9

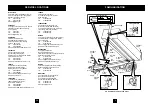

CONTROLS

16

Dirty oil is the enemy of a hydraulic system. The cleaner the oil, the more

efficient the hoist's operation and the longer it's life. So always use clean

hydraulic oil for topping up or changing the oil in the tank.

Use oil to specification ISO6734/4 HM32 for temperatures between

-20°C to +30°C. Typical suitable trade names are:

CASTROL

AWS32

ESSO

VG32

GULF

HYDRASIL 32

MOBIL

DTE24

SHELL

TELLUS 32

For other climates seek advice from your local distributor or direct from

Edbro.

Never put used oil in the tank.

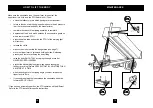

To determine the oil level, remove the filler cap and check that the level

is within the max./min. marks as shown:

OIL

Correct oil level:

- not above green mark on dipstick

- not below red mark on dipstick

Edbro combined filler/breather

assembly

GREEN

RED

Max.

Level

Min.

Level

If the hoist judders in 'LOWER', or the tubes operate out of sequence

when lowering, there may be air in the system. For early cylinders

without a bleed screw ( approxiamately, serial numbers before

LG017000 / LH002100) bleed the system as follows:

•

loosen the pressure outlet hose from the pump a little

BLEEDING THE SYSTEM

PTO engaged

warning light

PTO switch

Fig. a. Combined PTO & tipper air controls

Fig. b. Separate tipper air control

Tipper lever with

spring return

safety feature