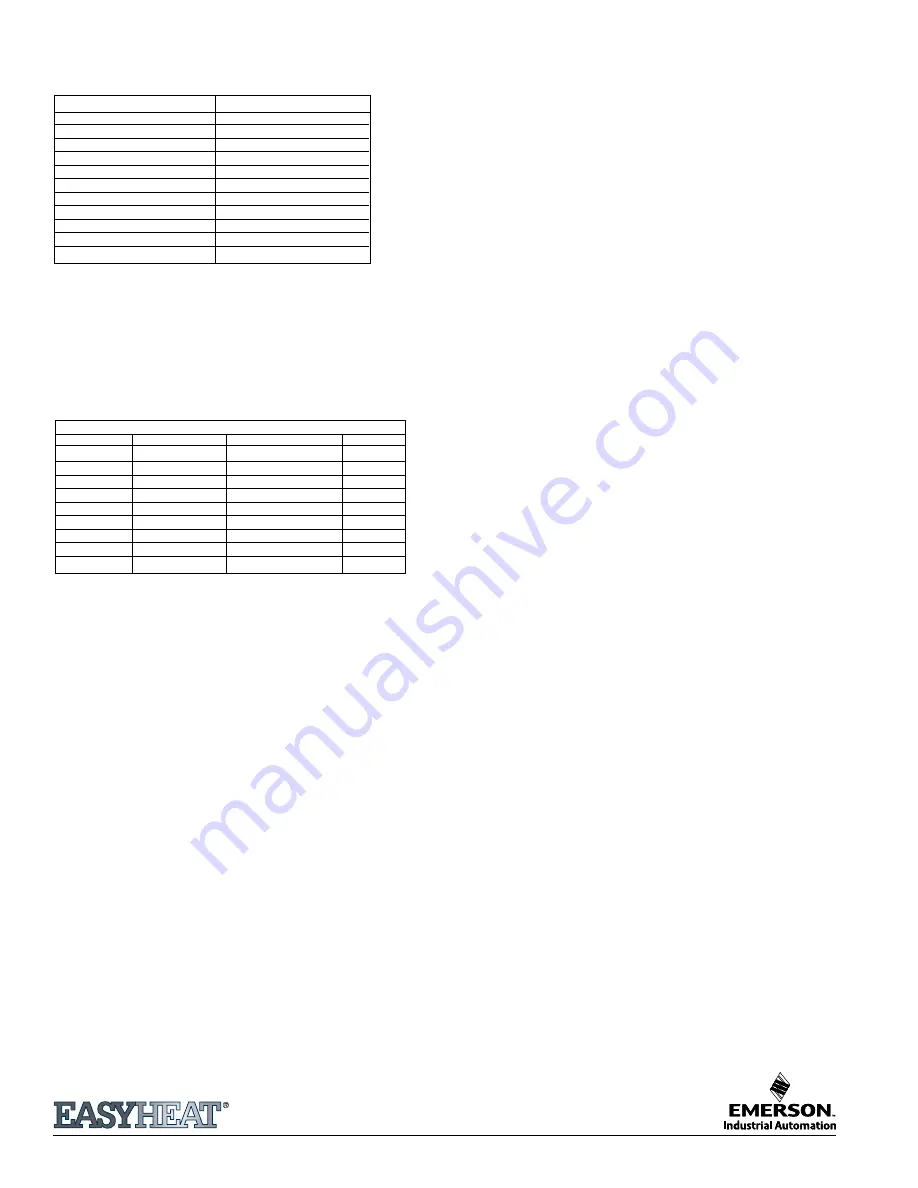

Table 2 – Insulation Factors

Insulation Type

Correction Factor

Glass Fiber

1.00

Calcium Silicate

1.72

Cellular Glass

1.84

Rigid Urethane

0.76

Foamed Elastomer

1.16

mineral Fiber

1.20

expanded Perlite

1.42

mineral Wool

1.04

Polystyrene

1.04

Flexible elastomer

1.16

Polyisocyanarate

0.68

5. ADJUSTMENTS FOR HEAT SINKS

Any thermally conductive item that protrudes through the insulation

will require extra heat to be applied to the pipe. The footage shown

in

Table 3

should be added to the required heater cable length

to compensate for these extra heat losses. When multiple-tracing

or spiraling cable, increase the cable adders proportionately.

Table 3 – Heat Loss Adder

Additional Heater Feet for Various Heat Sinks

Pipe Size

Flange

Pipe Support (1) Valve

.50

.5

1.0

1.0

.75

.5

1.5

1.5

1.00

.5

1.5

2.0

1.50

.5

1.5

2.5

2.00

.5

2.0

2.5

3.00

.75

2.0

3.0

4.00

.75

2.5

4.0

6.00

1.0

2.5

5.0

8.00

1.0

2.5

7.0

©2009 Easy Heat

www.easyheat.com