D7.8.4/0112-0415/E

16/17

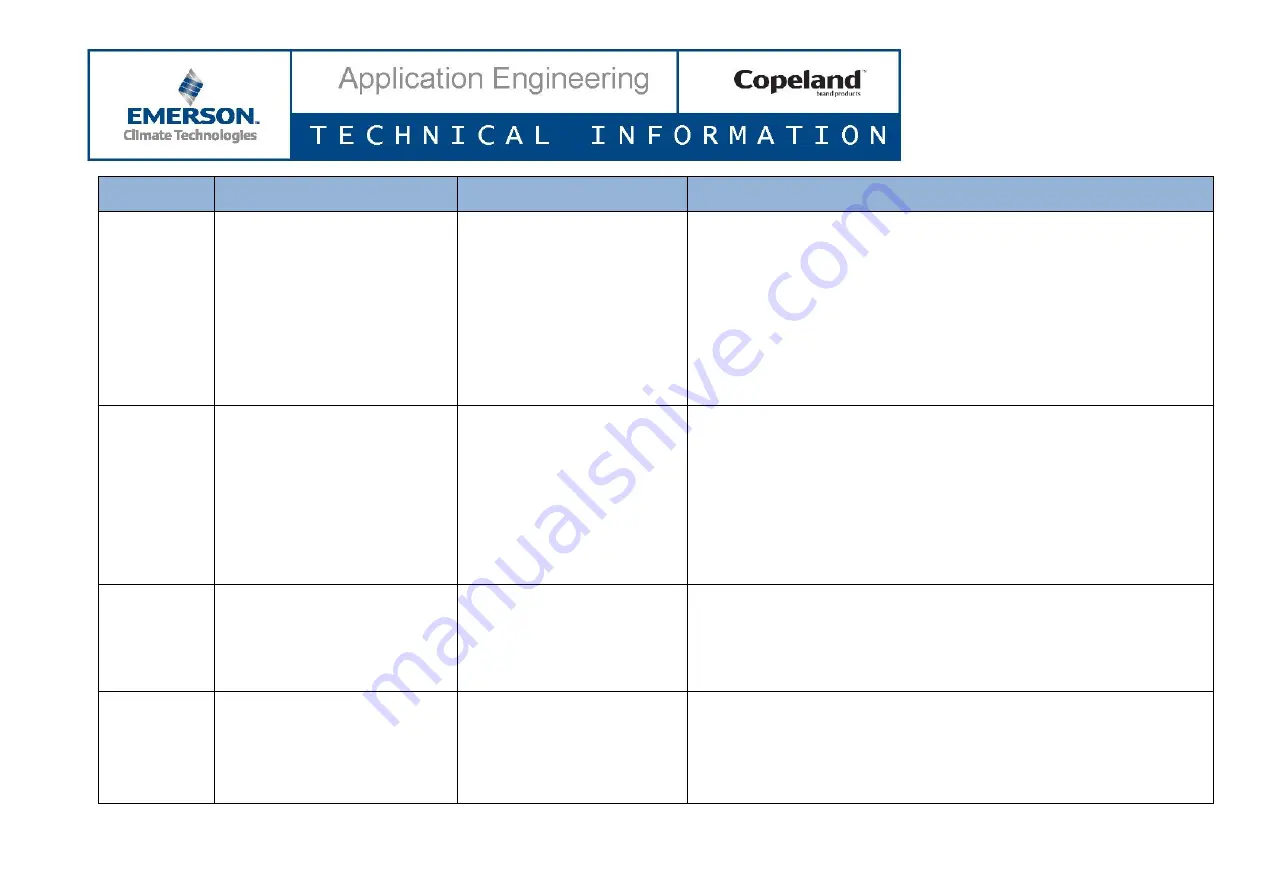

Flash

code

Alarm conditions

Possible failure reasons

Troubleshooting measures

4

Connection lost

between sensor

module

and

current sensor

Alert: Appears when the signal from

current sensor is not communicated

to the sensor module.

The current sensor is not

connected to the sensor

module.

Faulty current sensor.

Faulty sensor module.

Check if the CT connector is connected to the sensor module. If not connect the

4-pin current sensor connector into the sensor module.

Check if there is continuity between pin 3 & 4 (closest to the latch) of the current

sensing connector. The resistance should be less than 1

Ω. If the resistance is

greater than 1

Ω, replace the current sensing module. Be certain that the

receptacles are fully engaged in the connector block.

Check if the Amp and Volts values are correctly displayed. If not, inspect the

wire harness connector to ensure that the pins are fully engaged.

If the above-mentioned trouble shooting measures did not give positive results,

the reason is mis-installed connector or faulty sensor module. Replace the

faulty sensor module with new one.

5

Communication

error

Alert: Appears when there is no

communication

between

control

module and sensor module or pack

controller

Communication

between

CoreSense control module

and pack controller has been

lost.

Communication

between

CoreSense control module

and sensor module has been

lost.

Is there a communication network? If not, set the network dip-switch to "stand-

alone" and press reset.

Is there a communication network? If not, check that the communication

harness is engaged at both the CoreSense module and the sensor module.

If the LED on the top edge of the sensor module is dark, check 24 VAC power

to the sensor module, or replace the sensor module.

If communication network amber light is continuously on, reverse the

communication wire polarity. If voltage between centre pin and the right or left

pin is not 2.3-2.6 VDC, inspect for communication wire failure or wire strands

that are "shorting" between the wires or to ground.

6

Locked rotor

Trip: Appears when excessive current

is present in the compressor. Refer to

AE bulletin for more details.

Lockout:

Appears

when

10

consecutive locked rotor trip alarms

occur.

Motor rotor is mechanically

seized.

Excessive

current

present in the compressor.

Damaged valve plates in

cylinder head.

Check that motor voltage is adequate (± 10% of nominal rated voltage),

especially during the starting event.

Start compressor with no load. If it does start with no load, inspect the valve

plate(s) for damage or look for other causes of leak-back.

7

Missing phase

Trip: Appears when there is a missing

phase / single phasing.

Lockout:

Appears

when

10

consecutive

missing

phase

trip

alarms occur.

Loose wiring connections at

the

terminals

inside

compressor T-Box.

Worn out contactors.

Line break in one of the

phases.

Check voltage supply from the main power buss.

Check voltage into and out of contactor. Repair or replace contactor if

necessary.

Check that motor electrical connections are tight at the compressor motor

terminals.