19

D.3.1 HACCP CONNECTIONS

Refer to the handbook enclosed with the kit for instructions

on installing the accessories.

Basic system connection

The printer can provide a print-out of data collected by the probe

connected to the electronic board. To do this, connect the se-

rial cable (shielded) to the printer and the appliance itself. The

serial cable connector is located behind the control panel.

Set the print interval (see

TPRN

parameter); and specify the

type of report by setting the

“PRND”

parameter.

REPORT PRINT-OUTS

Report print-outs are produced automatically when the appli-

ance is switched on.

The print-out contains data measured by electronic the board

and indicates:

- the date and time of start-up, repeated every 20 lines of tem-

perature;

- the chamber temperature at pre-set intervals (TPRN user

parameter);

- the description of the type of alarm generated complete

with the exact time of the start and end of the alarm;

- time of the start and end of defrosting.

D.4.1 QUICK TROUBLESHOOTING GUIDE

In some cases faults can be remedied easily and quickly. Below

there is a list of possible faults and remedies:

A.

The appliance doesn’t switch on:

- check that the main circuit breaker is powered.

B.

The appliance does not reach the set internal temperature:

- check that the condenser is clean;

- check that the cycles have been set properly;

- check that the product has been loaded properly into

the chamber;

C.

The appliance is excessively noisy:

- check that the appliance is properly levelled.

If it is unbalanced this could cause vibrations.

- check that the cabinet is not touching other units, as this may

cause resonant vibrations.

If the defect persists after having carried out the above checks,

contact the service center, remembering to give the following

details:

• the nature of the fault;

• the appliance’s PNC (production number code);

• the Ser. No. (appliance serial number).

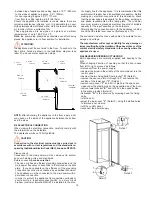

Note:

the data plate with all the appliance specifications is

located on the refrigeration unit compartment at the top right

hand side. There is also a plate bearing the appliance’s PNC

code and serial number located underneath the logo.

These

are essential for identifying the type of appliance and date of

manufacture.

D.3 HACCP CONNECTIONS

(ACCESSORIES)

PNC 726377

Ser.No. 44600010

D.4 TROUBLESHOOTING

Example: PNC 726377 00 - Ser.No. 44600010

726377 00: Prostore Smart

44600010: manufactured in 2004, week 46, 10th item.

D.5.1 WASTE STORAGE

At the end of the appliance’s working life, make sure it is dis-

posed of properly. Make sure you remove the doors before

scrapping the appliance.

Special waste materials can be stored temporarily while await-

ing processing for disposal and/or permanent disposal. In

any event, the binding environmental protection laws in the

country of use must be observed.

D.5.2 PROCEDURE FOR PRELIMINARY DISMANTLING

OF THE APPLIANCE

All countries have different legislation; provisions laid down by

the laws and the authorized bodies of the countries where

demolition takes place are therefore to be observed.

In general terms, the refrigerator must be taken to a special-

ized collection/demolition center.

Dismantle the refrigerator and group the components together

according to their chemical characteristics (plastic parts are

marked with letters identifying the material). Bear in mind that

the compressor contains lubricant oil and coolant, which can

be recycled, and that the refrigerator components are classed

as special waste that cannot be disposed of as urban waste.

Make the appliance unusable by cutting off the power supply

cable and removing the door and or locking mechanisms in

order to avoid the risk of anyone becoming trapped inside.

DISMANTLING OPERATIONS MUST BE CARRIED OUT BY

QUALIFIED PERSONNEL.

• Set of test and inspection documents

• Wiring diagram

• Installation diagram

D.6 ENCLOSED DOCUMENTS

D.5 WASTE DISPOSAL AND DEMOLITION