17

U

B

0

f

B

Prohibited

range

EN

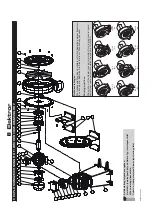

Operating and assembly instructions RDF

www.elektror.com

9016315 01.20/12

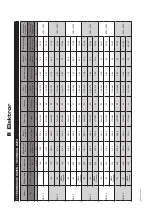

To ensure trouble-free operation of blowers and lateral

channel blowers, it is important that the converter meet

the following requirements:

• Converter output equal to or greater than motor power

output *)

• Converter current equal to or greater than motor current *)

• Converter output voltage equal to rated motor voltage

• Supply voltage max. 480V, including 5% voltage tolerance

• The pulse frequency of the converter should be 8 kHz,

since a lower pulse frequency can cause very noisy motor

operation.

•

The values for the maximum/minimum frequency can be

found at 1.13.

• The converter must have a connector for a temperature

sensor (PTC-sensor) or a temperature switch (normally

closed contact).

*) Refer to the rating plate for data

The motor can be operated in a delta or star-point con

fi

gu-

ration, depending on the input voltage of the converter.

It is absolutely mandatory to set the converter to the fol-

lowing U/f relation.

f

B

and U

B

= refer to rating plate

If this is ignored, the motor current will increase dispropor-

tionately and the drive motor will fail to achieve its rated

speed.

Warning!

To avoid personal damage, destruction of the

blower or motor overload, a higher frequency

(speed) than the frequency (f

B

) speci

fi

ed on the

rating plate must never be set on the converter

otherwise the motor may be overloaded or the

blower destroyed due to the increased speed. The

temperature sensors are connected to the corre-

sponding converter inputs to protective the drive

motor. Single-phase alternating current motors

are not suitable for converter operation.

It is absolutely essential that you observe the

installation and safety instructions described in

the respective operating or application manuals

provided by the frequency converter supplier to

guarantee a safe and trouble-free operation.

It is also important to note that special ambient

conditions may lead to a high level of contamina-

tion of the cooling

fi

ns with the FUK devices. The

frequency converter switches o

ff

if the cool-

ing output on the cooling

fi

ns is not adequate.

Regular cleaning is required for devices in these

environments.

Note!

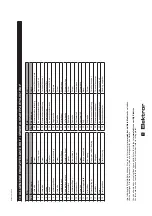

The following times apply for the respective

device motor output class (see rating plate) with

run-up/expiry as well as speed changes in order

to to avoid high component loads and faults in

the converter operation:

Device motor output

Run-up time

[s]

Expiry time

[s]

Motor output < 0.25 kW

5

10

0.25 kW < Motor output

<=3.0 kW

10

20

3.1 kW < Motor output

<= 7.5 kW

20

40

7,6 kW < Motor output

<= 11.0 kW

30

60

11,1 kW < Motor output

<= 30.0 kW

30

100

A uniform run-up and expiry must be guaranteed within the

run-up and expiry times.

No speed changes must occur during operation that exceed

the speed change during run-up and expiry.

Protection by residual-current-operated circuit breaker

(FI circuit-breaker):

The present IGBT frequency converters produce discharge

currents of >=3.5 mA due to their design principle. These dis-

charge currents can lead to unwanted tripping in systems

protected by a 30 mA-FI circuit-breaker.

If a fault occurs, fault currents can also discharge through the

PE conductor as direct current. If protection is needed on the

supply side by means of an FI circuit-breaker, then an ACDC

sensitive (type B) FI circuit-breaker must be used. Use of an

FI circuit-breaker other than type B can cause death or seri-

ous injury if a fault occurs. To meet the EN 61800-5-1 stand-

ard, the PE conductor must be duplexed and routed through

separate terminals or have a cross-section of at least 10 mm²

Cu.

Operation and connection to public grids:

See 3.5

4.3 Hydraulic Motor Operation

The run-up and expiry times as well as the speed changes

speci

fi

ed in 4.2 should be noted when operating with hydrau-

lic motors. Free-running hydraulic motors should be used to

guarantee a smooth run on.

5 INSTRUCTIONS FOR MAINTENANCE

Wearing parts are subject to the recommended maintenance

intervals (refer to 5.1 to 5.6). The service life of wearing parts

(ball bearings and

fi

lters) depends on the operating hours,

the load and other in

fl

uences, such as temperature, etc.

Maintenance and servicing may only be performed by per-

sons with the necessary expertise and regular training. In ad-

dition to the appliance’s operating instructions and the regu-

lations and recommendations for the system as a whole, the

following points should be observed:

Inspection and maintenance intervals:

The operator must set the cleaning, inspection and mainte-

nance intervals himself according to operating hours, load

and operating conditions.

Immediate inspection and maintenance

The blower must be inspected immediately if vibrations or

reduced air

fl

ow are observed.

Содержание RD 14 F

Страница 11: ...11 www elektror de Betriebs und Montageanleitung RD F 9016315 01 20 12 DE ...

Страница 26: ...26 9016315 01 20 12 ...

Страница 27: ...27 9016315 01 20 12 ...