Mechanical Operation and Maintenance Manual for ER20-1100 Industrial Robot

34

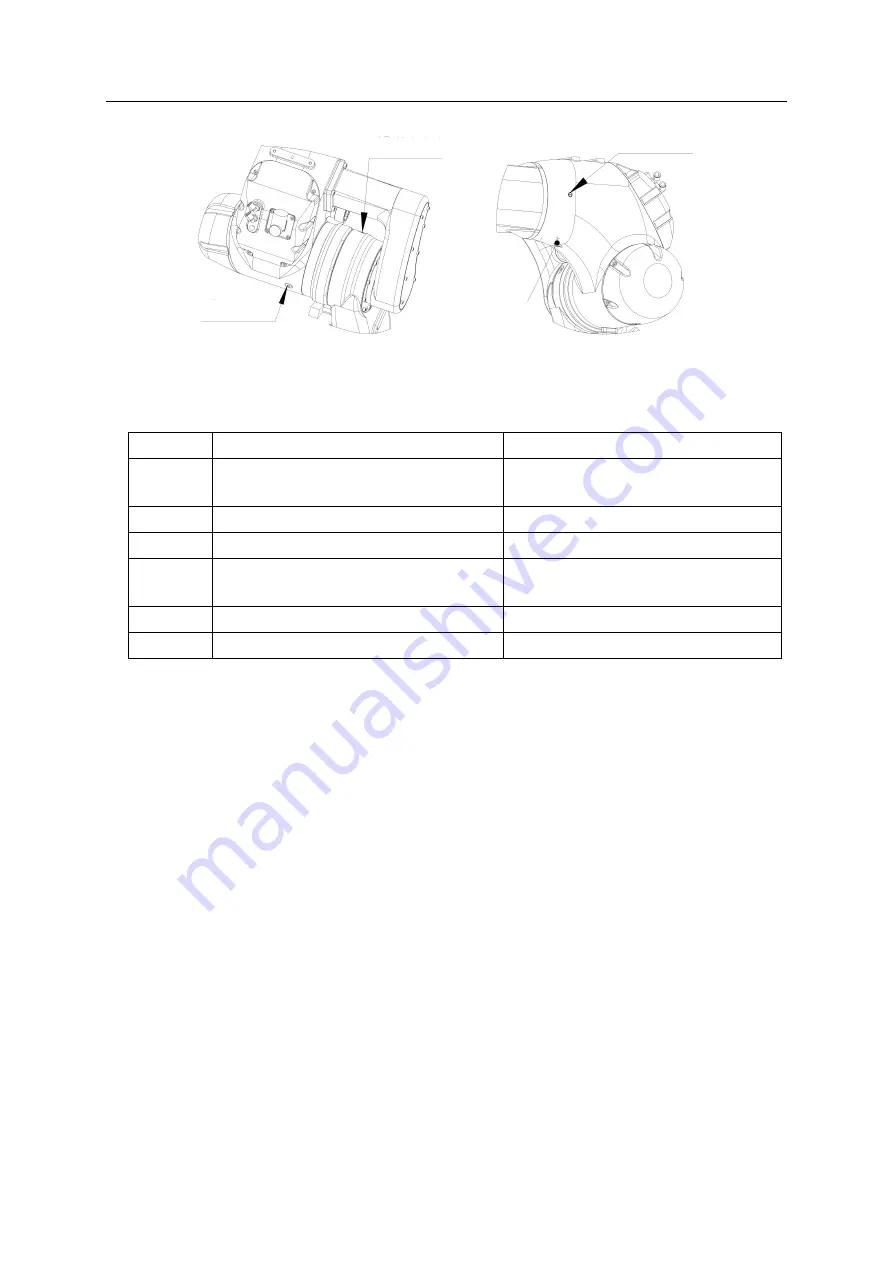

Figure 4-1 Distribution on robot of intake and outlet of lubricant

Table 4-8 Tools required for lubricant replacing

Number

Specification

Remark

1

Lubricant injector

Has the function of measuring the capacity of

lubricant to be injected

2

Injector joint

1 PC

3

Hose

1 PC

4

Poid meter

Measuring the capacity of lubricant that had

been injected

5

Sealing tape

/

6

Air source

/

4.3.4 Release the residue pressure in lubricant cavity

The robot need to be operated properly for releasing the residue pressure in the lubricant

cavity after injection. To avoid the lubricant splashing, a recyclable bag should be installed

beneath the intake and outlet of lubricant.

To release the residue pressure, those axes included J1, J2, J3, J4 and J6 should be kept

on low-speed motion for more than 20 minutes, with the respective axis azimuth is ±30°, ±5°,

±5°, ±30°,±30°.

If the residue pressure releasing motion can not be performed due to surrounding

situations, the robot should be operated equivalently (For example, half the axis azimuth,

and twice the motion time). When the motion was completed, seal the lubricant outlet (with

combination washer or with binding sealing tape).

4.4 Maintenance of timing belt

Because the J5 and J6 axes are both driven by timing belt, operation for a period of time

may cause loosening and decline of performance precision. The timing belt may also be worn

and cracked. If it is not replaced and maintained, transmission failure and economic loss may

occur. Therefore, it is recommended to check the running state of the timing belt regularly

(every half year). The loosening part should be tightened and the damaged should be replaced

Lubricant outlet of axis J3

Lubricant intake of axis J3

Lubricant outlet of axis J4

Lubricant intake

of axis J3