Air Source Heat Pump EAP range user manual - www.ecoairpump.co.uk

Do not use any cleaning agents containing sand, soda, acid or chloride as these may damage the surface.

To prevent malfunctions in the heat exchanger of the heat pump caused by dirt deposits, care must be taken that the heat

exchanger in the heating installation cannot become contaminated. In the event that operating malfunctions due to contamination

occur nevertheless, the system should be cleaned as described below.

8.2. Cleaning of Heating Side

The ingress of oxygen into the heating water may result in the formation of oxidation products. An additional contamination of the

heating water caused by residues of lubricating and sealing agents occurs in many cases.

Both of the above causes may lead to a reduction in the performance of the heat pump condenser. In these cases the installer

needs to clean the condenser. Based on information known to date we recommend cleaning with a 5% phosphoric acid solution or,

in the case that cleaning needs to be performed more frequently, with a 5% formic acid solution. In either case, the cleaning fluid

should be at room temperature. Thorough flushing is necessary to ensure that all cleaning agent residues are removed from the

system. It is recommended that the heat exchanger is cleaned in the direction opposite to the normal flow direction. Owing to their

acid content flushing agents must be used with caution. To prevent acidic flushing agents from entering the heating installation

when cleaning the condenser, we recommend that the flushing device be mounted directly to the supply and return line of the heat

pump.

To prevent consequential damage it is imperative that the water circuit be neutralized after cleaning using appropriate

agents.

8.3. Cleaning of Air Side

Evaporator, fan and condensate drain should be cleaned of debris (leaves, branches, etc.) from time to time.

When cleaning do not use any sharp or hard objects so as to prevent any damage to the evaporator and the condensate pan.

9. MALFUNCTIONS /TROUBLESHOOTING

This heat pump is a quality product and is designed for troublefree and maintenance-free operation. In the event that a malfunction

occurs nevertheless, you will be able to correct the problem easily yourself in the majority of cases. Simply consult the Malfunctions

and Troubleshooting table in the operating manual of the controller. Malfunctions can be interrogated at the heat pump controller. If

the problem cannot be corrected by the user, please contact the after-sales service in charge.

Any work on the heat pump may

only be performed by authorized and qualified after-sales service technicians.

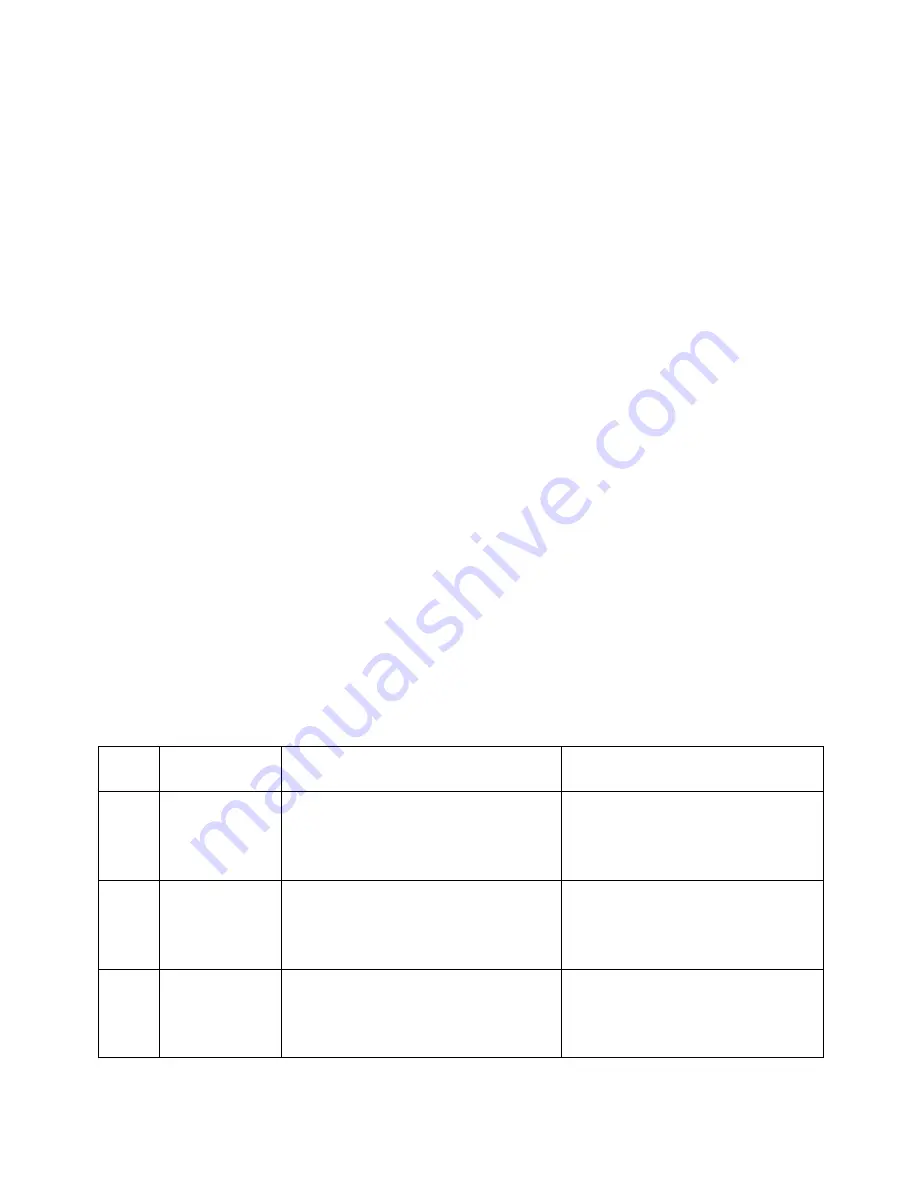

Error

Code

Description

Possible Reason

Solution

E1

Inlet Water

Temperature

Sensor

Malfunction

1) The inlet water temperature sensor is

damaged

replace the sensor

E2

Evaporator Coil

Temperature

Sensor

Malfunction

1) The evaporator coil temperature sensor

is damaged

replace the sensor

E3

Ambient Air

Temperature

Sensor

Malfunction

1) The ambient air temperature sensor is

damaged

replace the sensor