10

FLS

Platinum

Instruction Manual

FLS Platinum Operating

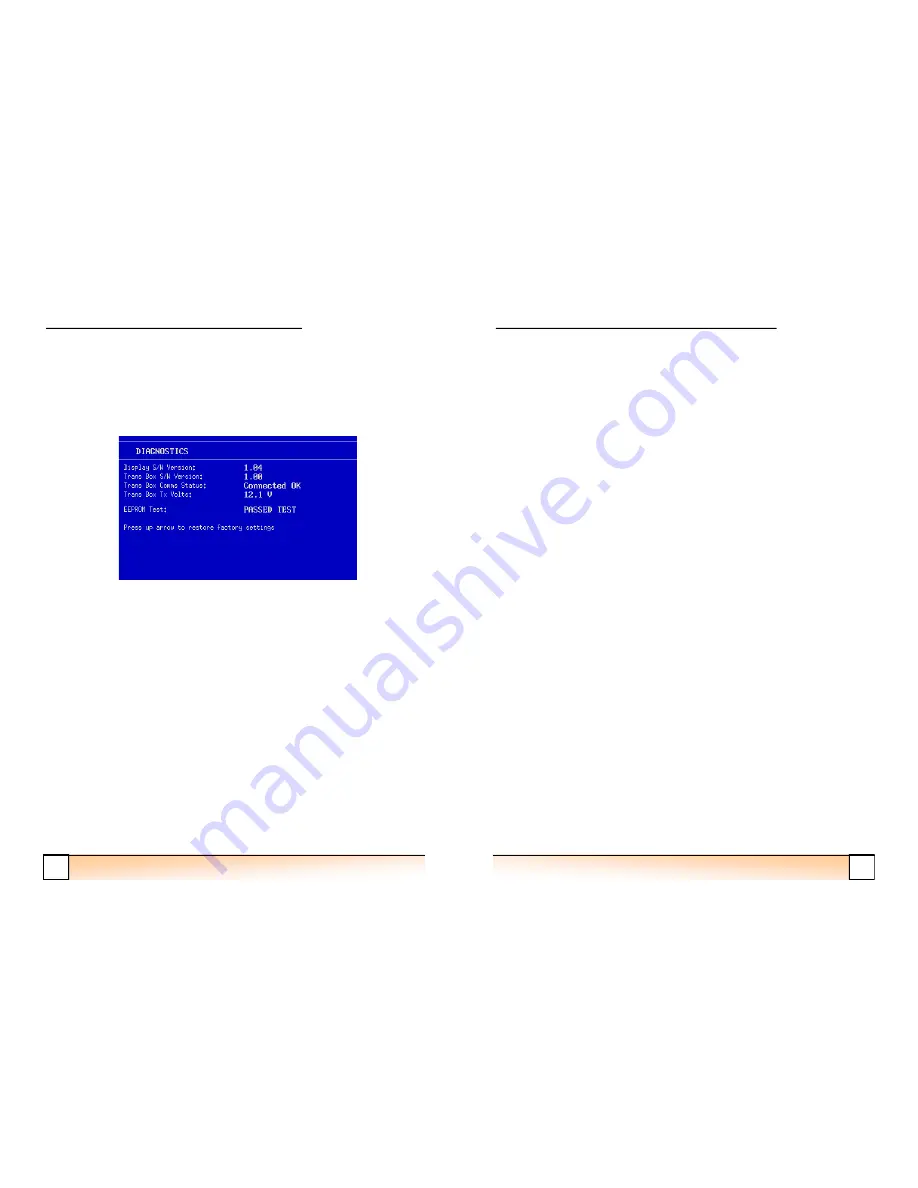

Diagnostics

This screen displays some diagnostic information about the unit. It shows the

software version of both the transmitter box and the display, the status of the

communications link with the transmitter box, the transmitter dc voltage supply and

also tests the settings memory on the display (EEPROM).

Diagnosic Data

‘

Trans Box Comms Status

’

should read

‘

Connected OK

’.

Any other messages mean

an error has occured on the communications link with the transmitter box. If this is

the case, the user should ensure that the transmitter box has power and the data link

cable is connected securely at both ends (transmtter box and display).

‘

Trans Box Tx Volts

’

should read approximately 12 Volts. If the transmitter box

supply voltage is at exactly 12 Volts, then the Tx Volts should be about 9

-

10 Volts.

This will result in slight reduced peformance but should still perform well. If 14 Volts

or more are supplied to the transmitter box, maximum transmit power will be

achieved.

Factory settings can be restored by pressing the up arrow key on this page.

23

FLS Platinum Instruction Manual

FLS Platinum Installation

Interference

Other depth sounders especially those that operate at 200 kHz must be wired so

they can be switched off

if interference occurs. (This may appear as

‘

submarine

’

like echoes coupled with a reduction in sensitivity).

Applying Power

When power is applied to to FLS Platinum system, 2 LEDs on the transmitter box

show the status of power and the communications link to the display unit.

The left LED shows power is reaching the box and this should be lit as soon as power

is applied to the transmitter box.

The right LED should also light upon applying power to the transmitter box. If

successful communication with the display is made, the LED will flash to show that

the display unit is in FLS Mode and that the transmitter box is receiving transmission

requests from the display. If this LED is not flashing, check that the display has

power connected and is switched on

-

and that the 12m data cable is connected

properly at both ends.

Maintenance

Keep transducer

‘

O

’

rings and locking ring thread well greased with a silicone grease.

Protect plugs and cables from chafe. Clean the transducer face regularly and check

for barnacles etc. With care, this may be done afloat. If you have never done this

before, phone us first! You may anti

-

foul the transducer. Avoid long term exposure

of the LCD to direct sunlight.