ENGLISH

7

B4

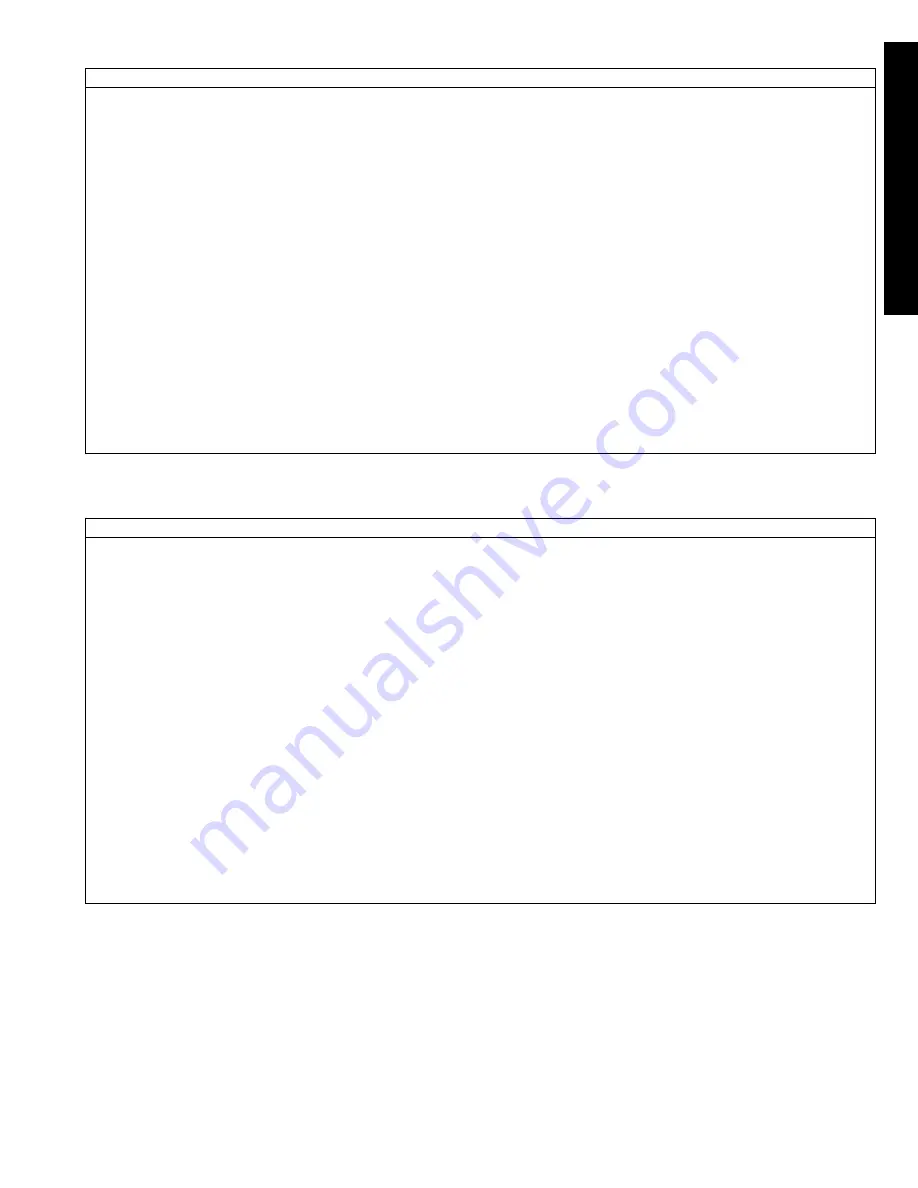

TECHNICAL DATA

Table 2

Standard cycle time may vary should the inlet water temperature be different from that indicated above.

MODEL

WT830M/PW1M

WT830H/PW1MH

WT850M/PW2M

Supply voltage:

208 V, 3 ph, 60 Hz 45 amp

208 V, 3 ph, 60 Hz 45 amp

208 V, 3 ph, 60 Hz 56 amp

Total Watts

14.8 kW

14.8 kW

17.5 kW

Boiler heating elements

12.0 kW

12.0 kW

12.0 kW

Tank heating elements

12.0 kW

12.0 kW

12.0 kW

Water supply pressure

7.25 - 101 psi/50 - 700 kPa

7.25 - 101 psi/50 - 700 kPa

7.25 - 101 psi/50 - 700k Pa

Water supply temperature

122°F/50°C

122°F/50°C

122°F/50°C

Water supply hardness

140 ppm/14°fH max

140 ppm/14°fH max

140 ppm/14°fH max

Rinse cycle water consumption

1.6 gallons/6.2 liters

1.6 gallons/6.2 liters

3.2 gallons/12 liters

Boiler capacity

4.8 gallons/18 liters

4.8 gallons/18 liters

4.8 gallons/18 liters

Tank capacity

25.1 gallons/95 liters

25.1 gallons/95 liters

39.6 gallons/150 liters

Standard cycle time with water supply at

122°F/50°C

360/600/900 seconds

360/600/900 seconds

360/600/900 seconds

Legal noise level Leq

<70 dB

<70 dB

<70 dB

Minimum Supply - Circuit Ampacity

48 amp

48 amp

62 amp

Net weight

441 lb/200 kg

476 lb/216 kg

661 lb/300 kg

Shipping weight

606 lb/275 kg

628 lb/285 kg

849 lb/385 kg

Shipping width

44 1/16“ / 1120 mm

44 1/16“ / 1120 mm

70 7/8“ / 1800 mm

Shipping height

86 5/8“ / 2200 mm

94 1/2“ / 2400 mm

86 5/8“ / 2200 mm

Shipping depth

43 5/16“ /1100 mm

43 5/16“ /1100 mm

43 5/16“ /1100 mm

Table 1

MODEL

WT830M/PW1M

WT830H/PW1MH

WT850M/PW2M

Supply voltage:

240 V, 3 ph, 60 Hz 39 amp

240 V, 3 ph, 60 Hz 39 amp

240 V, 3 ph, 60 Hz 49 amp

Total Watts

14.8 kW

14.8 kW

17.5 kW

Boiler heating elements

12.0 kW

12.0 kW

12.0 kW

Tank heating elements

12.0 kW

12.0 kW

12.0 kW

Water supply pressure

7.25 - 101 psi/50 - 700 kPa

7.25 - 101 psi/50 - 700 kPa

7.25 - 101 psi/50 - 700k Pa

Water supply temperature

122°F/50°C

122°F/50°C

122°F/50°C

Water supply hardness

140 ppm/14°fH max

140 ppm/14°fH max

140 ppm/14°fH max

Rinse cycle water consumption

1.6 gallons/6.2 liters

1.6 gallons/6.2 liters

3.2 gallons/12 liters

Boiler capacity

4.8 gallons/18 liters

4.8 gallons/18 liters

4.8 gallons/18 liters

Tank capacity

25.1 gallons/95 liters

25.1 gallons/95 liters

39.6 gallons/150 liters

Standard cycle time with water supply at

122°F/50°C

360/600/900 seconds

360/600/900 seconds

360/600/900 seconds

Legal noise level Leq

<70 dB

<70 dB

<70 dB

Minimum Supply - Circuit Ampacity

41 amp

41 amp

54 amp

Net weight

441 lb/200 kg

476 lb/216 kg

661 lb/300 kg

Shipping weight

606 lb/275 kg

628 lb/285 kg

849 lb/385 kg

Shipping width

44 1/16“ / 1120 mm

44 1/16“ / 1120 mm

70 7/8“ / 1800 mm

Shipping height

86 5/8“ / 2200 mm

94 1/2“ / 2400 mm

86 5/8“ / 2200 mm

Shipping depth

43 5/16“ /1100 mm

43 5/16“ /1100 mm

43 5/16“ /1100 mm