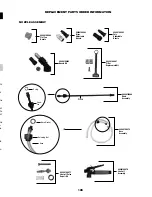

1) Assembled shut-off valve (Figure 1).

2) Remove the retaining pin (A) (Figure 2) place the notched

end of the retaining pin on a hard surface and push down.

Remove the retaining pin and slide the handle off the valve

stem.

3) Remove the retaining nut (o-ring attached), spring, and valve

stem (B) (Figure 3). Replace worn parts. Lubricate the O-rings and

reassemble by reversing the steps above. Place the handle groove

in the slotted area of the valve stem and make sure the locking clip

is positioned in the neutral position (see “Helpful Spraying

Information” section). Insert the retaining pin. Push down on the

handle a few times to distribute the lubricant evenly. Check filter

(C) in end of shut-off valve for debris. Remove filter and flush

with water to clean out.

DISASSEMBLING AND REPAIRING THE SHUT OFF VALVE

9E

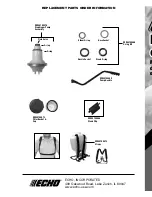

ASSEMBLAGE DE LA BUSE

Figure (1-2)

Dévissez le bouchon de la buse

(1)

du corps de la buse

(3)

avec l'écrou de blocage

(2)

bien

installé au coude

(5)

. Dévissez l’écrou de blocage

(2)

. Poussez le corps de la buse

(3)

avec le

joint d'étanchéité de la buse

(4)

hors de l’écrou de blocage

(2)

. Pour réinstaller la buse,

inversez les instructions précédentes.

Figure 3

Dévissez l'écrou de blocage du coude et poussez l'embout de la buse du ventilateur et le joint

d'étanchéité hors de l'écrou de blocage. Pour réinstaller la buse, inversez les instructions précédentes.

APPLICATIONS ET UTILISATION POUR VOTRE PULVÉRISATEUR

Évitez si possible d'utiliser un pulvérisateur à des fins de nettoyage général si vous l'avez déjà utilisé

pour des produits chimiques de protection des végétaux ou des herbicides. Si un pulvérisateur a été

utilisé pour protéger les plantes ou pour un herbicide, nettoyez le bien (voir la section de nettoyage) avant

de l'utiliser.

Nourriture de plantes :

utilisez différents motifs de pulvérisation pour une nourriture optimale des

feuilles ou pour l’application de pesticides et de fongicides.

Herbicides:

réduisez les mauvaises herbes et les plantes indésirables, mais évitez d'utiliser le même

pulvérisateur pour nourrir ou protéger les plantes sans bien nettoyer (voir la section de nettoyage)

d'abord le pulvérisateur.

Utilisation résidentielle générale :

appliquez des détergents, du vinaigre, des solutions de

nettoyage, de l’eau chaude (sans dépasser 49 °C/120 °F) ou des produits chimiques de nettoyage

résidentiel non toxique pour les tapis, les planchers, les murs, le verre, les comptoirs et les plafonds.

N’utilisez PAS de pulvérisateur utilisé avec des herbicides, des pesticides ou autres produits chimiques

toxiques pour les applications résidentielles.

Utilisation extérieure générale :

utilisez le pulvérisateur pour nettoyer les fenêtres ou avec un

détergent pour le nettoyage général. Les autres applications incluent des agents de préservation du bois,

des cires, un produit d’hydrofugation et des agents de blanchiment résidentiel dilué (maximum de

solution à 1 mesure d’agent de blanchiment résidentiel pour 9 mesures d’eau).

INFORMATION D'UTILISATION ET DE COMPOSANTS DU PULVÉRISATEUR

2F

3. Corps de

la buse

2. Écrou de

blocage

5. Coude

4. Joint

d'étanchéité

de la bue

Figure 1

Figure 2

Figure 3

1. Bouchon de la buse

de poly

1. Bouchon de la buse

de laiton

Coude

Joint

d'étanchéité

de la bue

Embout de la buse

du ventilateur

Écrou de blocage

2. Écrou de blocage

3. Corps de

la buse

4. Joint

d'étanchéité

de la bue

5. Coude

Figure 5

7. At this point the filter cartridge in the pressure chamber base can be

removed with pliers and cleaned (fig 4).

8. The pressure chamber o-ring can also be replaced. DO NOT stretch the

o-ring over the bottom flange. Assemble the o-ring over the top of the

chamber. Apply petroleum jelly to the o-ring before reinstalling pump

asembly into the tank (fig. 3b).

9. Reassemble backwards from step 6 thru 2, performing each step in

reverse. Note: there is a notch/tab combination in the pump

assembly/tank to be used for alignment (fig. 5).

Figure 4

Pump Assembly

Notch

Tank tab

ASSEMBLAGE DES TUBES

1. Assurez-vous que le joint torique est installé à l’extrémité du tube. Insérez le tube dans

le robinet d’arrêt.

2. Tournez et resserrez l'Ècrou de blocage dans le sens horaire sur le robinet d'arrÍt.

Tube

Robinet

d'arrêt

Joint torique

Écrou de blocage

Figure 1

Figure 2

Figure 3

C

Valve

Stem

A

B