B

LB 1681

Max Gas 170 PR - 250 PR

pag.12

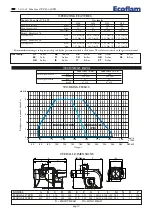

NOTE:

should it be difficult to measure the quantity of delivered litres of gas, due to the particular meter’s dial, it is

possible to repeat, sequentially, the above steps many times, so as to reach a significant amount of gas volume. In such a

case, the thermal power at the ignition shall be obtained by multiplying the ratio, between the amount of delivered

litres and the number of cumulated safety times (i.e. the value of the safety time multiplied by the number of ignitions)

by the F factor. See the following examples: Example A: MAX GAS 170 burner, nat. gas; rated thermal power of 175

kW; safety time of 3 secs; a sequence of 4 ignitions is made, for a total amount of 41 delivered litres. The thermal

power at the ignition, in kW, shall be: 41/(3x4)x34,02 = 116 kW and therefore correct, being smaller than 120 kW.

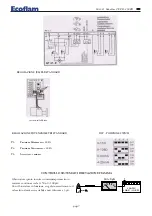

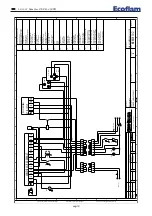

(LANDIS & STAEFA LGB 21/LGB 22) UP CYCLE

Thermostat

motor

Transformer

Gas valve

Flame

‡ 30 s

0,5 s

3 s

Air pressure switch

Necessary input signal

output signal of the device

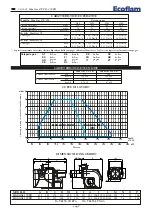

To calculate the burner’s working output, in kW, proceed as follows:

- Check at the meter the quantity of supplied litres and the duration, in seconds, of the

reading, then calculate the burner’s output through the following formula:

CALCULATION OF WORKING OUTPUT OF THE BURNER

e x f = kW

s

e

=

Litres of gas

s

=

Time in seconds

G20 = 34,02

G25 = 29,25

G30 = 116

G31 = 88

f

+

-

0

1

2

3

4

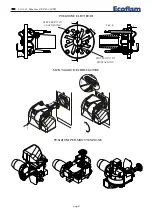

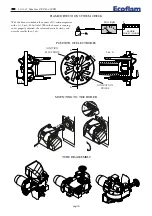

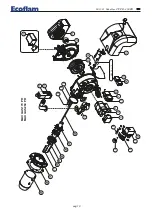

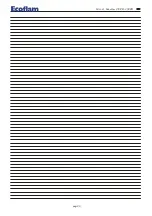

SETTING THE FIRING HEAD

ADJUSTING THE AIR PRESSURE SWITCH

The air pressure switch must be adjusted so that an insufficient air flow does not allow

the CO value to exceed 1% in volume. After having adjusted the gas flow and obtained

optimum combustion (CO

2

= 9.5 to 9.8% and a CO value of less than 75 ppm), the air

pressure switch must be adjusted. Remove the cover with the burner operating, cover the

air intake progressively with a piece of cardboard to obtain a value of CO

2

= 10.8 (G20-

G25)> 13 (G30-G31) and a CO value of less than 5,000 ppm. Adjust the air pressure

switch until the burner shuts down. Remove the cardboard from the air intake and start

up the burner again. Replace the cover.

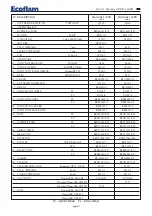

ADJUSTING THE GAS PRESSURE SWITCH

Adjust the pressure switch to 50% of the rated pressure of the gas used.

RARED PRESSURE:

G 20 = 20 mbar G 25 = 25 mbar

G 30 = 29 mbar G 31 = 37 mbar

0,4

0,6

0,9

3,0

1

,5

2,1

1,8

2,4

2,7

1,

2

A

B

2,5

5

10

15

50

2

5

35

30

40

45

20

C

D