© EA Elektro-Automatik in 2022, this information is subject to change without notice

62

06230920_manual_ps_10000_3u_15kw_en_01

3.7

Locking the control panel (HMI)

In order to avoid the accidental alteration of a value during manual operation the rotary knobs or the touchscreen can be

locked so that no alteration of values will be accepted without prior unlocking.

►

How to lock the HMI

1.

In the main page, tap the lock symbol

(upper right corner).

2.

The

Lock

screen will appear where you can select to lock the HMI completely or with the exception of the button

On/

Off

by enabling

On/Off possible during HMI lock

. Additionally, you can decide to activate the additional

PIN for user

interface lock

. The device would later request to enter this PIN every time you want to unlock the HMI.

3.

Activate the lock with

Start

. The device will jump back to the main screen and dim it.

If an attempt is made to tap the screen or rotate a knob whilst the HMI is locked, a requester appears in the display asking if

the lock should be disabled.

►

How to unlock the HMI

1.

Tap any area on the touchscreen or rotate any knob or press the button On/Off (only in full lock).

2.

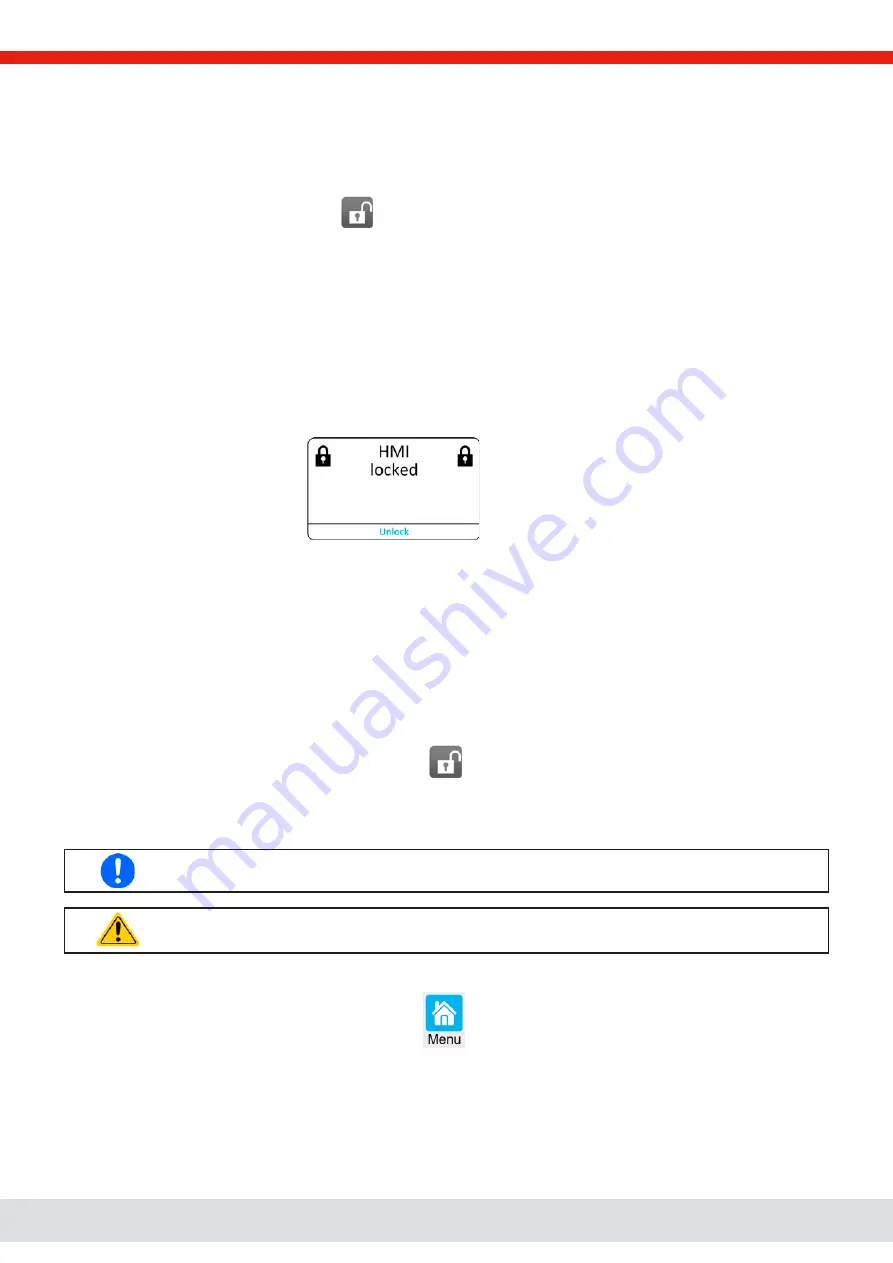

This request pop-up will appear:

.

3.

Unlock the HMI by tapping on

Unlock

within 5 seconds, otherwise the pop-up will disappear and the HMI remains locked.

In case the additional PIN code lock

has been activated in the

Lock

screen, another requester will pop up, asking you

to enter the PIN before it finally unlocks the HMI.

3.8

Locking the adjustment limits and user profiles

In order to avoid the alteration of the adjustment limits (also see

“3.4.4. Adjustment limits“) by an unprivileged user, the screen

with the adjustment limit settings (

Limits

) can be locked by a PIN code. This will lock group

Limits

in the

Settings

menu and

menu

Profiles

until the lock is removed by entering the correct PIN or, in case it has been forgotten, by resetting the device

to factory default.

►

How to lock the Limits and Profiles

1.

While the DC output is switched off, tap touch area

on the main screen. In case the HMI is locked, it has to be

unlocked first, probably by entering the PIN. After this, menu page

Lock

will be entered.

2.

In the switch next to

Lock limits and profiles with user PIN

.

3.

Leave the

Settings

menu.

The same PIN as for the HMI lock is used here. It should be set before activating the Limits lock. See “3.7.

Locking the control panel (HMI)“

Be careful to enable the lock if you are unsure what PIN is currently set. In doubt use ESC to exit the

menu page. In menu page Lock you can define a different PIN, but not without entering the old one.

►

How to unlock the Limits and Profiles

1.

While the DC output is switched off, tap touch area

on the main screen.

2.

In the menu tap on

HMI setup

, then on group

Lock

.

3.

In the group tap on

Unlock limits and profiles

. You will be requested to enter the 4-digit PIN.

4.

Deactivate the lock by entering the correct PIN.